Automotive aluminum | Aluminum alloys in the automotive industry

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

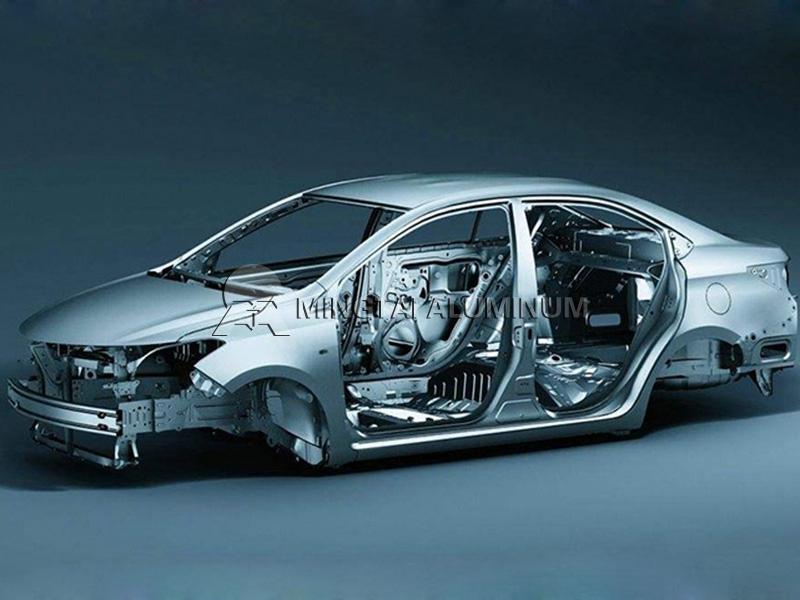

The weight of the car body accounts for almost 30% of the weight of the entire car. Reducing the weight of the car is of great significance for the lightweight development of the car. Relevant data shows that aluminum alloy car body panels can reduce the weight of the car body by 40%-50%. Therefore, in recent years, more and more automobile manufacturers have used aluminum alloy as the body material. In this way, the weight of the vehicle body is reduced, fuel consumption is saved, and pollution is reduced.

At present, automobile lightweighting is an important development direction of the automotive industry. Among the lightweight materials of automobiles, the comprehensive cost performance of aluminum alloy materials is higher than that of steel, magnesium, plastics and composite materials. It is advantageous in terms of application technology, operational safety and recycling. It is an ideal lightweight material.

According to the difference of alloying elements and alloy ratio, aluminum alloy is applied to automobile body, frame, engine cylinder block, automobile fuel tank, cylinder head, piston, intake manifold, rocker arm, engine mount bracket and actuator. Housing, clutch housing, brake parts, and cover housing. Automotive aluminum can effectively reduce the overall weight of the vehicle, save fuel consumption and improve safety.

Automobile lightweighting has been highly sought after by automakers. Even international luxury cars have come up with the idea of boldly proposing all-aluminum bodies. The well-known Jaguar, Audi, Rolls-Royce, etc. are slowly transforming into all-aluminum bodies. This shows that the future of Automotive aluminum is very open. The heart of the car is the engine. The aluminum for the engine has been widely used in the industry in the past few years. The aluminum plate for automobile body and the aluminum plate for automobile fuel tank are also a big market trend.

Aluminum alloy materials commonly used in automobile bodies include 2, 5 and 6 series, of which 6 series alloys are the main force of body panels. The 6-series alloy is a heat-treated reinforced aluminum alloy with high strength, good plasticity and excellent corrosion resistance. Compared with the steel plate, the yield strength and tensile strength of the 6-series 2T4 plate are similar, and the hardening coefficient even exceeds that of the steel plate. At present, 6009, 6010 and 6061 aluminum alloys are widely used in automobile exterior panels and inner panels due to their good plasticity and the ability to achieve artificial aging during the post-forming paint baking process. In addition, the chassis, skeleton, seat, skin, door and other parts of the car can be made of aluminum alloy, which is both beautiful and weight-reducing.

At present, the aluminum plates for automobile fuel tanks commonly used in the market have 5052 aluminum plates, 3003 aluminum plates and 5754 aluminum plates. The aluminum has good oxidation resistance and corrosion resistance, and forms a dense oxide film on the surface of the aluminum, which is well prevented from the outside world. The chemical reaction of the material guarantees the service life of the automobile fuel tank, thus replacing the traditional iron fuel tank and the plastic fuel tank.

Henan Mingtai Aluminum has passed the strict audit of the two stages of Beijing SGS certification organization. In early April 2014, the company obtained the TS16949 quality system certification issued by SGS, which is an important symbol of the company’s products entering the automotive market. The company’s products expand the market space to provide a favorable guarantee.