Automotive aluminum | Aluminum for automotive engine wheels

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

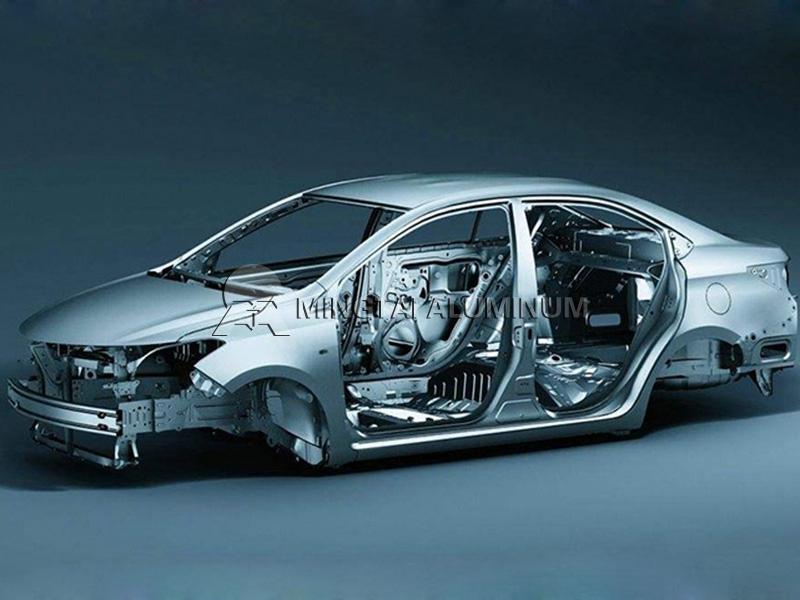

Application of aluminum alloy in the automotive industry:

First of all, in this era of car pursuit of lightweight, even if you can lose one kilogram, manufacturers are willing to do, many car manufacturers through the car body, engine, wheels to make cars lose weight. Automotive aluminum materials have good strength, resistance The advantages of good etch performance, good processing performance and easy regeneration are widely used in vehicle body manufacturing.

5754 aluminum plate for automotive engines:

The all-aluminum engine can reduce the weight of the vehicle by 10 to 20 kg compared to the cast iron engine.

Secondly, the all-aluminum engine has good heat dissipation and strong anti-explosion. Good heat dissipation means that the oil rises quickly during the starting process of the vehicle, the wear on the cylinder is small, and the vehicle can enter the working state faster. The good anti-explosion means that the vehicle can use lower-grade fuel to save the owner. Part of the expenses.

The engine aluminum can be 5754 aluminum alloy plate, and the 5754 aluminum sheet has medium strength, excellent processing performance, good corrosion resistance, weldability and easy processing. The 5754 aluminum alloy plate in different heat treatment conditions is automobile manufacturing (sedans). Main materials used in the door, mold, seals, and canning industry.

5754 aluminum plate is also widely used in welding structures, storage tanks, pressure vessels, ship structures and offshore facilities, transportation tanks. In addition, there are many domestic alloys used in high-speed rails, which are often used to make high-speed rail noise barriers. Structural parts such as internal sheet metal welding.

6061 aluminum plate for automotive wheels:

The wheel hub is divided into two categories: steel wheel hub and alloy wheel hub. The steel wheel hub has poor heat dissipation performance, heavy weight and easy rust. The aluminum alloy is light in weight and has good heat dissipation performance, which can better reduce the weight of the vehicle body. Therefore, the aluminum alloy wheel wheel gradually replaces it. The application of steel wheels.

Aluminum alloy wheels have won the favor of more and more car manufacturers because of their beautiful appearance, safety and comfort. Nowadays, almost all new models use aluminum alloy wheels, and many car owners have replaced the original wheels for aluminum alloy wheels.

Alloy wheels are mostly made of aluminum as a basic material, and metal elements such as manganese, magnesium, chromium and titanium are appropriately added. Compared with steel wheels, alloy wheels are energy-saving, safe and comfortable, so more and more cars have already listed alloy wheels as standard.

Mingtai Aluminum has a 6061 aluminum alloy plate for the production of wheels. The state is O-state, the thickness is 5.5-7.5mm, and the width is 1220mm. The 6061 aluminum plate of this wheel is different from the ordinary 6061 aluminum plate because the wheel is driving. The process requires long-term wear and tear, so the fatigue resistance of aluminum is very high. Therefore, the aluminum for the 6061 wheel hub produced by Mingtai is a soaking aluminum ingot. The temperature control of hot rolling is strict, including cold rolling and annealing. They are all produced strictly in accordance with the special aluminum for the wheel hub.

After the customer takes the aluminum plate, the aluminum plate is made into an aluminum cylinder, which is then welded and then spin-formed into the shape of the hub. After quenching and aging treatment, the strength of the 6061T6 aluminum alloy is achieved, and a key process is testing. The wear resistance of the hub is generally in the number of turns. The normal standard should reach 300,000 rpm. The hub is not pierced or cracked.