Aluminium Foil for Blister Packaging

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Aluminium Foil for Blister Packaging

Aluminium blister foil is a kind of aluminium foil for pharmaceutical packaging. Such as 8021-O aluminium foil for blister packaging (cold forming), 8011-H18, 8011-O grade pharma foil for PTP, 8011-H14/ 8011-H16 for medicine vial seals, and 8079 tropical blister foil, etc. For the common thickness is 0.016-0.5mm. Here, Mingtai Al., produces pharmaceutical foil with wettability A grade, prime quality, superior performance, and very competitive price ! Welcome to consult us !

Pharmaceutical Foil Alloy 8011 8021 8079

8021 O Pharmaceutical Foil

Alloy Element Proportion

| Alloy Grade | Fe | Si | Cu | Mn | Mg | Zn | Ti | Others | Al |

| 8021 | 0.5-1 | 0.4-0.8 | 0.1 | 0.1 | 0.1 | 0.1 | 0.05 | ≦0.05 | Balance |

Features : In fact, 8021-O aluminium blister foil shows better corrosion resistance and ductility. For example, for the yield strength of 8021-O aluminium blister foil is 85-105 MPa (KSI). and the min elongation is 13%.

Typical Application: In generally, 8021 aluminum foil is often used for high-end and highly sealed, moisture-proof and light-shading pharma packaging, such as cold forming aluminium blister film for pharmaceutical products, etc

Alloy 8011 Medicine Aluminum Foil

Alloy Element Proportion

| Alloy Grade | Fe | Si | Mn | Cu | Mg | Cr | Zn | Ti | Each | Total | Al |

| 8011 | 0.6~1 | 0.5~0.9 | ≦0.2 | ≦0.1 | ≦0.05 | ≦0.05 | ≦0.1 | ≦0.08 | ≦0.05 | ≦0.15 | Balance |

Features : Such as popular 8011-H18 aluminum foil and 8011-O aluminium foil for blister packaging has high cup convex value, high heat sealing strength, no pinhole, good airtight shading and so on. It can be ideally applied to the PTP packaging such as capsule alu alu panel. Beside, the min UTS of 8011 HO aluminium blister foil is 85 MPa, and the min elongation is 1%. In addition, for the min UTS of 8011 h18 is 175(MPa), and the min elongation is 2%.

Typical Application: 8011 medicine aluminum foil is widely used for both blister foil and strip foil, PTP (PressThrough Packaging), alu alu foil, etc. In addition, such as 8011-H14/ 8011-H16 medicine aluminum foil is also the ideal material for medicine bottle caps of oral liquid, antibiotic, injection vial seals, etc.

8079 Tropical Blister Foil

Alloy Element Proportion

| Alloy Grade | Fe | Si | Cu | Zn | Others | Al |

| 8079 | 0.70 – 1.3 | 0.05 – 0.3 | ≤ 0.05 | ≤ 0.1 | ≤ 0.15 | Balance |

Features : 8079-O aluminum foil is common aluminium blister foil with excellent moistureproof, shading and high barrier ability, non-toxic, tasteless, etc. Beside, the tensile strength of 8079-O aluminum foil is 55-110 MPa, and the min elongation is 4%.

Typical Application: In fact, 8079 blister foil is perfect material for tropical-type blister packaging. For the tropical blister packaging is refers to adding a layer of cold stamping aluminum foil outer cover on the outside of the hot forming plastic bubble cover and PTP aluminum foil. It is the highest end of a kind of packaging aluminum foil in pharma packaging.

Pharmaceutical Aluminum Foil Technical Parameters

| Usage | Typical Alloy | Temper | Thinkness(mm) | Widthness(mm) | Typical Product |

| PTP Medicine Foil | 8011 aluminum foil | H18 | 0.016-0.5 | 200-1600 | Tablet &Capsule blister pack,etc |

| Blister Foil | 8021 aluminum foil | O | 0.04-0.065 | 200-1600 | Cold-formed blister packing,etc |

| Tropical Blister Foil | 8021/ 8079 aluminum foil | O | 0.016-0.2 | 300-1050 | Tropical blister packaging,etc |

| Medicine Bottle Cap Foil | 8011 aluminum foil | H14, H16 | 0.016-0.5 | 200-1800 | Oral liquid、Injection vial seals,etc |

| Medical Aluminum Foil Seals | 1060 aluminum foil | O, H18 | 0.014-0.2 | 200-1600 | Medical aluminum foil seals,etc |

Advantages of Mingtai Pharmaceutical Aluminum Foil

1.Most importantly, the pattern of Mingtai aluminium blister foil is flat. and the brush water must reach Class A.

2.In addition, the Mingtai pharma foil surface requirements are very strict, dark surface is bright, no black oil spots, scratches, small black wires, bright lines, roll marks, convex-concave point, pinholes, holes, or mosquitoes .

3.Besides, the thickness must be strictly in accordance with the card.

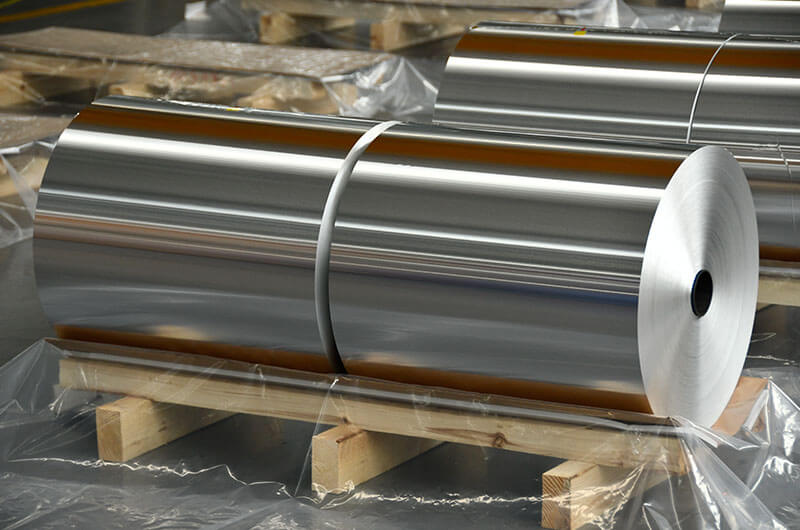

4.What’s more, our transport packaging of aluminum blister foil is moisture protection, avoid oxidation and iron core also avoid oxidation