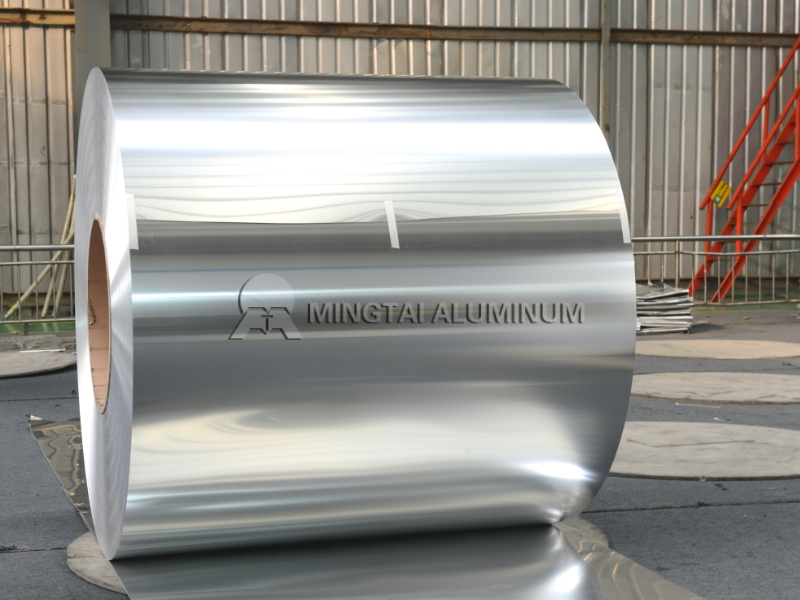

2A16 aluminum coil

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Introduction to 2A16 aluminum coil:

2A16 aluminum coil is an alloy with higher strength in hard aluminum. It is characterized by high strength at normal temperature and high heat strength. It is a heat-resistant hard aluminum. The alloy has high plasticity during hot deformation, and tends to form a coarse crystal ring in the extruded semi-finished product, which can be heat-treated and strengthened, and is used in quenching and artificial aging conditions.

2A16 aluminum coil use process:

2A16 aluminum coil is used for axial compressor blades of turbojet engines with working temperature of 200-300 °C and other die forgings which work at high temperature and whose alloy properties can meet the structural requirements. They are generally used as the main bearing structural materials.

2A16 Aluminum profile This is a heat-resistant hard aluminum which is characterized by a low strength at normal temperature and a high creep strength at high temperatures. The alloy has a high plasticity in the hot state without extrusion. Pressure effect, heat treatment strengthening, spot welding, seam welding and argon arc welding have good performance, the tendency to form cracks is not significant, and the weld seam is still airtight. The corrosion stability of the weld is low, the corrosion stability of the aluminum-clad sheet is still good, and the corrosion resistance of the extruded semi-finished product is not high. To prevent corrosion, the anodizing treatment or painting protection should be used to protect the fen.

2A16 Aluminum profile is used for working parts below 250-350 °C, such as axial II shrinking machine blades, discs, plates for welding parts working at normal temperature and high temperature, such as containers, airtight compartments, etc.

2A16 aluminum coil advantages:

1. Good corrosion stability

2. The weldability is better.

3. Good machinability.