Advantages of Honeycomb Sheet

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

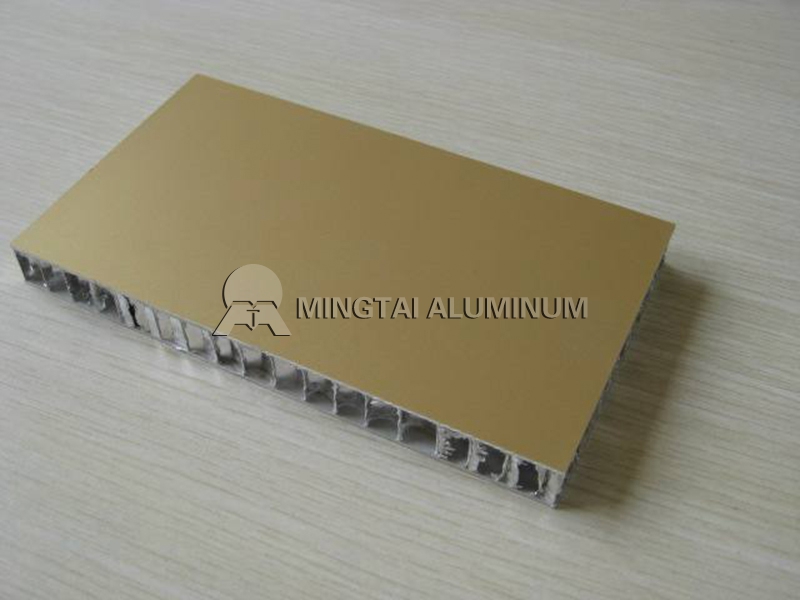

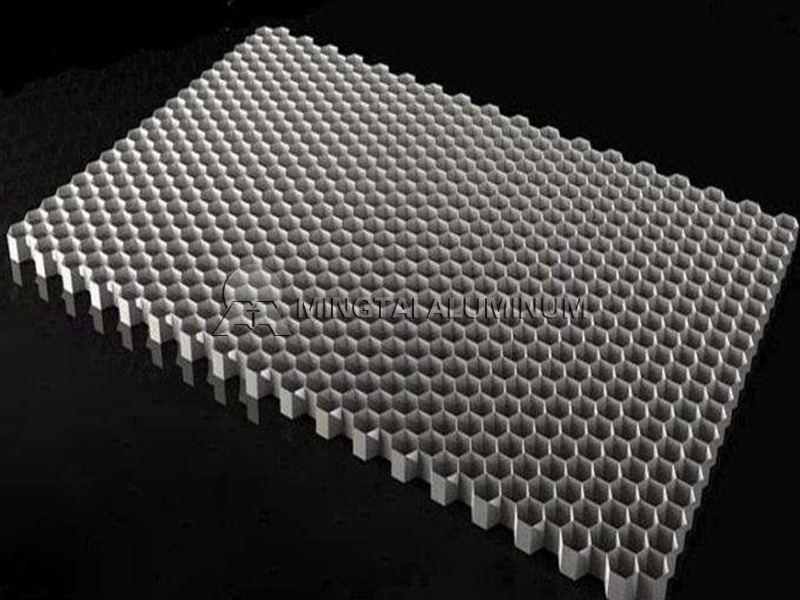

The aluminum honeycomb sheet is a sheet made of two aluminum sheets firmly bonded to both sides of a thick honeycomb core material. It suitable for civil buildings, car and boat decoration, etc.

Advantages of Honeycomb Sheet

Heat Insulation

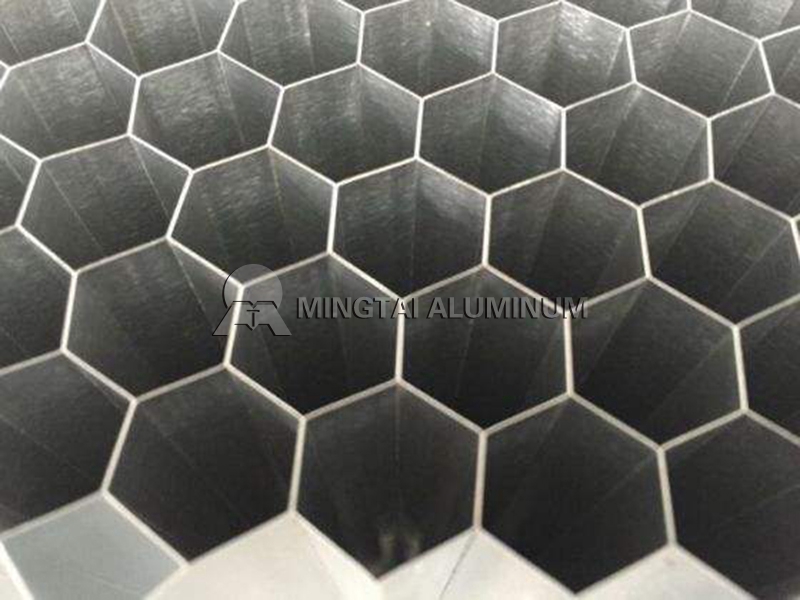

The core material is a honeycomb core made of hexagonal 3003 aluminum foil, and the front and back skins are formed by roll forming technology. The melting point of aluminum is as high as 660 ° C, so when the fire occurs, neither the surface aluminum sheet nor the middle aluminum honeycomb core will burn.

