Aluminum plate manufacturers explain the reasons for aluminum plate cracking

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Aluminum plate is a kind of material used in life. When people bend the aluminum plate at 90 degrees, crack phenomenon will occur, which will seriously affect the performance and plague the users. So what is the cause of the crack in the aluminum plate? How to avoid it? Mingtai Aluminum plate manufacturers answer everyone one by one.

Analysis of the causes of bending and cracking of aluminum sheets:

1. The hardness of the aluminum plate is too high. The hardness of the aluminum plates of different grades and states is different. Generally, the aluminum plates of the 1 series, 3 series and 5 series are easy to be bent, and the hardness of the 6 series and 7 series aluminum plates is too high, and it is necessary to first perform annealing treatment to the O state before bending.

2. The state of the aluminum plate. The state of the aluminum plate is divided into full hard, semi-hard, soft state (also called O state), and the hard bending effect is basically not very good (the aluminum plate state is H18, H19, H38, etc. are all hard), semi-hard state Almost all aluminum panels can be bent (H24 is semi-rigid). The O-state bend is certainly no problem, but because it is too soft, basically this kind of state is used to bend less.

3. The quality of the aluminum plate. If the aluminum plate manufacturers are producing aluminum plates, the production process is not mature, the processed aluminum plate impurities alloy is exceeded, and the chemical composition is unqualified, which will also cause cracking when the aluminum plate is bent. There is also the quality of the aluminum plate, the same type of aluminum plate, the aluminum plate produced by the large aluminum plate manufacturers is generally not easy to crack, and the products produced have quality assurance.

4. The bending process is improper. The side of the 1 bend is parallel to the rolling direction of the aluminum plate, so that it is easy to crack and turn the bending direction by 90 degrees. 2 The bending of the aluminum plate is greater than the minimum bending radius, and the bending radius is generally 1.5 times the thickness of the plate. 3 The thickness of the sheet is too thick and the bending angle exceeds the bending limit of the material itself.

Introduction to measures to avoid bending and cracking of aluminum sheets:

If you want to avoid serious cracking when the aluminum plate is bent, you must first choose a large, regular aluminum plate manufacturer, so that the quality of the aluminum plate is more guaranteed. Secondly, confirm the strength and elongation of the aluminum plate before bending to see if it is suitable for bending. Finally, pay attention to the correct way when bending.

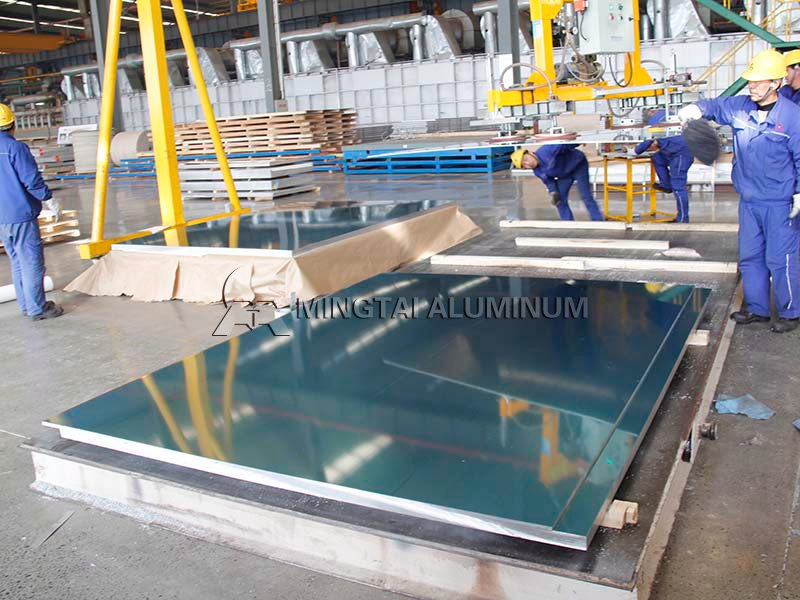

Mingtai Aluminum plate manufacturers:

Mingtai Aluminum has 20 years of experience in aluminum sheet processing, specializing in the supply of 1-8 series aluminum alloy sheets, and the processing technology is mature. The company has a good reputation in the industry with high quality products and professional after-sales service.