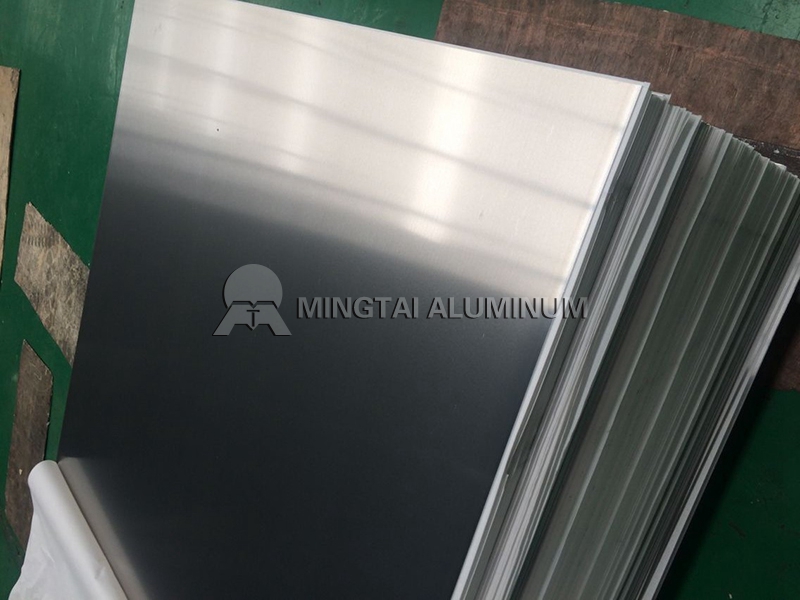

6063 Extruded Aluminum for Structural Parts

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Introduction to 6063 Extruded Aluminum

6063 aluminum plate belongs to forged aluminum alloy, and belongs to deformed aluminum alloy in the alloy group. The first digit 6 in the grade indicates that the alloy uses magnesium and silicon as the main alloying elements, and Mg.Si phase as the strengthening aluminum. Alloy, in addition, 6000 series aluminum is also the most important extruded alloy, 6063 extruded aluminum is one of its representatives. According to a number of data, 6063 aluminum alloy is far lower than ordinary carbon steel Q235 in terms of strength, hardness and modulus of elasticity, but the density of 6063 aluminum alloy is about 1/3 of Q235. Obviously, this is for moving components in the machine It is very ideal, according to the second law of dynamics: the mass maa inertial force F = maa (where the acceleration a is given by the system motion, that is a = const) This is 6063 extruded aluminum can become some important structural parts main reason.

In addition, the strength index of 6063 extruded aluminum under the condition of artificial failure (CS) and its good corrosion resistance also paved the way for it to become the basic part of some machines. For a long time, in view of the low mechanical index of 6063 aluminum sheet, people only considered its light weight and corrosion resistance, and only used 6063 extruded aluminum to make some static components. For example, a common aluminum alloy fence is used on internal combustion engine components only to make high temperature and corrosion resistant engine pistons. But with the acceleration of global industrialization, the idea of 6063 extruded aluminum replacing heavy carbon steel for machine structural parts is being realized step by step.

6063 Extruded Aluminum Properties and Use

(1) The density of 6063 extruded aluminum is uniform, and the fiber direction is uniform. And when the profile design of the profile products made of 6063 aluminum sheet is reasonable, the internal tissues are free of looseness, pores and cracks. It laid a good foundation for the basic parts of the machine, which enabled us to boldly adopt it in various situations and equipment and pharmaceutical machinery.

(2) When the working environment of the moving parts of the machine requires corrosion resistance, 6063 extruded aluminum is an ideal material. Because 6063 aluminum alloy has better oxidation performance than 6061 aluminum sheet, it can form a dense oxide film (Al2O3) on the surface. , To protect itself from corrosion, has a strong ability to resist corrosion.

(3) For some important machine parts, such as gearboxes of automobiles and motorcycles, short-range cylinder blocks with a pressure of less than 1 MPa and a cylinder bore of less than 50, 6063 extruded aluminum is currently in large quantities due to its light weight and easy molding 6063 extruded aluminum is used.

Significance of 6063 Extruded Aluminum for Structural Parts

(1) 6063 extruded aluminum has a smooth appearance, corrosion resistance, and does not require coating the surface. In addition, 6063 aluminum alloy is light in weight, has small impact force and low power consumption as a moving component, and the related bearings and structural parts have a long service life, which is economical and environmentally friendly.

(2) When the proportion of 6063 extruded aluminum parts in the machine is greatly increased, the noise of the factory will be reduced by at least 10 decibels, which will cause less environmental pollution and benefit the physical and mental health of the staff. And its depreciation rate is low and the recovery rate is high.

(3) 6063 extruded aluminum that has been artificially aged has replaced a large number of cast iron parts and has been proven to perform well after years of use.