Corrosion Resistance

The surface of the aluminum honeycomb sheet is highly resistant to corrosion after being treated with a highly resistant fluorocarbon resin. It is sprayed by salt spray (simulating the damage caused by the climate around the ocean) for 48 hours without pinholes, cracks, and blistering. It can be widely used in the decoration of curtain walls, roofs, large facade signs and interior walls of buildings.

Bearing Capacity

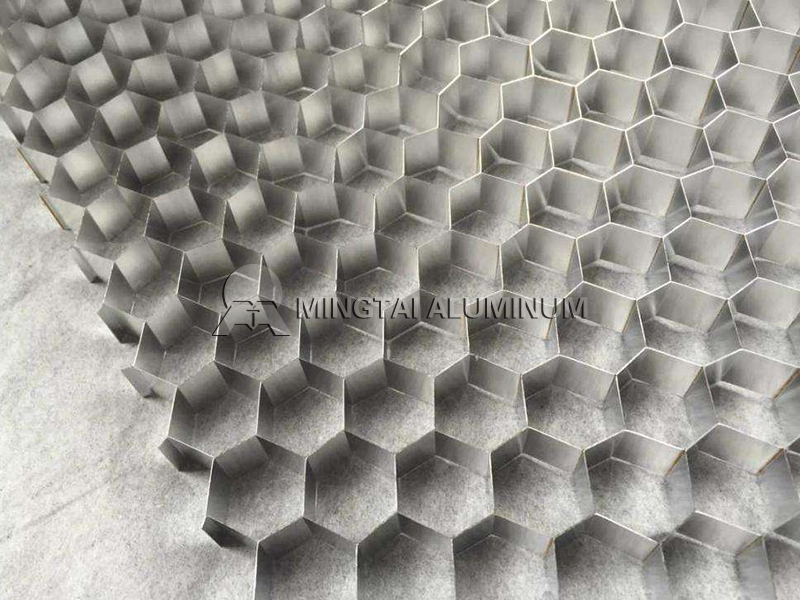

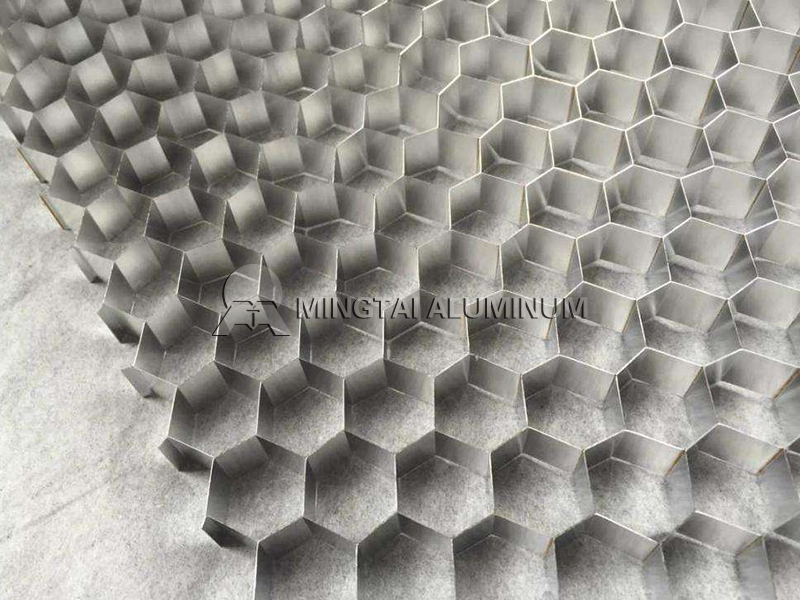

The aluminum honeycomb sheet has a high strength bearing capacity thanks to the scientific design of the aluminum honeycomb core. The aluminum honeycomb sheet has high-strength aluminum sheets on both sides, and the inner layer is a special hexagonal aluminum honeycomb core. It is made of 3003 aluninum foil with high hardness. It is used as a honeycomb core board adhered to the sandwich structure. These mutually confined dense honeycomb cores are like many small I-beams, which can disperse the pressure from the direction of the board, so that the board is stressed evenly, which ensures that the board can maintain a high degree of flatness even in a large area.

Sound-absorbing Performance

Since the honeycomb core in the aluminum honeycomb sheet is divided into a plurality of closed cells, the air flow is prevented, so that when the sound wave encounters a wall or other obstacle, some of the sound energy is reflected. And because of converted into heat energy ,some is absorbed by walls or obstacles . And a small amount is transmitted to the other side.

Environmental Protection

Aluminum honeycomb foil is a pure aluminum product. It doesn’t contain harmful substances to the human body, and doesn’t evaporate the gas that is harmful to human body. It is non-radioactive so that can be completely recycled. It is also an environmentally friendly product for the current development of green sheets.

Diverse Colors

Aluminum honeycomb sheet has a variety of coatings and a wide range of colors. On a solid color basis, the color selection can be processed into more colors, such as metallic color, imitation wood color, stone color, etc. The shape is more luxurious and beautiful, and it caters to the public and personal preferences. Aluminum honeycomb sheet is generally made of fluorocarbon roll-coated aluminum sheets for panels, 3003 aluminum foil, and 5052 aluminum foil are used for honeycomb cores. The most important point of the fluorocarbon roll-coated aluminum sheet is the continuous roll coating process. The aluminum sheet is painted in one time, ensuring that the product has no color difference, good coating smoothness and reliable quality. At the same time, the exterior wall of the building can be kept bright for a long time. After long-term sun and rain or industrial waste gas pollution, it is obvious that the roller-coated board is brighter than the sprayed board, and has good adhesion and weather resistance. It is recognized as the first-class material by the world’s builders.