Cable foil

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Introduction to Cable foil:

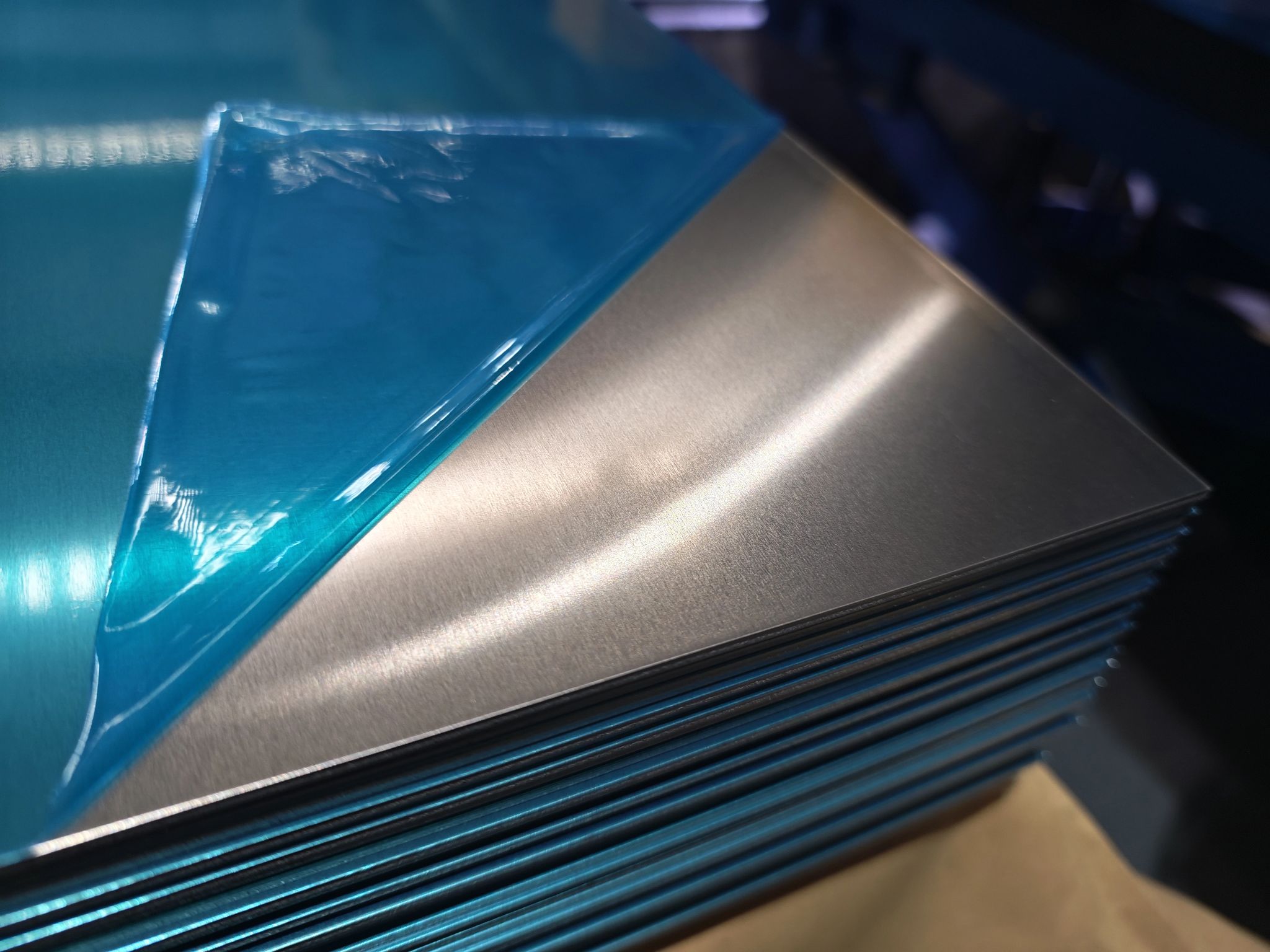

The cable foil is an aluminum-plastic composite foil which is formed by applying a film on one or both sides by using the sealing property and shielding property of the aluminum foil, and is used as a shield for the cable. Cable foil requires less oil on the surface, no holes, high mechanical properties, and low overall quality requirements, but the length requirements are extremely strict.

