Advantages of 6061 aluminum plate for mold manufacturing

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

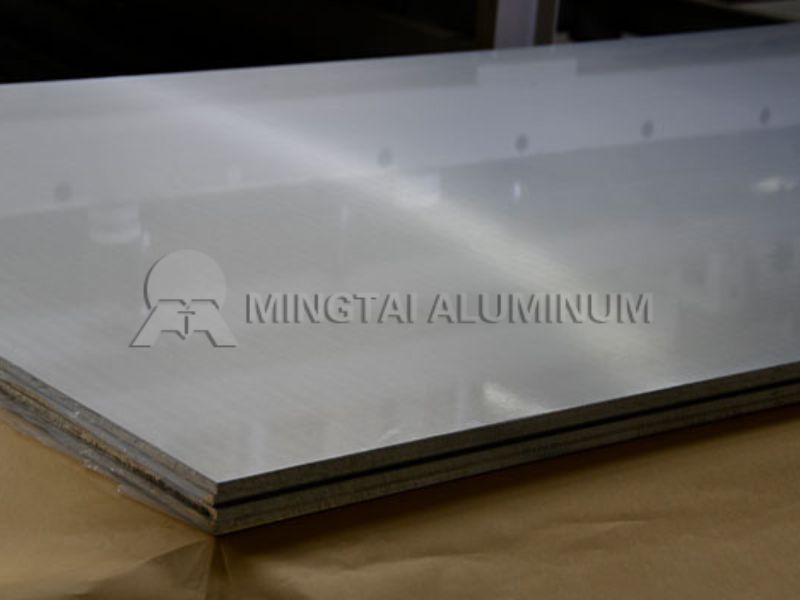

A mold is a tool used in industrial production to make molded items, which transforms the blank into a specific shape and size through external force. Molds are precision tools with complex shapes that withstand the expansion force of billets. They have high requirements for structural strength, stiffness, surface hardness, surface roughness, and machining accuracy. The raw materials for aluminum alloy molds are generally 5 series, 6 series, and 7 series medium thick aluminum plates.

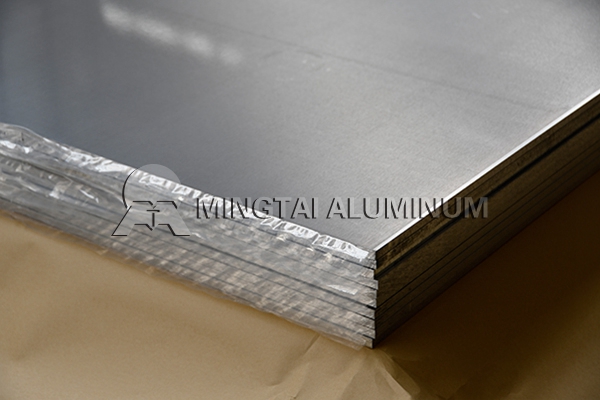

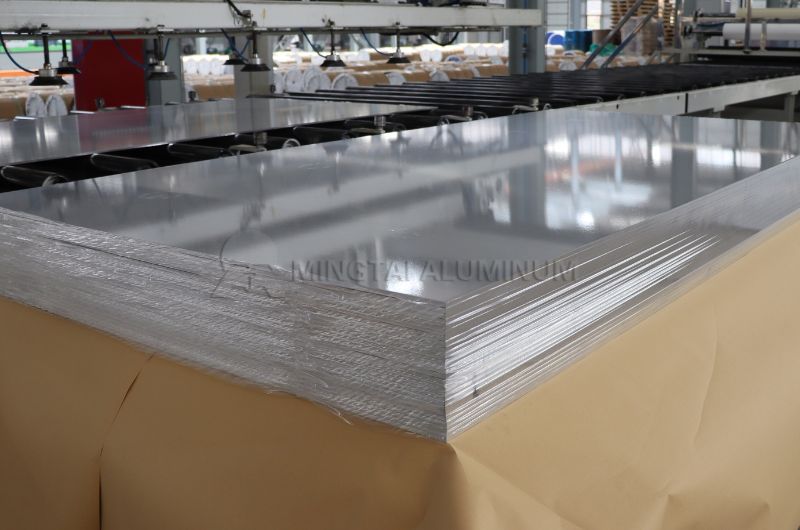

6061 aluminum plate is commonly used to manufacture industrial molds. Its main alloying elements are magnesium and silicon, which have the characteristics of moderate strength, good corrosion resistance, weldability, good oxidation effect, and good processability, wear resistance, and durability. It is very popular in the field of mold manufacturing.

Technical parameters of 6061 aluminum plate

| Temper | F,O,T4,T6,T651,H112 |

| Thickness(mm) | 0.3-500 |

| Width(mm) | 100-2800 |

| Length(mm) | 500-16000 |

| Application | Mobile phone slots, phone cases, molds, cars, mask machines, precision machining, etc |

Five Advantages of 6061 Aluminum plate for Mold Manufacturing

Improve mold production efficiency

Aluminum alloy has good thermal conductivity, can be heated or cooled more effectively, and the demolding time is shortened.

Shorten production time

Aluminum alloy has excellent processing performance and can be cut at high speed.

Improve corrosion resistance

6061 aluminum plate keep the surface of the mold bright and clean, and extend the service life of the mold.

Improve polishing quality and efficiency

Aluminum alloy has high strength and stability, making polishing easier and achieving a mirror effect quickly.

Reduce costs and increase efficiency

Meanwhile, due to the lightweight and excellent processing performance of aluminum alloy materials, it can greatly reduce the wear of machines and tools, reduce downtime and maintenance time, and extend the service life of machinery. The use of aluminum alloy molds can reduce energy consumption and labor intensity of workers, which is beneficial for improving the operating environment.