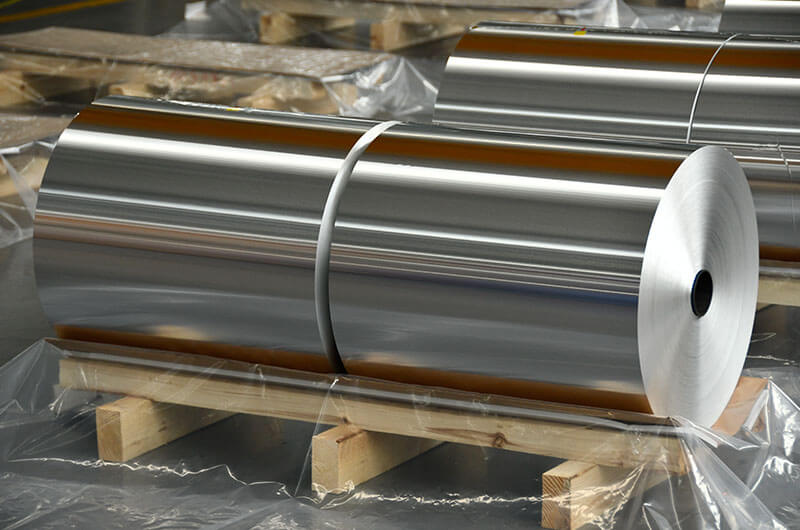

Aluminum foil for sale

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Aluminum foil manufacturer introduces aluminum foil:

A hot stamping material which is directly calendered into a sheet by metal aluminum, and its hot stamping effect is similar to that of pure silver foil stamping, so it is also called a fake silver foil. Since aluminum has a soft texture and good ductility, it has a silvery white luster. If the calendered sheet is smashed on an offset paper with a material such as sodium silicate, an aluminum foil sheet can be formed. However, the Aluminum foil itself is easily oxidized and the color is darkened, and friction, touch, and the like are discolored, so it is not suitable for hot stamping of a book cover that has been preserved for a long time.

Aluminum foil classification:

thickness:

Aluminum foil can be divided into thick foil, single zero foil and double zero foil according to thickness difference.

1 thick foil (“heavy gaugefoil”): a foil having a thickness of 0.1 to 0.2 mm.

2 “medium gauge foil”: a foil having a thickness of 0.01 mm and less than 0.1 mm/.

3 “light gauge foil”: The so-called double-zero foil is a foil with two zeros after the decimal point in its thickness, usually aluminum foil with a thickness less than 0.01, ie 0.005~0.009mm aluminum foil . In foreign countries, an aluminum foil having a thickness of ≤ 40 ltm is sometimes referred to as a “light gauge foil”, and an aluminum foil having a thickness of > 40 btm is collectively referred to as a “heavy gauge foil”.

Shape:

Aluminum foil can be divided into rolled aluminum foil and sheet aluminum foil according to the shape. Aluminium foil deep processing wool is mostly supplied in rolls, and only a few handicraft packaging applications use sheet aluminum foil.

Aluminum foil can be classified into hard foil, semi-hard foil and soft foil according to the state.

1 Hard foil: Aluminum foil that has not been softened (annealed) after rolling. When it is not degreased, the surface is ruined. Therefore, the hard foil must be degreased before printing, lamination, coating, and can be used directly if it is used for forming.

2 Semi-hard foil: Aluminum foil hardness (or strength) between the hard foil and the soft foil, usually used for forming.

3 Soft foil: Aluminum foil which is softened after being fully annealed after rolling. The material is soft and has no residual oil on the surface. Soft foils are used in most applications, such as packaging, composites, and electrical materials.

surface condition

The aluminum foil can be divided into a light aluminum foil and a double-sided aluminum foil according to the surface state.

1 single-sided aluminum foil: double-rolled aluminum foil, after the split, one side is bright, and the surface is black. Such aluminum foil is called a light aluminum foil. The thickness of a side of a light aluminum foil usually does not exceed 0.025 mm.

2 double-sided aluminum foil: single-rolled aluminum foil, the two sides are in contact with the rolls. The two sides of the aluminum foil are divided into mirror two-sided aluminum foil and ordinary two-sided aluminum foil due to the different surface roughness of the rolls. The thickness of the two-sided aluminum foil is generally not less than 0.01 mm.

Processing status:

Aluminum foil can be divided into plain foil, embossed foil, composite foil, coated foil, colored aluminum foil and printed aluminum foil according to the processing state.

1 plain foil: Aluminum foil, also called light foil, without any other processing after rolling.

2 embossed foil: aluminum foil with various patterns on the surface.

3 composite foil: a composite aluminum foil formed by laminating aluminum foil and paper, plastic film and cardboard.

4 coated foil: aluminum foil coated with various types of resin or lacquer on the surface.

5 color aluminum foil: the surface is coated with a single color of the aluminum foil. 6 Printing aluminum foil: Aluminum foil which is formed by printing various patterns, patterns, characters or pictures on the surface, which can be one color, up to 12 colors.

The soft aluminum foil can be further pressed into a four-zero foil for high-end decoration.

Aluminum foil features:

The aluminum foil has a clean, hygienic and shiny appearance. It can be integrated with many other packaging materials, and the surface of the aluminum foil is better than other materials. In addition, the aluminum foil has the following characteristics:

(1) The surface of the Aluminum foil is extremely clean and hygienic, and no bacteria or microorganisms can grow on its surface.

(2) Food foil is a non-toxic packaging material that can be in direct contact with food without any concern that may endanger human health.

(3) Aluminum foil is an odorless and odorless packaging material that does not impart any odor to the packaged food.

(4) If the aluminum foil itself is not volatile, it itself and the packaged food will never dry or shrink.

(5) There is no oil penetration of the aluminum foil at high temperatures or at low temperatures.

(6) Aluminum foil is an opaque packaging material, so it is a good packaging material for products exposed to sunlight, such as margarine.

(7) Aluminum foil has good plasticity, so it can be used to package products of various shapes. It can also be used to create containers of various shapes.

(8) Aluminum foil has a large hardness and a large tensile strength, but its tear strength is small, so it is easily torn.

(9) The aluminum foil itself cannot be heat-sealed and must be coated with a heat-sensitive material such as pe to be heat-sealed.

(10) When aluminum foil is in contact with other heavy metals or heavy metals, there may be adverse reactions.