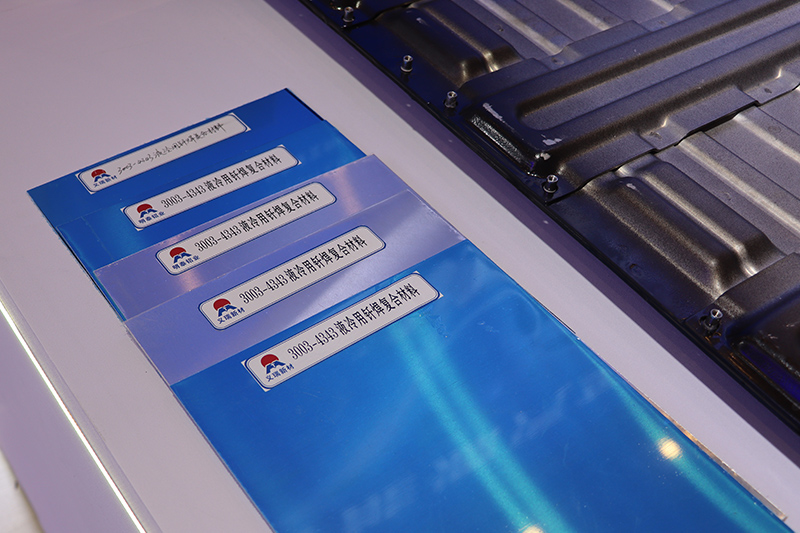

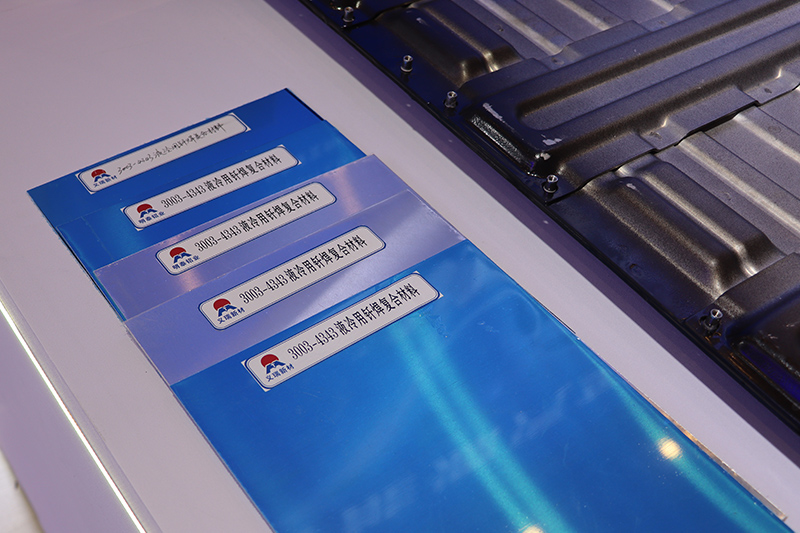

3003 mod+4343 aluminum alloy composite material for liquid cooling plate

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

3003 mod+4343 aluminum alloy composite material is a special type of aluminum alloy material widely used in automotive water cooling and heat dissipation systems. This composite material is usually brazed from two O-state aluminum plates, ensuring the stability and safety of power batteries in high-temperature working environments.

3003 mod+4343 aluminum alloy

3003 mod+4343 aluminum alloy itself belongs to the aluminum manganese series alloy, also known as rust proof aluminum plate. It still has good rust prevention ability in humid environments.

In addition, 3003mod aluminum alloy also has the following characteristics:

1. Low density and light weight provide ideal materials for automotive lightweighting.

2. Good corrosion resistance, suitable for use in humid or corrosive environments.

3. Easy to process, can meet various complex design and application requirements.

4. Good brazing performance, suitable for assembly of complex liquid cooling systems.

4343 aluminum alloy

4343 aluminum alloy, also known as Al-Si alloy, is a commonly used aluminum silicon alloy. It is mainly composed of aluminum and silicon, with silicon content generally around 10%. In addition, it also contains small amounts of elements such as copper, magnesium, and zinc.

This aluminum alloy has the following characteristics:

1. High strength: The strength of 4343 aluminum alloy is higher than that of general aluminum alloy, which makes it widely used in many occasions that require high-strength materials.

2. Good corrosion resistance: Due to the presence of silicon element, 4343 aluminum alloy has good corrosion resistance and is suitable for use in humid or corrosive environments.

3. Strong weldability: The melting point of 4343 aluminum alloy is between 620-660 ℃, which allows it to be connected to other metals through brazing, meeting various complex design and application requirements.

It is worth noting that brazing is a common metal connection method that is suitable for various metal materials, including aluminum alloys.

In addition, 4343 aluminum alloy and other types of aluminum alloy brazing plates, such as 3003/7072, are composite plates composed of aluminum manganese alloy core material and aluminum based brazing material coating layer. Compared with traditional aluminum alloy brazing plates, these new aluminum alloy brazing plates have better corrosion resistance and brazing performance.

Mingtai Aluminum successfully developed the production process of water-cooled plate brazed composite materials as early as 2008, becoming a leading manufacturer. Mingtai Aluminum is renowned for its commitment to excellence, providing top-notch aluminum plates and composite materials that meet strict industry standards.