Aluminum plate processing and how to judge the quality of aluminum plate

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

During the processing of aluminum plates, the aluminum plates are often broken due to bending work, especially the cracking of anodizing after bending work, which makes many aluminum plate processing enterprises confused, so how to avoid such problems, let us discuss them together.

The Reason For the Fracture of Aluminum Plate Processing

The reasons for the fracture of the aluminum plate are mainly the following points. If we pay attention to the following problems during the processing, the occurrence of the fracture will be greatly reduced.

1.Excessive Aluminum Plate Hardness

Generally, the harder the object, the easier it is to be affected by the external force, so is the aluminum plate. Therefore, we must be careful when choosing an aluminum plate. According to the aluminum plate grade and state, we can choose those products that are easier to bend, like the 1 series 1060 aluminum plate, 3 series 3003 aluminum plate, and 5 series 5052 aluminum plate are easier to bend. The 6 series and 7 series aluminum plates are too high in hardness and need to be annealed to the O state before bending work.

2. The Thickness of the Aluminum Plate

Like other materials, the thicker the aluminum plate, the less likely it is to bend. Therefore, when choosing, we can consider selecting aluminum plate to process the product to avoid breakage.

3. Bending Angle and Aluminum Plate Texture

No matter what the bending angle of the object is, the success rate will be higher. Therefore, when the aluminum plate is processed, the bending angle is as large as possible. For aluminum plate texture, bending direction should be perpendicular to the direction of aluminum plate texture, can not be parallel.

How to Judge the Quality of Aluminum Plate

1. The Chemical Composition of Aluminum Plate

The content of various alloying elements in the aluminum plate plays a vital role in the performance of the aluminum plate. If the increase or decrease of the content will affect the mechanical properties of the aluminum plate, So the content of the chemical composition of the aluminum plate is a standard for the quality of the aluminum plate.

2. Dimensional Tolerance of Aluminum Plate

As for Dimensional Tolerance of Aluminum Plates, We mainly consider these aspects, thickness, length and width, diagonal and flatness. If the aluminum plate does not meet the standard, it will affect the yield of the products produced by the enterprise during the production process.

3. Mechanical Properties of Aluminum Plate

The mechanical properties of aluminum plates include tensile strength, yield strength, elongation, hardness, etc. These indicators are something we need to pay attention to. If not properly controlled, it will also affect the subsequent processing of customer products.

