8011 aluminum foil for food packaging, pharmaceutical packaging

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

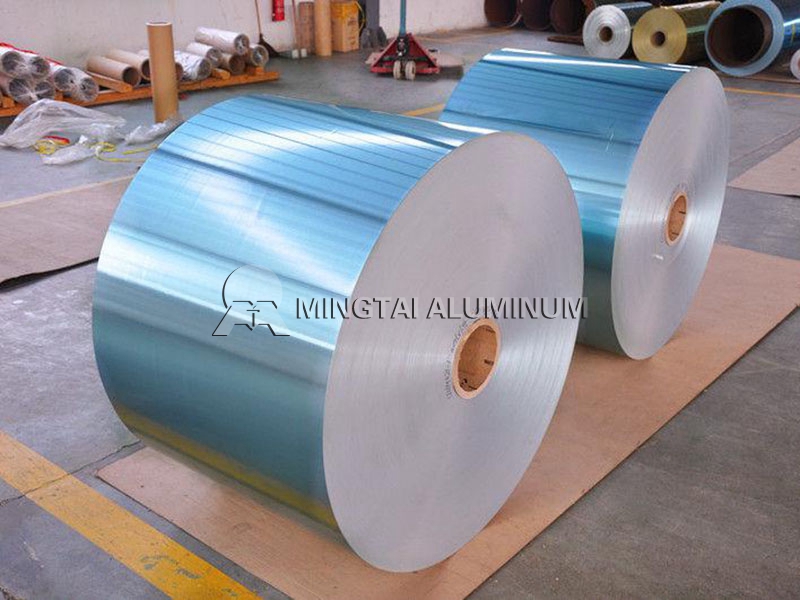

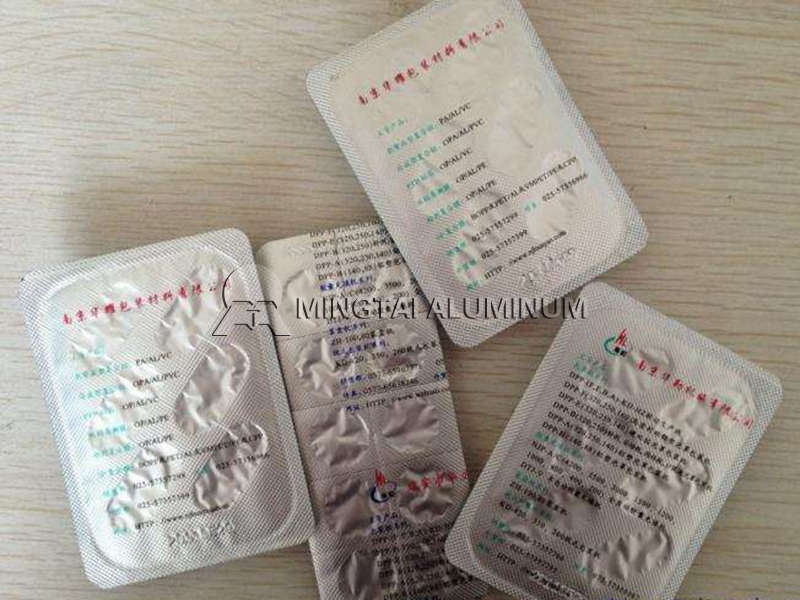

Among the commonly used 1/3/8 series aluminum foils, 8 series aluminum foil is commonly used in food, pharmaceutical packaging and electronic appliances. Among them, 8011 aluminum foil and 8021 aluminum foil are widely used. Although 8011 aluminum foil has a stable production base in China, the production standard for the use of pharmaceutical foil is very high, and it is not the manufacturer that can meet the requirements.

8011-H18 foil is often used to adhere to the back side of plastic packaging materials. The aluminum foil after compounding, printing and coating is widely used as a packaging material. The surface is required to be clean, uniform in color, free of spots, and flat without pinholes. It has excellent moisture resistance, shading and high barrier ability, strong mechanical properties, high anti-blasting performance and strong puncture and tear resistance. Non-toxic, tasteless, safe and hygienic.

The cold-formed aluminum foil of the 8021-O state is pressed and formed into a sealed package after deep drawing. It has strong mechanical properties, high anti-blasting performance and strong puncture and tear resistance. Excellent moisture resistance, shading and high barrier properties. The surface is clean, the color is uniform, there is no spot, no oil, and there is no pinhole. Bacteria, mold and other tests, heavy metals do not exceed 0.2 million parts per million, strict implementation of industry standards, to ensure safety and health.

