Characteristics of 5052 Aluminum Coil Comprehensive Description

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

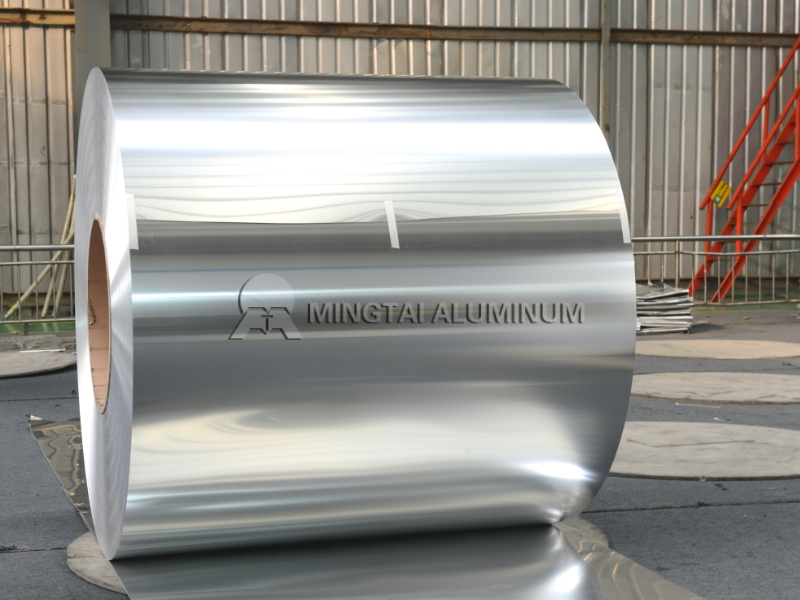

Characteristics of 5052 Aluminum Coil

5052 aluminum coil is a 5052 aluminum plate rolled into a roll. It can be cut into different widths of 5052 aluminum coil with different slitting machines to make up for the narrowest requirement that the 5052 aluminum plate can’t reach. The processing technology is continuous casting. Rolling, which belongs to the series of hot-rolled aluminum sheets, can be used for oxidizing deep processing. Like China 5052 aluminum plate, it is one of China’s more mature aluminum coils. In fact, it is not difficult to find that the characteristics of 5052 aluminum coil are basically the same as those of the 5052 aluminum plate. Characteristics of 5052 aluminum coil that is also an Al-Mg alloy. The main alloying element is Mg. The magnesium content is between 3-5%. Therefore, it has very good molding processability. The 5052 aluminum properties mainly have low density and high tensile strength. High elongation, corrosion resistance, regarded by the industry as one of the most promising aluminum plates, can be widely used in gasoline or lubricating oil pipes, various liquid containers and other small load parts made with deep drawing, traffic vehicles , ship’s sheet metal parts, instruments, street lamp brackets and rivets, hardware products, electrical enclosures, etc.

5052 Aluminum Coil Properties

Mechanical Characteristics of 5052 Aluminum Coil

Tensile strength (σb): 170~305MPa

5052 Aluminum yield strength: σ0.2 (MPa) ≥ 65

Modulus of elasticity (E): 69.3~70.7Gpa

Density: 2.68 g / cm 3

The annealing temperature was 345 °C. The mechanical properties are different under different work hardening and heat treatment conditions.

Physical Characteristics of 5052 Aluminum Coil

5052 aluminum is very strong, especially high fatigue resistance. For example, the tensile strength of 1060 aluminum plate in 1-series is between 110-130 MPa, while the tensile strength characteristics of 5052 aluminum coil is 170-305 MPa. That is to say, the hardness of the 5052 is 100% higher than the hardness of 1060. In addition, the characteristics of 5052 aluminum coil including has good cold workability, high plasticity and corrosion resistance, good 5052 aluminum welding, low density and light weight. Under the same area, the 5052 aluminum coil weighs less than other series of aluminum coils, during semi-cold hardening. The plasticity is still good, the plasticity is low in cold work hardening, but its machinability is poor, but it can be polished.

Difference between Characteristics of 5052 Aluminum Coil vs 6061

5052 aluminum vs 6061 is the first difference in alloying elements. The 5052 aluminum coil alloy element is magnesium, and the element of the 6061 alloy contains silicon in addition to magnesium. Secondly, the 5052 aluminum vs 6061 processing status is different. The 6061 aluminum coil and the characteristics of 5052 aluminum coil have the O state. But, the 6061 aluminum coil is generally in the T6 and T651 states. The 5052 aluminum tempers are generally H112, H24 and H32. . The difference between these two points makes the 5052 aluminum vs 6061 different from performance to use. The 6061 aluminum coil is mostly used in various industrial structural parts with high strength requirements, and the characteristics of 5052 aluminum coil is mostly used for the environment of rust demand. 5052 aluminum bending is also allowed, 5052 aluminum sheet is also bendable, but the 6061 aluminum plate is much harder than the 5052 aluminum, it is generally not easy to be bent, and is often used in abrasive tools. 5052 aluminum bending performance and plasticity are also much stronger than the 6 series, so we should be treated selectively in practical applications.