Mingtai 5052 aluminum plate performance advantages

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

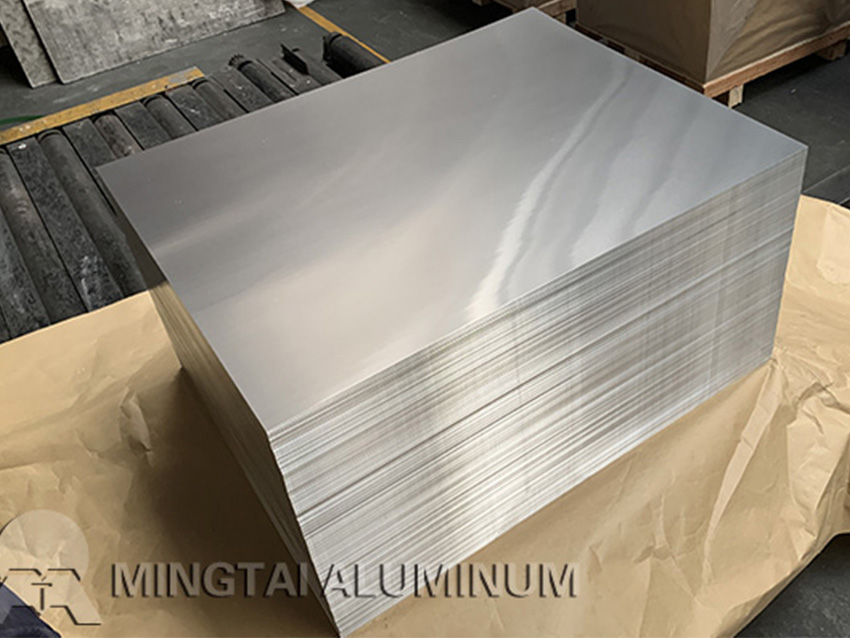

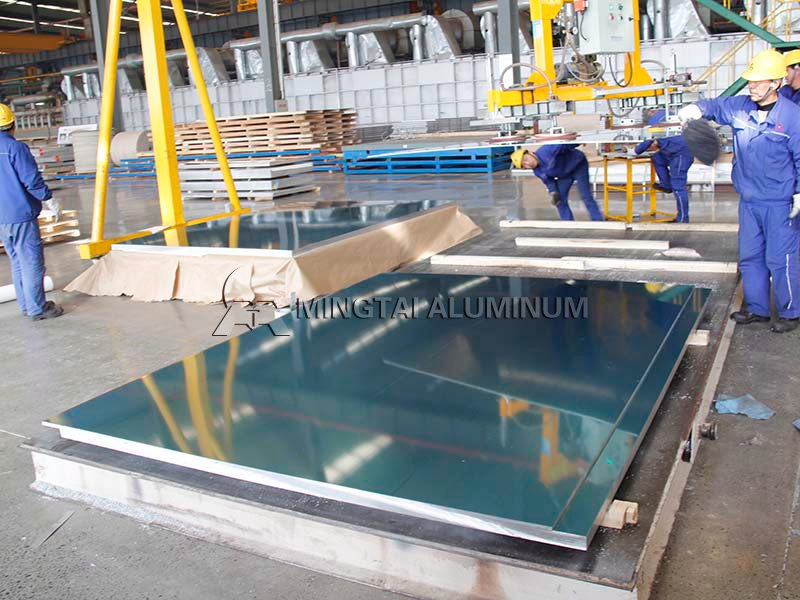

Mingtai 5052 aluminum plate production process:

From the production process, 5052 aluminum plate from semi-continuous ingot, homogenization, sawing, milling, aluminum, heating, hot rolling, annealing, cold rolling, annealing, cold rolling, solution treatment, aging treatment, to shear This series of processes for cutting, leveling, inspection and oil coating constitutes the complete step of the 5052 aluminum sheet production.

Mingtai 5052 aluminum plate manufacturers advantage:

The production process of Mingtai 5052 aluminum plate is very mature. At present, there are dozens of manufacturers engaged in the production of 5052 aluminum plates in China, and Henan Mingtai is one of the representative leading enterprises.

