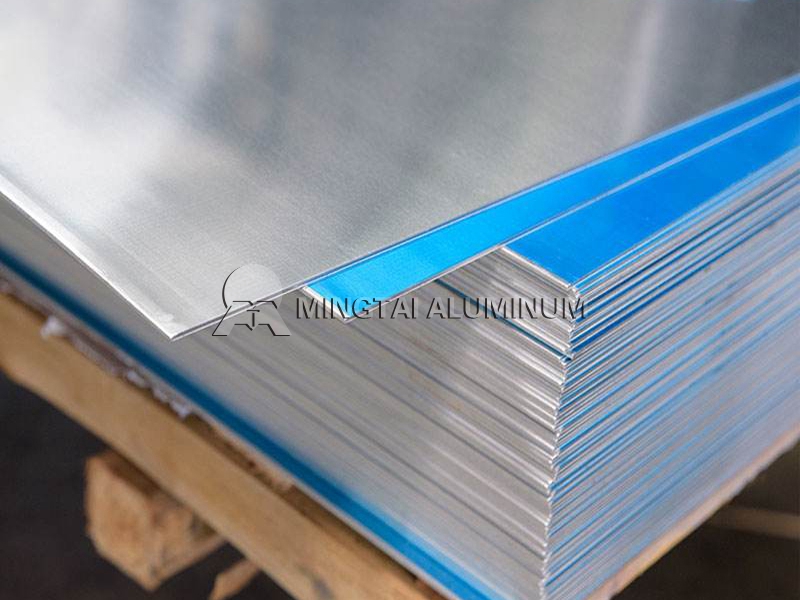

3004 hot-rolled aluminum plate for aluminum honeycomb core panel

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Aluminum honeycomb panels, as a new type of material, have been widely used in fields such as construction, aerospace, and transportation due to their unique structure and excellent performance. The honeycomb aluminum panel adopts a “honeycomb sandwich” structure, consisting of upper and lower panels and a honeycomb core in the middle. It has the characteristics of light weight, high strength, good stiffness, strong corrosion resistance, and stable performance.

