High-quality 5083 Aluminium Welding Property by Mingtai

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

5083 Aluminium Welding Property

5083 aluminum plate is a high magnesium alloy. 5083 aluminum machinability is manifested in its conditional yield strength 0.2 (MPa)≥110, elongationδ10(%)≥20, and elongationδ5(%)≥12. 5083 aluminum plate has good strength, machinability, and high corrosion resistance in non-heat-treatable alloys. The most worth mentioning is the 5083 aluminium welding property, which makes it widely used in applications that require high plasticity and good weldability, such as automotive roof / bottom shields, flange materials, GIS shells, and so on. Next, Mingtai analyzes the 5083 aluminium welding property for you, so that you can make full use of the 5083 aluminum plate in practical applications.

Analysis of 5083 Aluminium Welding Property

(1) 5083 aluminum plate belongs to the Al-Mg series alloy. According to the analysis of the chemical composition of 5083 aluminium alloy, it can be known that due to the higher content of Mn, the 5083 aluminum machinability is improved without reducing the corrosion resistance of 5083 aluminium alloy, and it also improves 5083 aluminium welding. The added Mn element can make the phase distribution of Mg element uniform, and improve the strength and corrosion resistance. Due to the strong chemical reactivity of 5083 aluminium alloy, it is easy to form an oxide film on the surface, and most of them are refractory substances. Therefore, defects such as slag inclusion are prone to occur during 5083 aluminium welding.

(2) In fact, the thermal conductivity of 5083 aluminum plate is large (about 4 times that of steel), so 5083 aluminium welding is prone to cause non-fusion phenomenon.

(3) Since the thermal expansion coefficient of 5083 aluminium alloy is about twice that of steel, its modulus of elasticity is only 1/3 of that of steel. So, 5083 aluminium welding product are prone to generate large thermal stresses, resulting in deformation and cracks.

(4) Stomata are common defects in 5083 aluminium welding process. Hydrogen is the main cause of pores during welding of 5083 aluminium alloy. When 5083 aluminium welding, the source of hydrogen has two aspects: one is the moisture in the arc column atmosphere, and the other is the moisture absorbed by the welding wire and the oxide film on the surface of the 5083 aluminum plate. So, when welding Al-Mg alloys, the oxide film near the groove must be carefully removed before welding to keep the welding wire and 5083 aluminium alloy dry.

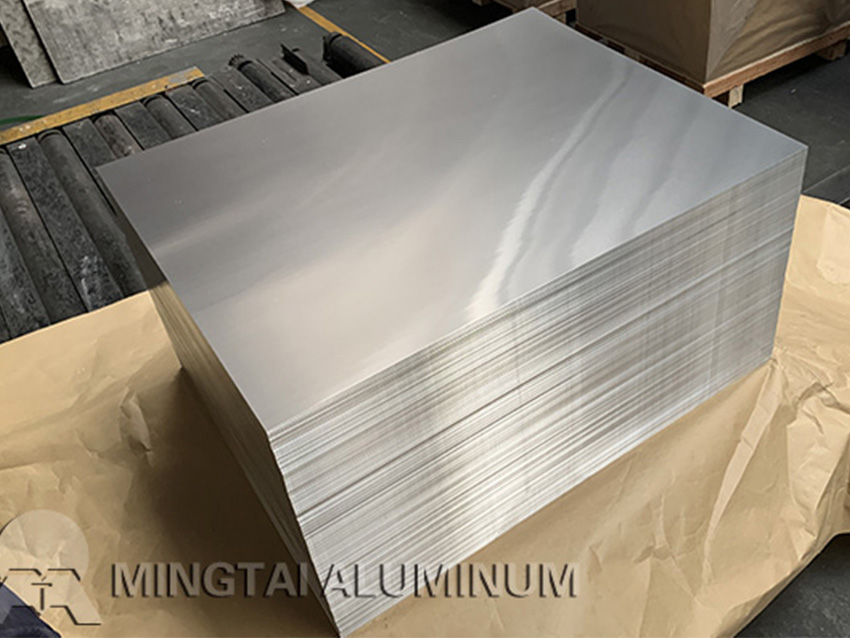

Mingtai high-quality 5083 Aluminium Welding Property

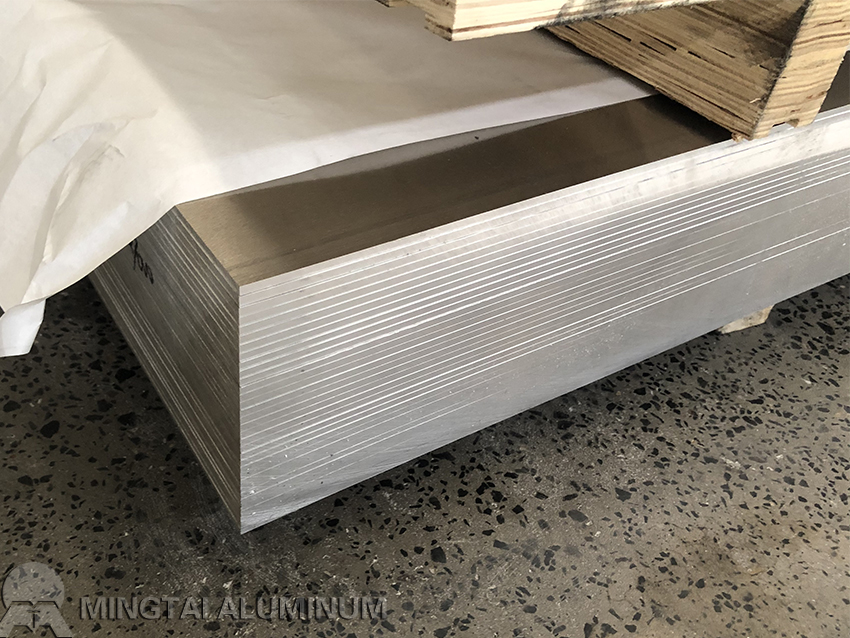

Henan Mingtai Aluminum Industry Co., Ltd is a large aluminium plate manufacturers and a listed company. 5083 aluminum plate is one of the outstanding products of Mingtai Aluminum. Mingtai strictly controls the product technology of 5083 aluminum plate. Through the determination of alloy composition, optimization of the casting process, homogenization heat treatment and rolling process test, products with high-quality 5083 aluminium welding property and other performance are produced to meet user requirements. Mingtai high-quality 5083 aluminium welding property is particularly prominent in the processing of complex parts such as marine aluminum plates, rail transit, automobiles, and molds. Not only that, Mingtai 5083 ultra-wide ultra-thick aluminum plate has internal stress relief and no deformation during cutting. The widest can reach 2650mm and the thickest can reach 500mm. It is a rare manufacturer in China that can produce ultra-wide and ultra-thick aluminum plates. There is a lot of information about 5083 aluminium alloy, Don’t hesitate to click the customer service dialog on the right, chat online, and get it for free!