Difference between Cold Rolled Aluminum and Hot Rolled Aluminum

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Production Process of Cold Rolled Aluminum

In the aluminum plate industry, aluminum plates are classified in many categories. According to the production process is different, aluminum plates can be classified into cold rolled aluminum plates and hot rolled aluminum plates.

The difference between cold rolled aluminum plate and hot rolled aluminum sheet is mainly due to the difference in production process: Cold rolled aluminum is processed by a casting machine into a cast roll and processed by a cold rolling mill;

Production Process of Hot Rolled Aluminum

Hot rolled aluminum is heated by an aluminum ingot plate, smelted at a high temperature and cast into a slab, which is rolled by a hot rolling mill after being milled, homogenized annealed.

Difference between Cold Rolled Aluminum and Hot Rolled Aluminum

1.Price.Cold rolled aluminum plate is simple in process and cheaper than hot rolled aluminum plate.

2.The billet supply is different. They are different in the billet supply. Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip.

As for cold rolled aluminum, after the aluminum ingot is smelted, it is rolled into a strip by a caster. Compared with hot rolled material, the production efficiency is high, but defects such as composition segregation and inclusions are not easy to solve, and the quality is not as good as hot rolling.

3.The production process is different: cold rolling is processed by a casting machine into a cast roll (8mm thickness) and then processed by a cold rolling mill. While as for the hot rolling is performed by heating an aluminum ingot (400-500 mm thickness) and rolling it at a high temperature by a hot rolling mill.

4.Different performance. Hot rolled aluminum shows good surface quality, strong mechanical properties and ductility, and good oxidation effect.

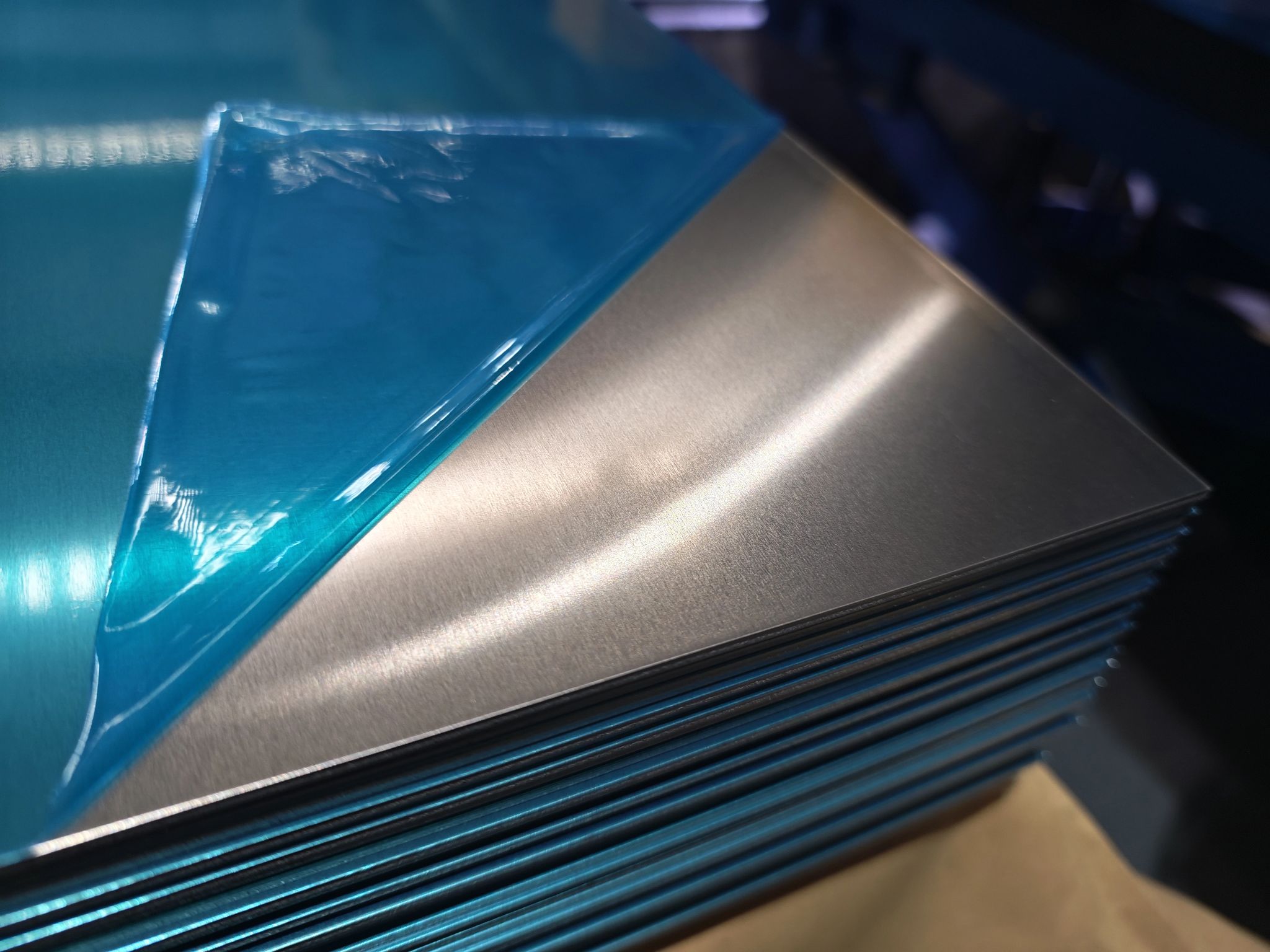

5.Differences between finished products. Generally, the elongation rate of cold-rolled final products is lower than that of hot-rolled final products. While in the casting state or hot rolled products, the surface of the product in the hot rolled state is usually brighter.

Features and Applications of Cold Rolled Aluminum and Hot Rolled Aluminum

Due to the different production processes, the performance of the cold rolled aluminum plate and the hot rolled aluminum plate is different: the surface of the hot rolled aluminum plate is good, the mechanical properties and the elongation property are strong, the oxidation effect is good.

Cold rolled aluminum plate is processed by hot-rolled aluminum plate at room temperature and is continuously cold-deformed by hot rolling. Its mechanical properties are relatively poor and the hardness is too high, so the cold rolled aluminum plate is mostly used in molds. Hot rolled aluminum plate is better for deep drawing and bending performance, so it is suitable for deep processing.

How to Distinguish between Cold Rolled Aluminum and Hot Rolled Aluminum?

Firstly, it can be judged by visual inspection. Generally, the surface of the hot rolled aluminum sheet is brighter. Secondly, the elongation can be tested. Generally, the elongation of the hot rolled aluminum plate is higher than that of the cold rolled aluminum plate. In addition, it can be seen through the crystal image. The difference is that hot rolling is a processed structure that has undergone hot deformation of more than 90%, and is simultaneously recrystallized during hot rolling, so the grain of the strip is fine and the properties are uniform, while the middle layer of the cold-rolled strip has a cast structure in which a feather-shaped columnar crystal is distributed.