The difference and Commonly used state of 6061 aluminum plate T6 and T5

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

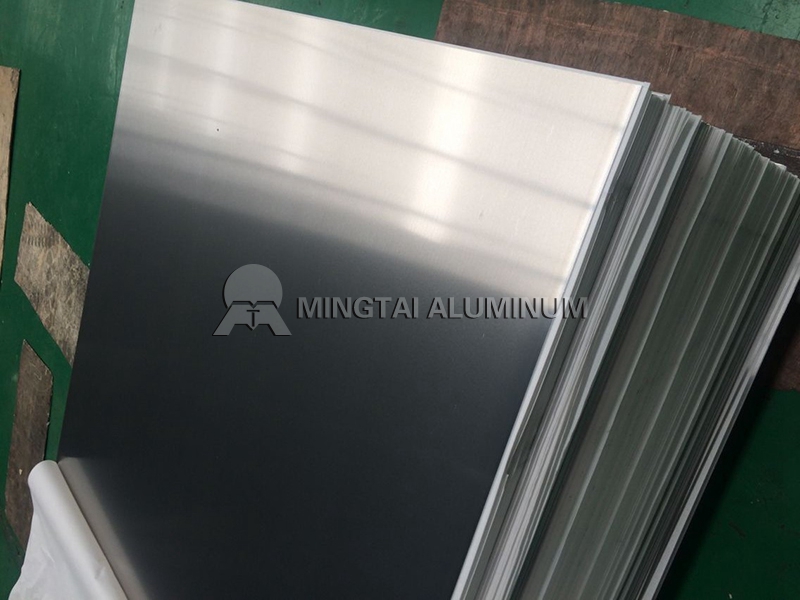

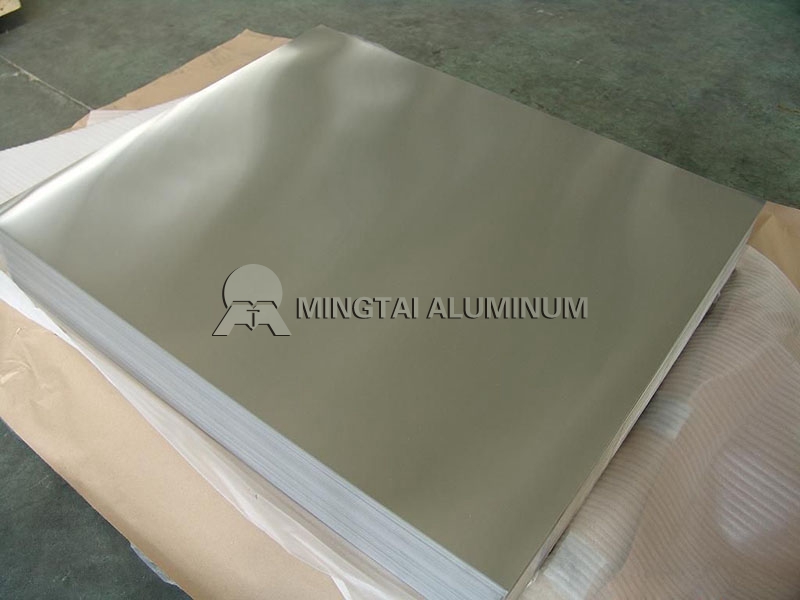

The main alloying elements of 6061 aluminum plate are magnesium and silicon, which have medium strength, good corrosion resistance and good oxidation effect. 6061 aluminum alloy thick plate is used in automatic mechanical parts, precision machining and various mold manufacturing.

The difference between 6061 aluminum plate T6 and T5:

6061 aluminum plate is the most commonly used product of 6 series aluminum plate. It belongs to aluminum magnesium silicon alloy. The most commonly used ones on the market are T6, T5 and so on. So where is the difference between T6 and T5?

First of all, in the production process, the aluminum alloy products of the 2, 6 and 7 series can be quenched to increase the strength of the aluminum plate. Quenching is to cool the alloy aluminum plate product to a certain temperature and then suddenly cool to achieve the required hardness of the product. This is the process that both T5 and T6 need to go through. The difference is that the 6061T6 aluminum plate means that the aluminum plate is cooled with water immediately after reaching a high temperature, so that the aluminum plate reaches the required hardness. However, T5 is rapidly cooled by air cooling after high temperature to achieve the required hardness. From the time point of view, T6 water cooling, that is, artificial aging takes a shorter time, but the natural aging of T5 air cooling takes 2-3 days. However, in the application, the T6 hardness is higher than T5, and the price per ton is higher than t5.

