The largest amount of 5083 alloy in Marine Grade Aluminum

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

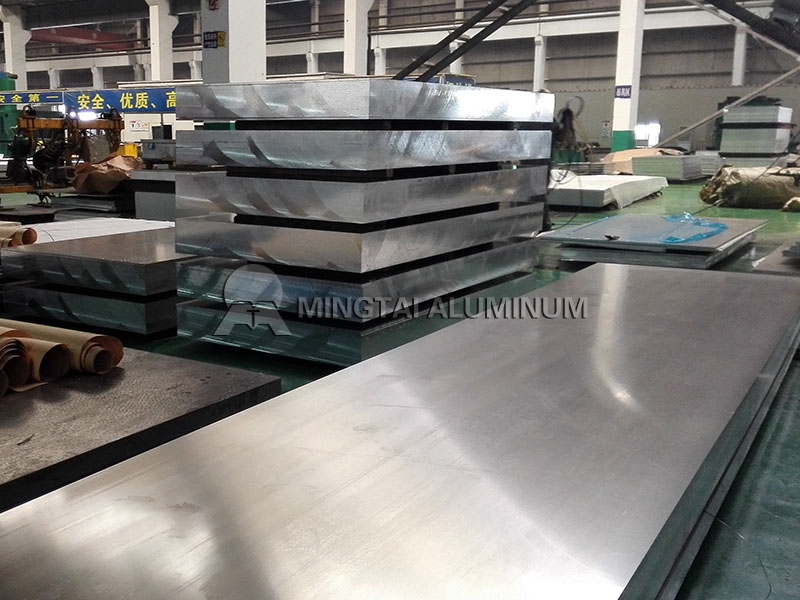

In the marine engineering ship manufacturing, the most used Marine Grade Aluminum is 5083 aluminum plate, which accounts for 55% of the total amount. The thickness of the plate is >4.5mm~170mm, and the 170mm thick plate is used to manufacture LNG (liquefied natural gas) transport ship. The “equator” part of the huge storage tank.

In addition to precise control of the composition of the alloy in production, special attention should be paid to the purification of the solution, because the Mg content of the alloy is high and easy to oxidize and absorb hydrogen. The ingot homogenization temperature is 455 ° C, the holding time is 32 h, and it can also be (460 ° C ~ 470 ° C) / (15 h ~ 20 h), the furnace temperature should be uniform, preferably up to ± 5 ° C.

5083 aluminum plate is a hard alloy. There are many hot rolling passes during hot rolling. The total processing rate of the first 5 passes is about 15%. When hot rolling on a single frame, the average processing rate of the last 5 passes should not exceed 25. %, when rolling on the (1+4) continuous rolling mill train, the rolling rate of the fourth finishing stand is not suitable to be >40% or 35%. Usually the hot rolled coil needs to be annealed before cold rolling. When cold rolling the strip, intermediate annealing is also performed. In the production of 5083-0 alloy strips, special attention should be paid to the control of the finished annealing process parameters. The furnace temperature must be uniform, and the strip or sheet should be in a completely recrystallized state, otherwise it will crack when subjected to subsequent bending. The temperature deviation in the furnace should be ≤5 °C, the charge should not be too much, the height of the plate is moderate, the temperature of the plate can reach 345 °C, and it can be kept for about 20 minutes if necessary. For the bent sheet, the tensile strength Rm and the yield strength Rpo.2 should be controlled to the lower limit of the standard value, and Rm is preferably not more than 300 N/mm2.