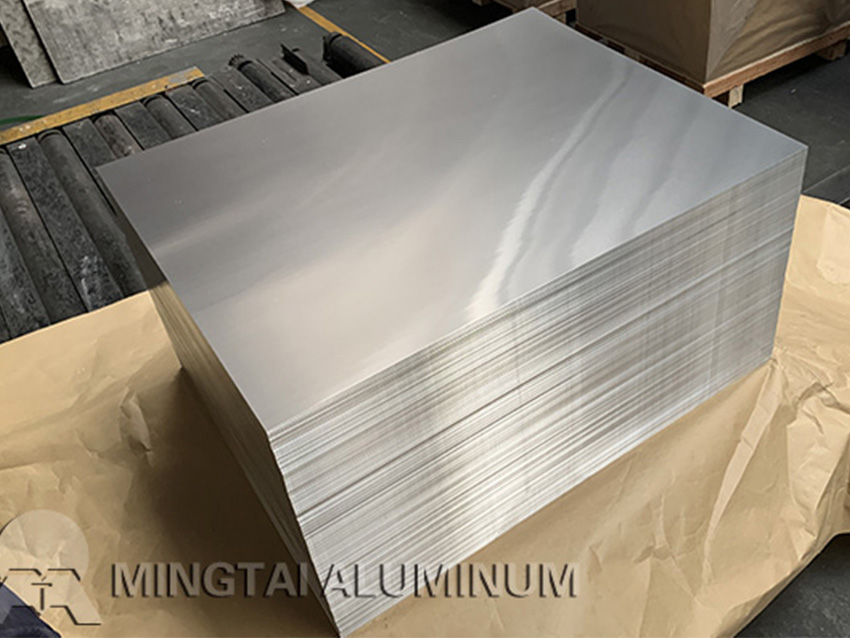

5083 h32 Aluminum Sheet

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

5083 h32 Aluminum Sheet Overview:

5083 h32 aluminum sheet refers to work hardening 5083 aluminum plate, after low-temperature heat treatment or due to the heating in the process of processing, so as to achieve stable mechanical properties, and obtains 1/4 Hard. The strength of 5083 alloys in H32 temper, is slightly stronger than that in soft annealed temper O condition, but lower than that in marine tempers H116 and H321. It’s not difficult to find that all flat-rolled mill alloys are supplied with stable properties. This is usually achieved by a stable thermal treatment as the last operation, which results in the H32 or H321 tempers.

Features of 5083 h32 Aluminum Sheet:

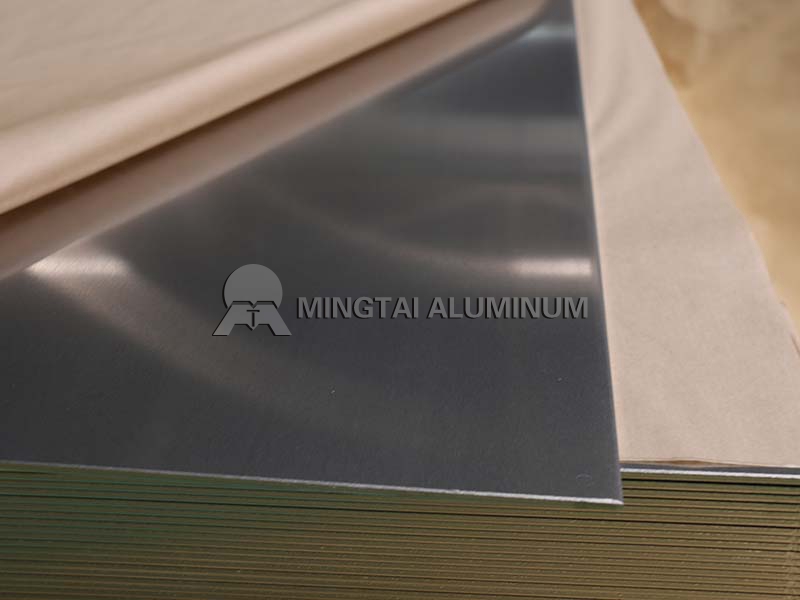

Cold Working:Like all the 5000-series high Mg alloys, 5083 h32 aluminum sheet achieves a high strength by cold working. And after cold work, alloy 5083 H32 can spontaneously age-softens at room temperature immediately, but will eventually reach a stable condition.

Corrosion Resistance: Similarly, 5083 h32 aluminum sheet also exhibits excellent corrosion resistance in a wide range of atmospheric environments, in food processing and architectural applications.

Other Performances: The 5083 h32 aluminum sheet with GMAW and GMAW welding methods, can produce structural welds better. But the machinability is poor due to its high strength. For the plasticity, is good in semi-cold hardening, but low in cold hardening.

