Marine grade aluminum 5083 aluminum plate status

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

What should be said here is the two states of the 5083 aluminum plate, which are the 5083-O state and the 5083h112 state. The state of the two is different, the processing technology is also different, and the price is also quite different.

The main alloying element in the 5083 alloy is magnesium, which has good corrosion resistance and weldability, as well as medium strength and excellent corrosion resistance. The 5083 aluminum plate is used as marine grade aluminum, which is widely used in marine applications such as ships, as well as automobiles and airplanes. Welded parts, subway light rails, pressure vessels that require strict fire protection (such as liquid tankers, refrigerated trucks, refrigerated containers), refrigeration units, television towers, drilling equipment, transportation equipment, missile parts, armor, etc.

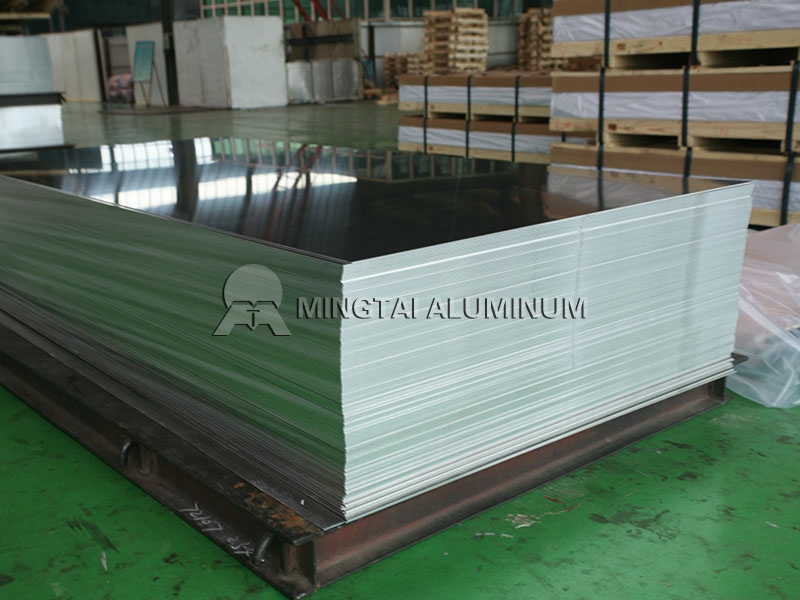

5083h112 aluminum plate

5083 aluminum plate status

1, F: free processing status

2, O: Annealed state

3, H: work hardening state

4, W: solution heat treatment state

5, T: heat treatment state

O: Annealed state Suitable for processed products that have been fully annealed to obtain the lowest strength

Hxxx status:

H111: It is suitable for products with the right amount of work hardening after final annealing, but the degree of work hardening is not as good as H11.

H112: Suitable for hot-formed products, the mechanical properties of this state have specified requirements.

H116: For products made of 5*** series alloys with magnesium content ≥4%. These products have specified mechanical properties and resistance to flaking corrosion.

The difference between 5083H111 and H112 in marine grade aluminum?

For the aluminum alloy, the standard is only the classification of different hardness after the different heat treatment of the prototype state, which has little to do with the main model.

So for the 5083 itself, there is no corresponding connection, here is just a description of the H state:

H-state subdivision

H followed by an Arabic number

H1 only indicates the work hardening state, and is suitable for products that have been subjected to work hardening without heat treatment to obtain the specified strength; H2 work hardening and incomplete annealing, suitable for work hardening beyond the specified requirements, but incomplete annealing and strength reduction To the specified product, for alloys that soften at room temperature.

The final minimum tensile strength of the H2 state is the same as that of the H3 state. For other alloys, the minimum tensile strength of the H2 state is the same as that of the H1 state, but the elongation is slightly higher.

H3 Work hardening and stabilization, suitable for products that have been subjected to low temperature heat treatment after work hardening or mechanical properties due to thermal effects during hot working. Stabilization usually improves ductility. This code is only suitable for aging softening at room temperature. alloy.

HX1 (X stands for 1, 2, 3) followed by an Arabic number

The H1, H2 and H3 state codes are followed by an Arabic numeral indicating the degree of work hardening. The number 8 indicates the final tensile strength obtained after about 75% cold deformation (processing temperature not exceeding 50 °C) after complete annealing. The states and the states of the number 8 are indicated by the numbers 1-7, respectively. Where the final tensile strength is the intermediate value between the O state and the HX8 state, the number 4 is used (HX4); the final tensile strength is the O state and HX4. The intermediate value of the state is represented by the number 2 (HX2); when the final tensile strength is the intermediate value of the HX4 state and the HX8 state, it is represented by the number 6 (HX6). When the minimum tensile strength exceeds the HX8 state by at least 10 MPa. It is represented by the number 9 (HX9). When the number connected after the HX code is an odd number, it indicates that the intensity is the arithmetic mean of the adjacent two even states.

When some metals cannot reach the minimum tensile strength of HX8 state by cold deformation (complete annealing and 75% cold deformation), the HX6 state can be determined by about 55% cold deformation or HX4 state can be determined with about 35% cold deformation. HXX Code followed by Arabic numerals.