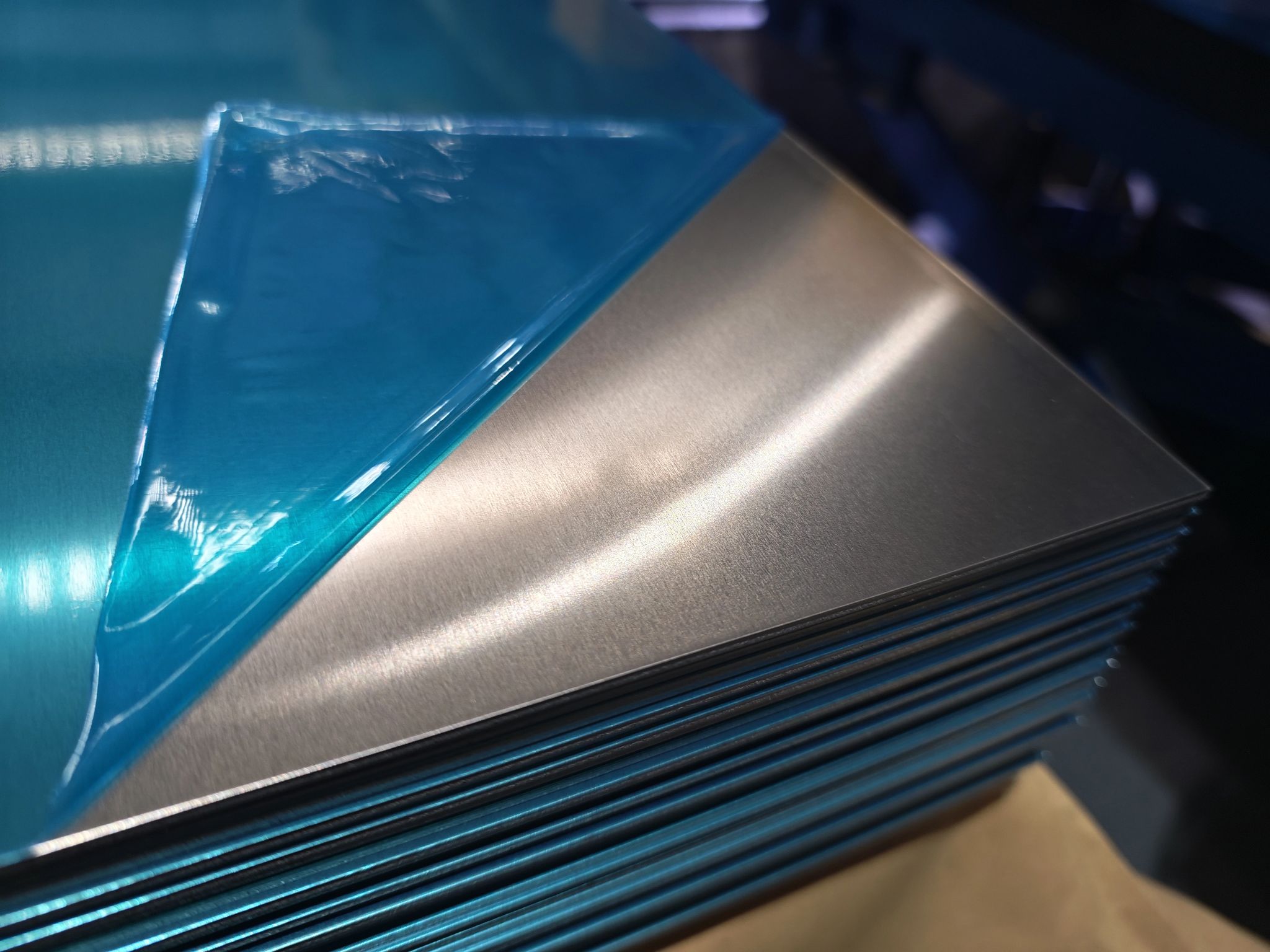

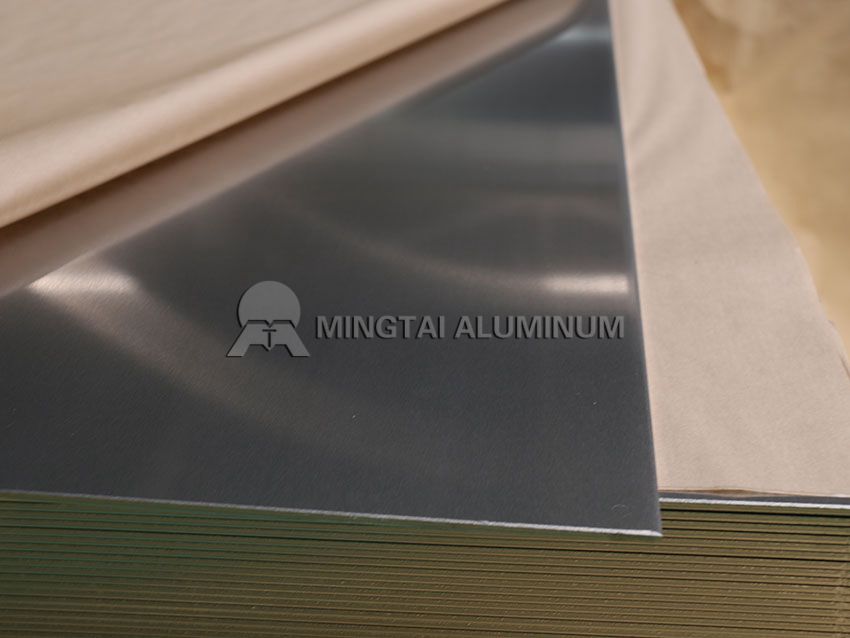

4.Surface Quality of Aluminum Plate

After the aluminum plate is finished, if the protective measures are taken improperly, it is easy to cause stains, scratches, scuffing, etc. on the aluminum plate, and also cause emulsion marks and yellow spots due to pollution. These surface quality problems are not conducive to the processing of the enterprise products. Not only is the surface not beautiful, it will affect the use of the product, so the company must pay attention to the selection of aluminum products.