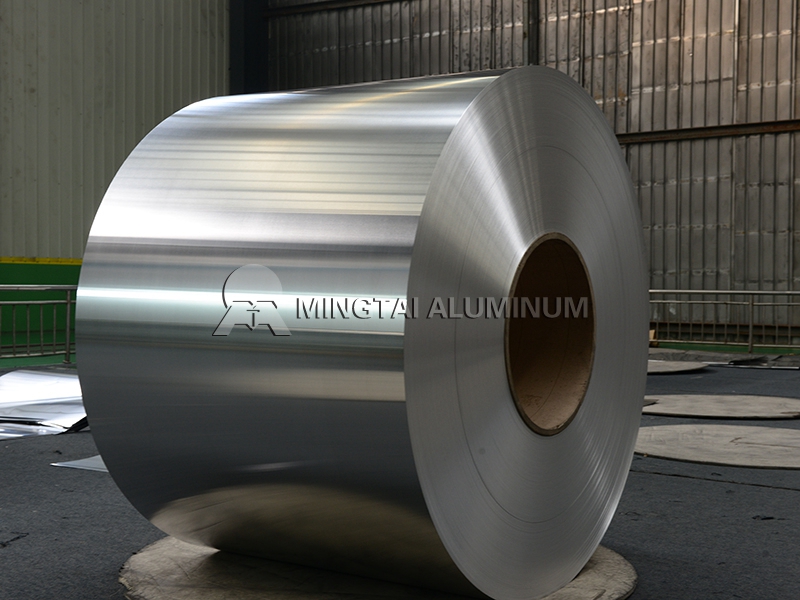

Nowadays, food safety has become a concern of everyone. Especially the safety of milk powder on the market is particularly important. The safety of milk is not only a problem of the raw materials needed for milk powder. The external packaging is also very important. The milk powder is covered with clean and sanitary aluminum foil. Paper is very important.

At present, the milk powder cover which is directly in contact with the milk powder on the market is mainly made of aluminum foil paper, and mainly functions as a moisture proof and a seal. As the milk powder cover, the aluminum foil easy to tear cover is composed of an inner cover and an outer cover. The inner cover is an easy-to-tear cover structure, and a pull ring is attached to the aluminum foil of 50-60 mm thick, and the outer edge of the aluminum foil is heat-sealed or adhered to the cover ring of the tin-plated steel plate, and the ring is tightly fixed with the can body to make the inner cover and the inner cover The tanks are connected. When the aluminum foil easy-to-open cover is opened, the aluminum foil can be completely torn off along the can edge as long as the tab is pulled up with a finger and pulled up. The outer cover protects the inner cover and can reclose the can after the inner cover is opened.

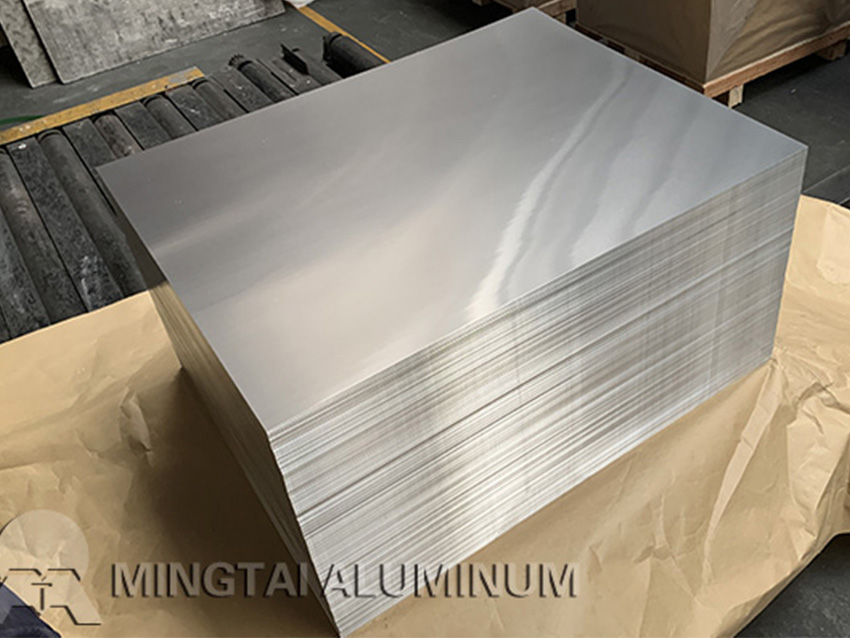

The easy-to-tear cover of milk powder has higher requirements on the food grade and product quality of aluminum foil. Taking 8011 aluminum foil produced by Mingtai Aluminum as an example, the 8011 aluminum foil of Mingtai Aluminum meets the food grade requirements, and the layout is flat; the layout requirements are strict, no Black oil spots, scratches, small black wires, bright lines, roller prints, bumps, mosquitoes, etc.; trimming quality, no burrs, towers, enamel layer energy, ruffled edges, flanging, bumps and lights; brush water Must meet Class A standards; package moisture-proof to avoid oxidation. The thickness of the finished product is controlled within ±4%.

Mingtai Aluminum’s 8011 aluminum foil meets the above requirements, and has high hardness, strong tension, excellent plasticity, and is suitable for packaging of any shape. The shading effect is good, it can avoid sunlight and other light, and there is no penetration at high temperature and low temperature.

The 8011 aluminum foil produced by Mingtai Aluminum Co., Ltd. enjoys a good reputation and reputation in both domestic and foreign markets. This stems from the strict control of product quality by Mingtai Aluminum. Henan Mingtai introduces the flying shears imported from South Korea and the domestic leading Kaiping shears, and strictly controls the processing technology of the products. The tensile strength of the aluminum substrates for food packaging can reach 120-140MPa, the yield strength is 120-135MPa, and the ear production rate 0-2%, thickness difference: +/- 0.005, and the degreasing is clean, the surface cause value is >56. Advanced equipment and processing technology, as well as effective quality control system, make Mingtai Aluminum’s 8011 aluminum foil a stable supplier to domestic large food packaging processing plants, and exported to more than 40 countries including Russia, India, Australia, and the United States. area.

Mingtai’s 8011, 8021, and foil have been well received by the market for their superior performance. We provide customers with a comprehensive quality assurance system, from the purchase of aluminum ingots, to the production process, to the quality inspection before leaving the factory, to provide customers with 360-degree worry-free quality inspection packaging, you can rest assured to purchase.