Cable foil production process:

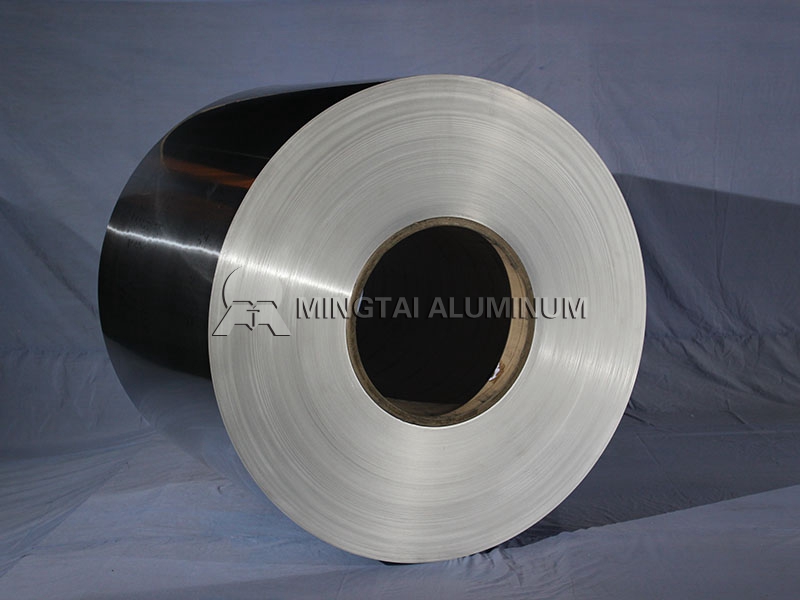

The cable foils 1235 and 8011 produced by Mingtai are mainly in O state. The product quality is high and the performance is stable. It is well received by the market. After continuous casting, rolling, cold rolling, slitting and complete annealing, it is divided into the length required by users. The small coil supply cable foil composite factory is covered with a plastic film on the surface and cut into several strips into a coiled cable supply cable factory.

Cable foil has high requirements on length and strength:

In general, the overall quality requirements of the foil foil for the aluminum foil material are not very high, only the surface with less oil, no holes can be. Because the surface quality of aluminum foil is the most important factor affecting the peel strength, the main surface quality problems are oil spots, corrosion, peroxidation and so on. However, cable foils have higher requirements on length and mechanical properties.

In terms of length, the length requirement of the Cable foil is only allowed to be longer and not allowed to be short. This requires careful calculation of the billet when casting, and the billet should be kept as long as 10 or 12 times the length of the customer’s demand, plus an additional 3% error; in terms of mechanical properties, that is, strength, The standard for cable foils in the communications cable industry is not high, but most customers require Cable foil strengths greater than 70 MPa or 80 MPa. In this regard, Henan Mingtai Aluminum explained that the reason for customers to consider this is mainly to prevent cracking when laminating the film, especially when winding on the cable. Because the plastic film is cut into several strips, the narrowest is 12mm. There may be slight cracks or burrs when cutting. When using, it should be wrapped with tension. If there is a slight defect, it will break due to stress concentration. .

Cable foil mechanical properties:

| Alloy grade | Status | Thickness / mm | Tensile strength / Mpa | Elongation after break /% |

| 1235 | O | 0.025-0.03

0.03-0.06 |

70-80 | ≥4%

≥8% |

|

8011 |

O |

≤0.14 |

80-98 |

≥16 |

| ﹥0.14~0.19 | ≥20 | |||

| >0.19 | ≥23 |

Cable foil alloy composition:

| Ingredient | Si | Fe | Cu | Mn | Mg | Gr | Zn | Ti | Al |

| 1235 | 0.65Si+Fe | 0.05 | 0.05 | 0.05 | —— | 0.10 | 0.06 | 99.35 | |

| 8011 | 0.50-0.9 | 0.6-1.0 | 0.10 | 0.20 | 0.05 | 0.05 | 0.10 | 0.08 | margin |