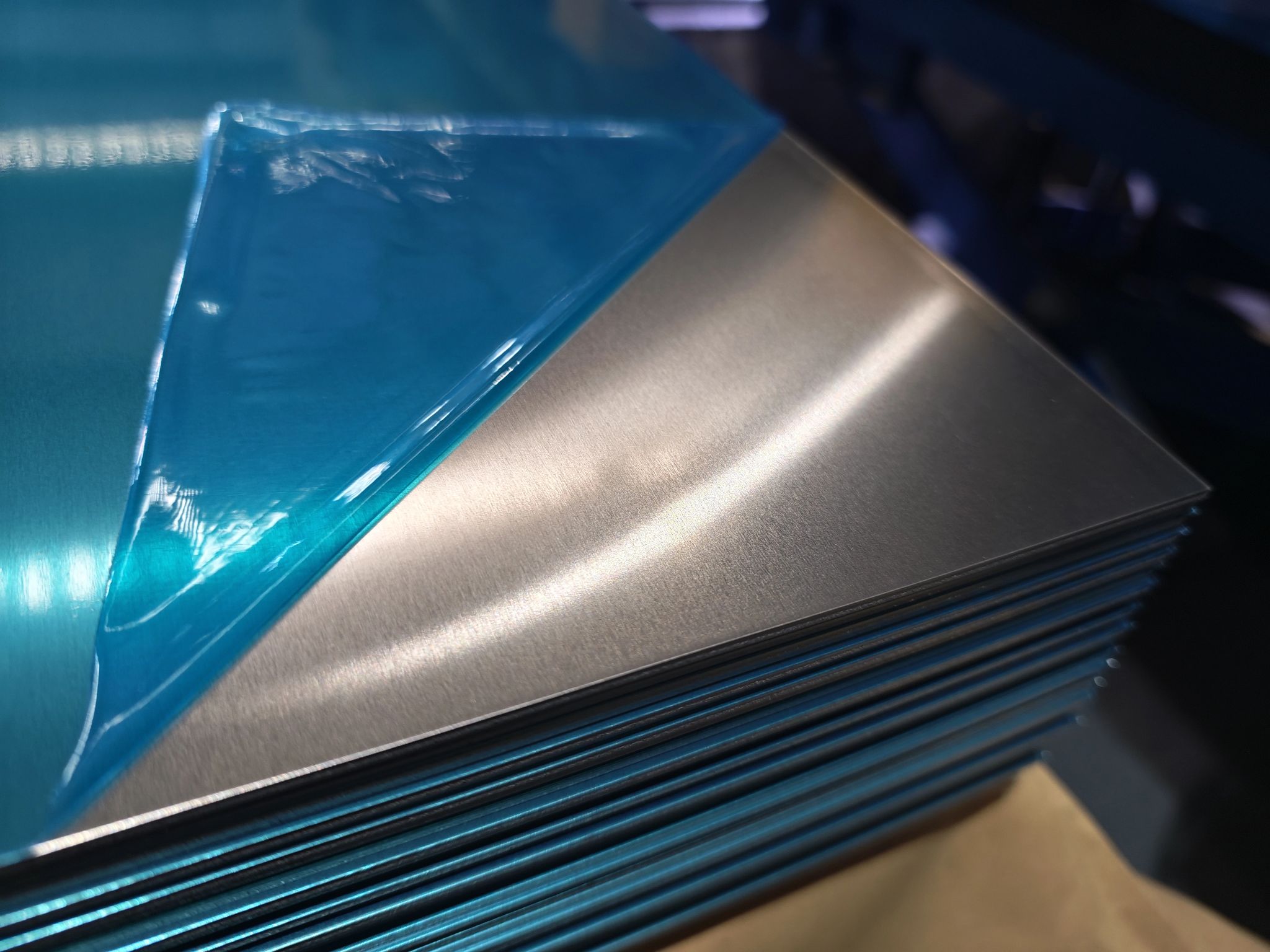

For an entire aluminum honeycomb panel, the core material accounts for 15% and the panel accounts for 85%. Traditional aluminum honeycomb panels mainly use 1-series aluminum panels, with a thickness limit of 0.55mm. At present, many manufacturers choose to use 3-series aluminum alloys, such as 3003 aluminum plate, 3004 aluminum plate, etc., which belong to aluminum manganese alloy and have higher strength compared to 1-series, which can improve the bearing capacity and impact resistance of aluminum honeycomb panels. At the same time, using 3-series aluminum alloy can also reduce the thickness of the material, and there will be no honeycomb shaped marks during hot or cold pressing bonding in the later stage, ensuring surface aesthetics.

The structural characteristics of aluminum honeycomb panels are also the key to their superior performance. It is composed of two layers of aluminum panels and a honeycomb structure in the middle, which makes the panel have excellent performance such as lightweight, high strength, sound insulation, and heat insulation. When subjected to force, the honeycomb structure can effectively disperse pressure, improve the load-bearing capacity and stability of the panel. In addition, aluminum honeycomb panels also have excellent properties such as fire resistance, moisture resistance, and corrosion resistance, which can adapt to various harsh environments.

3004 hot-rolled aluminum plate compared to 3003 hot-rolled aluminum plate:

3004 hot-rolled aluminum plate is a universal alloy with excellent corrosion resistance. Its composition is similar to that of 3003 aluminum plate, but a small amount of magnesium is added to improve its strength.

What are the performance advantages of 3004 hot-rolled aluminum plate

1. Has good formability and good processing characteristics.

2. High corrosion resistance and good weldability.

3. Good deep drawing ability and high plasticity.

Technical parameter

Material status: O, H12,H14,H16,H18,H19,H22,H24,H26,H28,H112

Thickness (mm): 0.1-500

Width (mm): 100-2650

Length (mm): 500-16000