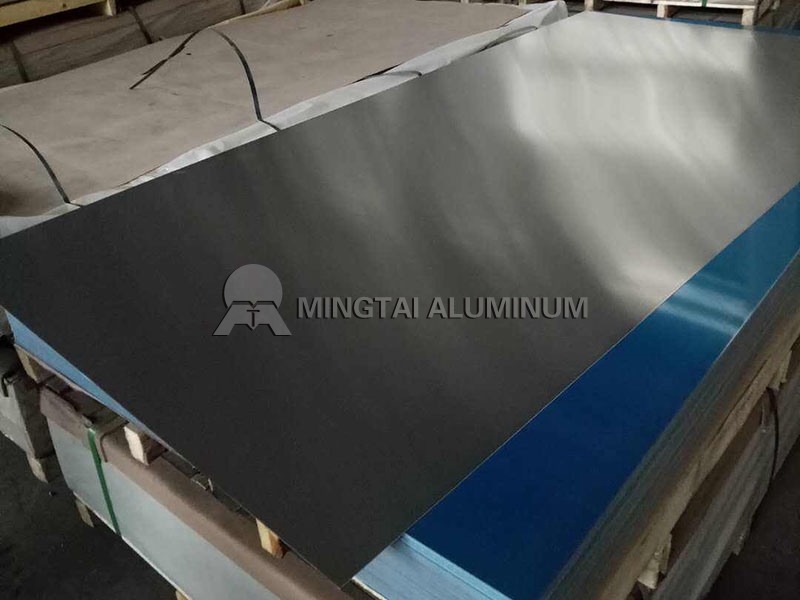

In addition, the 6061T651 commonly used in the market requires an additional stretching process. Because T651 is often used by customers for subsequent processing such as bending and deep drawing, the internal energy of the extruded aluminum sheet must be completely released by stretching. If it is not released, the surface of the aluminum sheet may be bent and waved later.

6061 aluminum plate common state:

The T6 state is the most used of 6061 aluminum alloy. The 6061 medium plate is quenched by medium and thick plate—-thick plate slicing—stretching machine—-aging treatment—-saw— – Polishing – packaging. The whole production cycle is about 10 days. After the solution heat treatment, it does not need to be cold-worked, and can be straightened and leveled without affecting the mechanical properties.

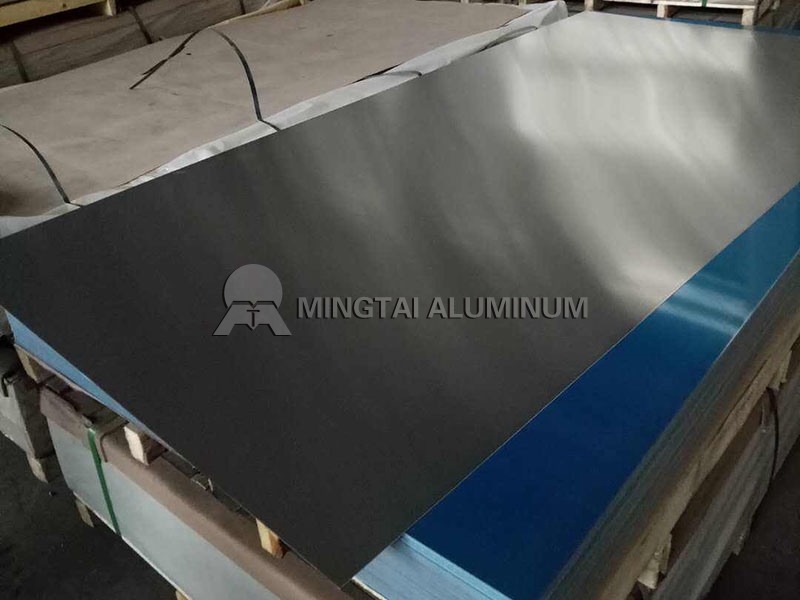

The F state is a free-processed state of 6061 aluminum alloy, which is suitable for special products for work hardening and heat treatment conditions during the molding process. F-state production cycle is very short: plate cutting—-saw—-polishing (also not polishing, according to customer requirements)—-packaging, the whole process is arranged smoothly for 3 days to ship, F-state mechanical properties Without specification, the customer can heat-process the F-state according to his own needs and use it in the required state. The corresponding price is also the cheapest.

The O state is a processed product in which the 6061 aluminum alloy is completely annealed to obtain the lowest strength. Applicable to the thin plate of 6061 aluminum alloy below 8.0, its production process: cold rolled finished product thickness, stretched and angled cleaning, fully annealed, flying sheared piece (or stretched and bent out finished product)—-package storage and other series Production, production cycle is second only to the T6 state.