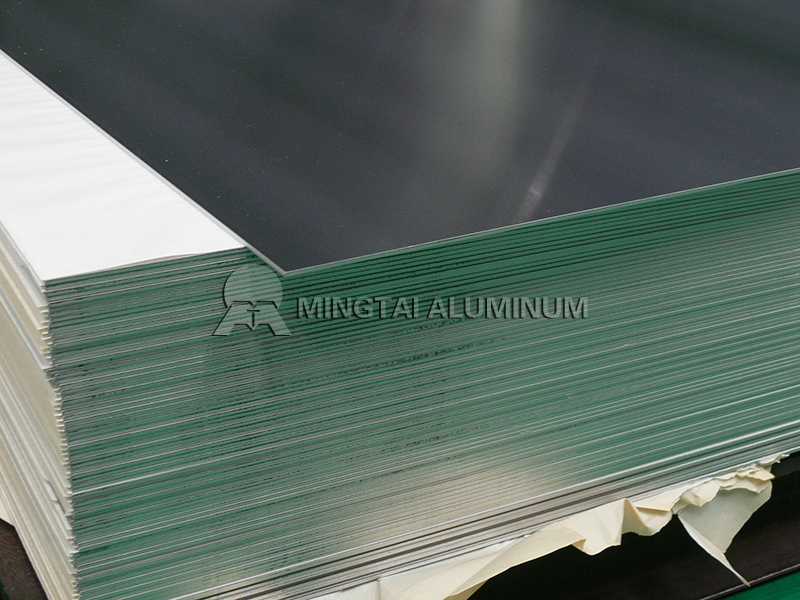

Practicality of 5083 h32 Aluminum Sheet:

In general, 5083 h32 aluminum sheet is widely used in the field of Architectural, Structural, Light-duty marine, Transportation, Manufacturing, etc.

Specifically, For the Boat/ shipbuilding, Pressure vessels, Rail and other vehicles, Bus skin, Various structural applications, LNG storage tank, flange, GIS high-pressure switch shell, Precision machining, etc., 5083 h32 aluminum sheet all has significant practicality.

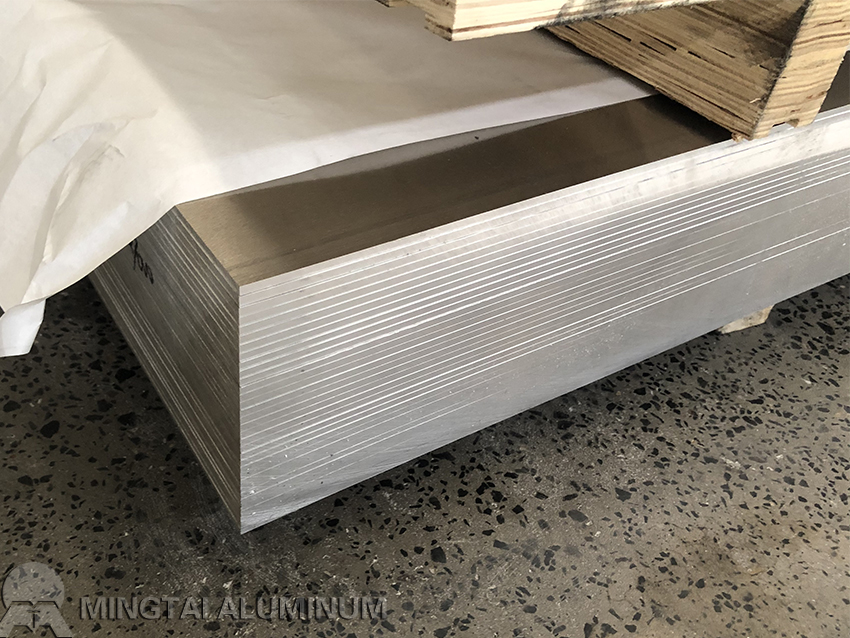

Mechanical Parameters of 5083 h32 Aluminum Sheet:

| Alloy | Spec | Tensile | Yield Strength | Elongation(% in 50mm) | ||

| minimum for sheet or plate thicknesses shown | ||||||

| & Temper | Strength (MPa) |

0.2% Proof (MPa) |

All gauges (Note 2) | 5.0- 12.5mm |

6.31- 80.0mm |

|

| 5083-H32 | B209M | 305-385 | 215 min | - | 12 | - |

Ps: Properties specified for temper H32 or O varies slightly depending on sheet or plate thickness.

Technical Parameters of 5083 h32 Aluminum Sheet:

| EMRNTS | Mg | Si | Fe | Ti | Cu | Mn | Cr | Zn | Others | Others |

| Each | Total | |||||||||

| CONTENT (WT%) | 4.0-4.9 | ≤0.4 | 0.4 | ≤0.15 | ≤0.1 | 0.4-1.0 | 0.05-0.25 | 0.25 | 0.05 | 0.15 |

| Alloy Grades | 5083 Aluminum Series | |||||||||

| Material Temper | H32 | |||||||||

| Thickness | 0.1-500mm | |||||||||

| Width | 20–2650mm | |||||||||

| Length | Customize | |||||||||

| Typical product | Architectural, Structural, Light-duty marine, Transportation, Manufacturing, etc | |||||||||