Application and characteristics of 3003, 3004, 3005 aluminum coil

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

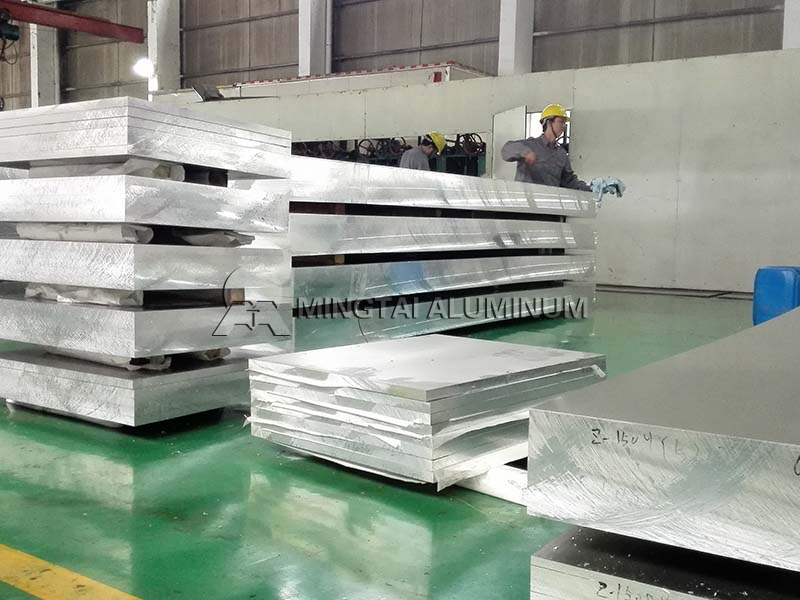

3003 aluminum coil plate is commonly used in the manufacture of new energy vehicle power battery casings. The development of new energy vehicles is very rapid. At present, China has surpassed the United States to become the world’s largest new energy vehicle market.

This is due to the policy promotion of the central and local governments, as well as the transformation of car owners’ consumption concepts and the efforts of automobile companies. The fiery heat of the new energy vehicle market has directly affected the development of the power battery industry. Under such opportunities, the development of power battery companies that provide power sources for new energy vehicles has grown by leaps and bounds.

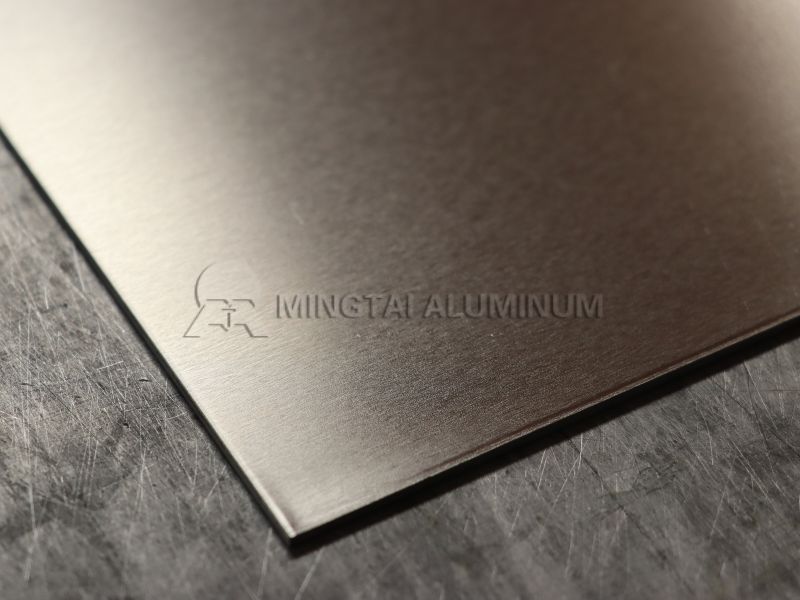

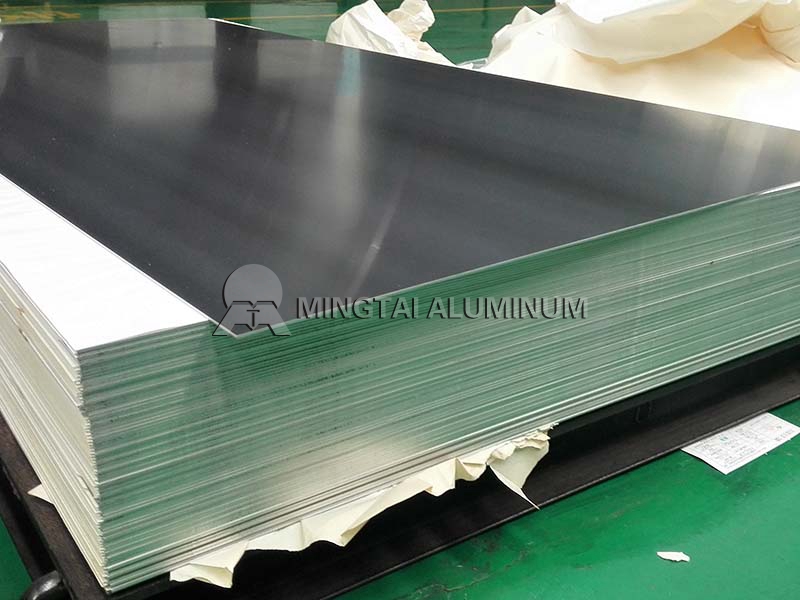

The 3003 alloy aluminum plate produced by Mingtai Aluminum has good formability, and is mainly used for deep-drawing materials. The use of 3003 aluminum alloy products for stamping parts, models, shells, etc. has many advantages such as good surface, good plasticity and pressure resistance.

The power battery case made of 3003 aluminum alloy product has impact resistance, non-breaking and leakage, and can meet the requirements of strength and rigidity of the power battery casing, and the aluminum alloy has low density and light weight, can reduce the weight of the battery, and improve the battery capacity density. Stabilize the battery operation, indirectly reduce the quality of the vehicle and increase the vehicle’s endurance. 3003 aluminum coil is the best choice for new energy vehicle power battery casing.

3004 aluminum sheet is often used in cans, requiring parts with higher strength than 3003 alloy, chemical production and storage devices, sheet metal parts, building parts, construction tools, and various lamp parts.

The reason why the application of 3004 aluminum plate is so wide is that it has been consistently recognized by the market because of its stable performance, high strength, oxidation, coloring, stamping resistance, high elongation strength, and difficulty in cracking.

Because the price is lower than the price of the 5 series products, the market acceptance is higher. The strength of the 3005 aluminum plate is about 20% higher than that of 3003, and the corrosion resistance is also better. The 3005 aluminum sheet has good formability, weldability, and corrosion resistance.

The 3004 aluminum coil is used to process parts that require good formability, high corrosion resistance, or require both these properties and work with higher strength than 1XXX alloys, such as kitchen utensils, food, and Chemical product processing and storage devices, tanks and tanks for transporting liquid products, various pressure vessels and pipes for processing of thin plates, general radiators, heat sinks, cosmetic plates, photocopier drums, marine materials