We are a comprehensive enterprise engaged in the R&D and production of aluminum foil and foil. The main products include all alloys of 1-8 series, with an annual production capacity of more than 1 million tons. The 5 series alloys are relatively mature product series and have occupied a stable share in the domestic aluminum processing market for many years.

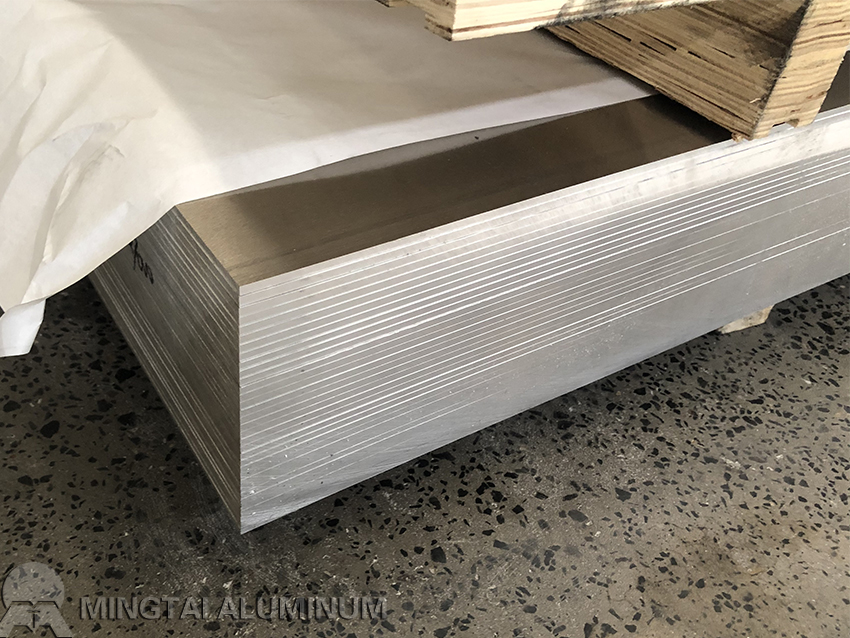

Mingtai 5052 aluminum plate inspection:

5052 aluminum plate is an important product of Mingtai. Therefore, precise production control and strict quality inspection are set to ensure the mature technology and superior performance. For example, in the quality inspection, the three key indicators of the 5052 aluminum plate were accurately tested.

1. Small organization and uniform performance. Especially for ultra-thick plates, the performance in the thickness direction is required to be uniform, and there is no large performance fluctuation. For medium and thick plates and thin plates, there is also no large performance fluctuation in length and width;

2. High dimensional accuracy. It mainly includes thickness precision and width precision, especially the thickness accuracy with the most difficult requirements, which will directly affect the performance and subsequent processing;

The shape of the plate is good. The shape of the plate includes flatness and plate crown. Because both have a great impact on subsequent processing and are irreversible.

Surface treatment process of Mingtai 5052 aluminum plate:

1. Polishing: Overcoming the effects of deburring and brightening the surface, it is divided into chemical polishing and mechanical polishing.

2. Sandblasting: the purpose of aluminum surface treatment is to overcome and cover up some defects in the machining process of aluminum alloy and meet customers’ special requirements on the appearance of products. Glass sand, tungsten sand, etc., showing different feelings, similar to the rough dry texture of ground glass, fine sand can also show high-grade products.

3. Metal electroplating method: it is common, and there is a treatment process of electroplating after polishing.

4, grain: aluminum surface treatment is the mold after the processing of processing, using lathes to process lines, the adult body is very regular texture characteristics.

5, wipe lines: there is called brushed, similar to the car lines, are formed on the surface of smooth continuous lines, the difference is, the car lines for circular lines, wipe lines for straight line.

6. Oxidation (coloring): The use of aluminum surface treatment oxidation is divided into two aspects, enhancing physical properties and achieving coloring purposes. Generally, it is anodized. The purpose is to color, and the second is to increase the surface hardness and improve wear resistance, such as micro-arc oxidation.

7. Spraying: Spray a layer of coating on the surface of aluminum, spray white, spray wood grain, etc., fluorocarbon spray.