Classification of aluminum plates

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

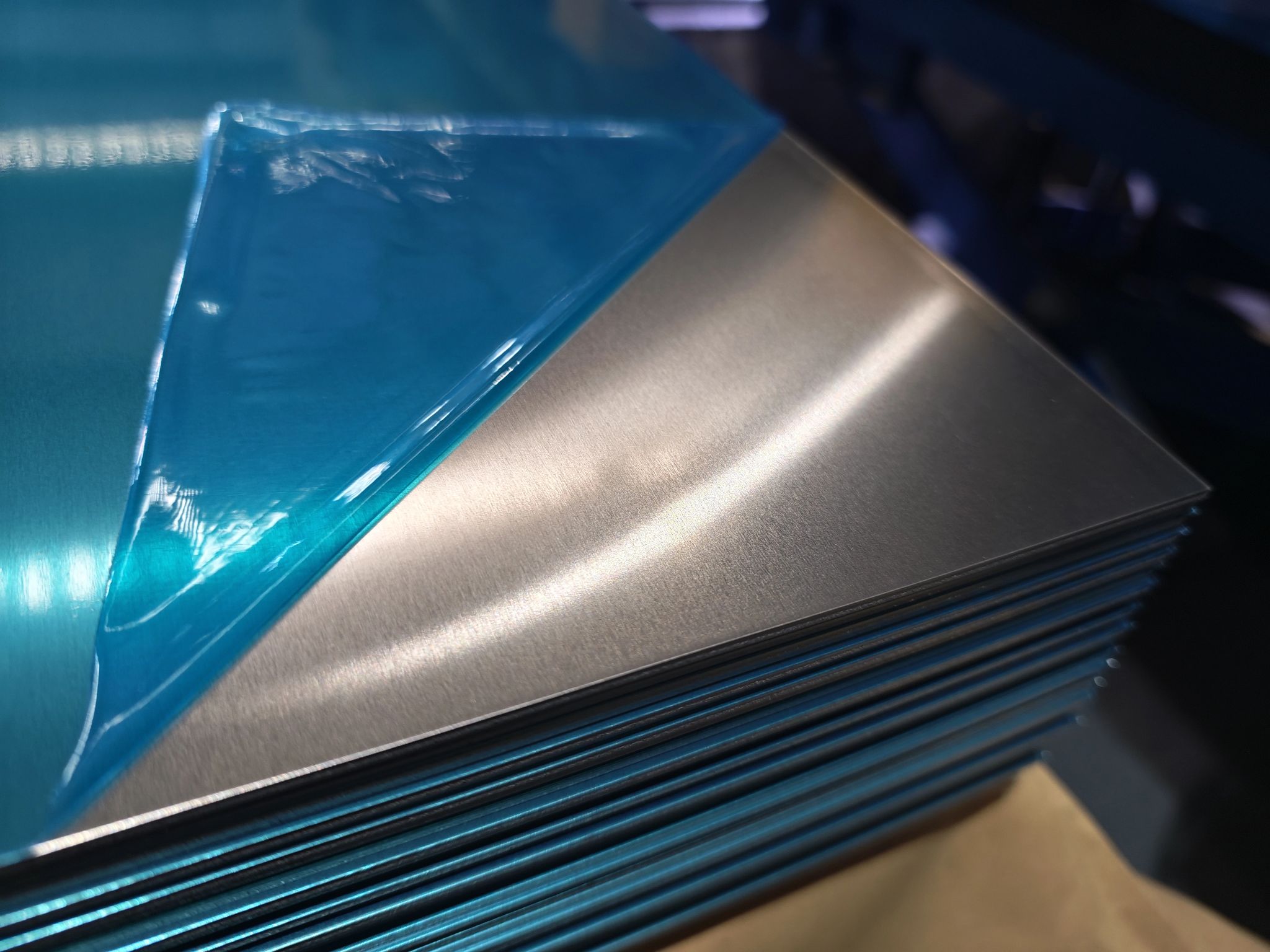

The aluminum plate refers to an aluminum plate material obtained by press working (shearing or sawing) with pure aluminum or alloy aluminum to obtain a rectangular cross section and a uniform thickness. The aluminum plate is a rolled product with a rectangular cross section and a uniform thickness and greater than 0.2 mm. The edges of the aluminum panels are trimmed or sawn and trimmed and delivered in a flat profile. The thickness of the aluminum plate does not exceed one tenth of the width, A thickness of less than 0.2 mm is called an aluminum foil.

Aluminum sheet forming method:

Casting method, plastic forming method, deep processing method.

According to the heat treatment characteristics of the alloy, the aluminum plate is divided into two categories: non-heat treatable reinforced aluminum alloy and heat treatable reinforced aluminum alloy.

1. Non-heat-treated reinforced aluminum alloys include pure aluminum (1 series), aluminum-manganese alloy (3 series), aluminum-magnesium alloy (5 series), and aluminum-silicon alloy (4 series).

2. Heat-treated reinforced aluminum alloy: aluminum-magnesium-silicon alloy (6 series), aluminum-copper alloy (2 series), aluminum-zinc-magnesium alloy (7 series), and the like.

Classification of aluminum plates:

Aluminum plate is divided into high-purity aluminum plate (aluminum content above 99.9%) according to aluminum alloy composition; pure aluminum plate (aluminum content is above 99.6%); alloy aluminum plate; composite aluminum plate.

According to the thickness, it is divided into thin plates (thickness between 0.2mm and 6.0mm); medium and thick plates (between 6.0mm and 200mm).

The aluminum plate can be divided into cold rolled aluminum plate and hot rolled aluminum plate according to different processing technology.

The use of aluminum panels:

1, lighting fixtures; 2, solar reflectors; 3, building appearance; 4, interior decoration: ceiling, wall, etc.; 5, furniture, cabinets; 6, elevator; 7, signs, nameplates, luggage; 8, automotive interior and exterior decoration; 9. Interior decoration: such as picture frame; 10. Home appliances: refrigerator, microwave oven, audio equipment, etc. 11, aerospace and military, such as China’s large aircraft manufacturing, shenzhou spacecraft series, satellites and other aspects; 12, mechanical parts processing; 13. Mould manufacturing; 14. Chemical engineering/insulation pipe coating, etc.