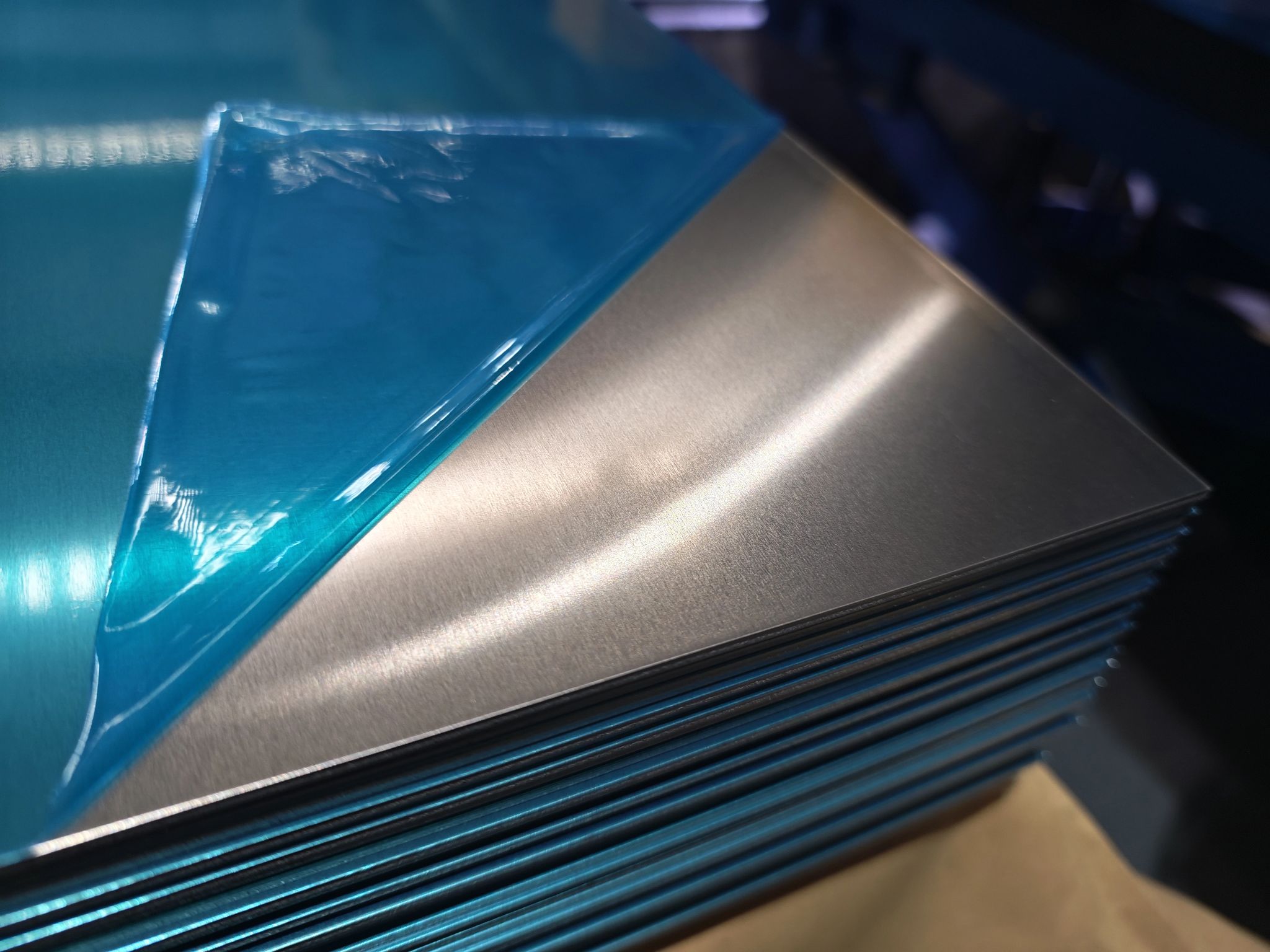

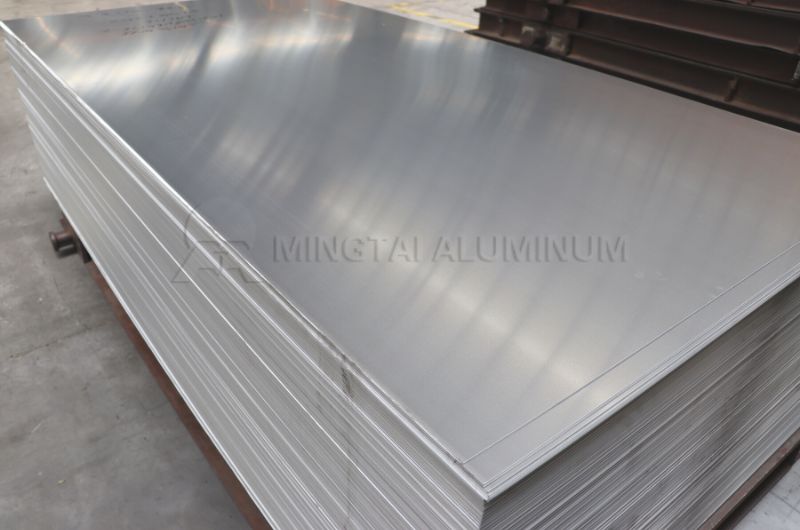

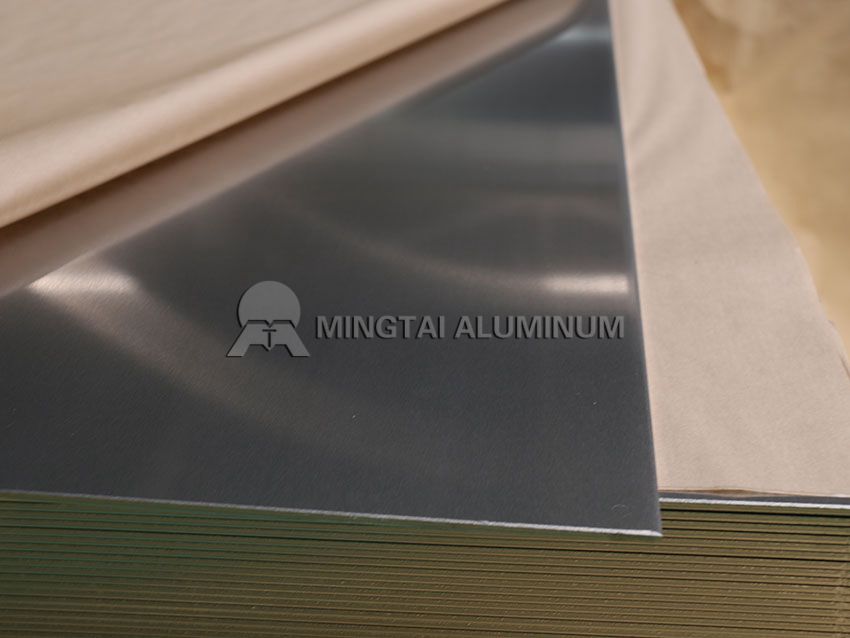

1060 aluminum sheet manufacturer

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

1060 aluminum sheet processing reinforcement is also called cold work hardening, which is cold deformation processing of metal materials below recrystallization temperature, such as forging, calendering, drawing, stretching, etc., when cold deformation, the internal dislocation density of the metal increases, and intertwined with each other. And form a cell structure, hindering the movement of dislocations. The greater the degree of deformation, the more serious the dislocation entanglement, the greater the deformation resistance and the higher the strength. The degree of strengthening after cold deformation varies with the degree of deformation, the deformation temperature of the 1060 pure aluminum plate, and the nature of the material itself. When the same material is cold-deformed at the same temperature, the greater the degree of deformation, the higher the strength and the lower the plasticity. Solid solution strengthened aluminum plate.

The addition of certain alloying elements to the pure aluminum 1060 hot-rolled aluminum sheet to form an infinite solid solution or a finite solid solution not only achieves high strength, but also achieves excellent plasticity and good press workability. The alloying elements commonly used for solid solution strengthening in general aluminum alloys are elements such as copper, magnesium, manganese, zinc, silicon, and nickel. Generally, the alloying of aluminum forms a limited solid solution, and binary alloys such as Al-Cu, Al-Mg, Al-Zn, Al-Si, and Al-Mn form a limited solid solution, and both have a large limit solubility. Large solid solution strengthening effect 1060 pure aluminum plate.

1060 aluminum plate performance:

1060 aluminum sheet manufacturer 1060 aluminum plate is formed by adding a small amount of copper element, which has good forming processing characteristics, high corrosion resistance, good weldability and electrical conductivity. Widely used in products with low strength requirements, such as chemical instruments, sheet metal parts, deep drawing or spinning concave vessels, welded parts, heat exchangers, clock surfaces and discs, nameplates, kitchen utensils, decorations, reflective appliances, etc. .

1060 aluminum sheet manufacturer heat treatment process:

1060 pure aluminum plate rapid annealing: heating temperature 350 ~ 410 ° C; with the effective thickness of the material, the holding time is between 30 ~ 120min; air or water cooled. High temperature annealing: heating temperature 350 ~ 500 ° C; finished product thickness ≥ 6mm, holding time is 10 ~ 30min, <6mm, heat through; air cooling. Low temperature annealing: heating temperature 150 ~ 250 ° C; holding time is 2 ~ 3h; air or water cooling.

1060 aluminum sheet manufacturer offers 1060 aluminum price:

The price of 1060 aluminum plate: The price of 1060 aluminum plate is not static. There are two main factors affecting the price of aluminum plate. First, the price of aluminum ingot, the price of aluminum ingot can be found, and it is changed according to market supply and demand; The second is the processing fee, and the processing fee is based on the specifications of the aluminum plate. Henan Mingtai Aluminum Co., Ltd. is a 1060 aluminum sheet manufacturer with long-term supply of 1060 aluminum sheets. The company has been engaged in the aluminum processing industry for more than 20 years. The company’s products cover 1 to 8 series of aluminum alloy products. The company’s products are exported to North America, Europe, Australia, Southeast Asia, the Middle East and other overseas markets, and the foreign trade share is growing rapidly.