Differences of Aluminum Tread Plate

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Differences of Aluminum Tread Plate

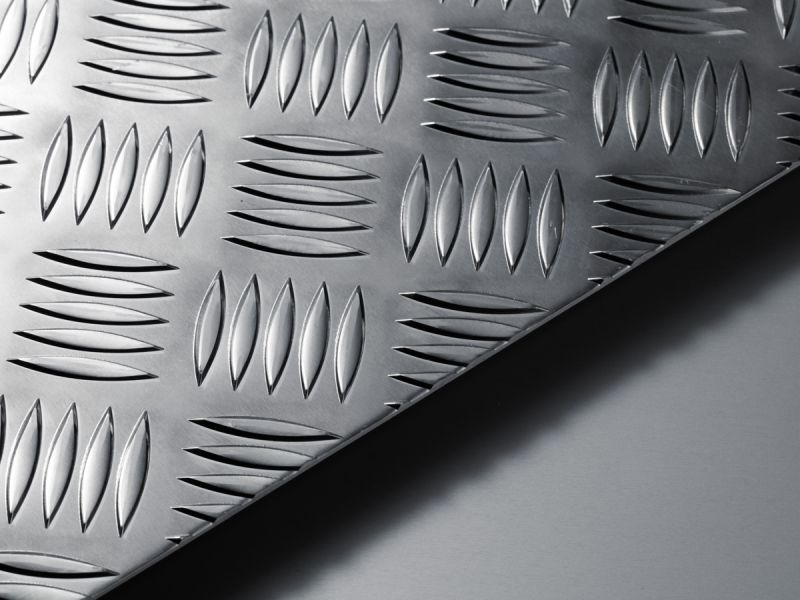

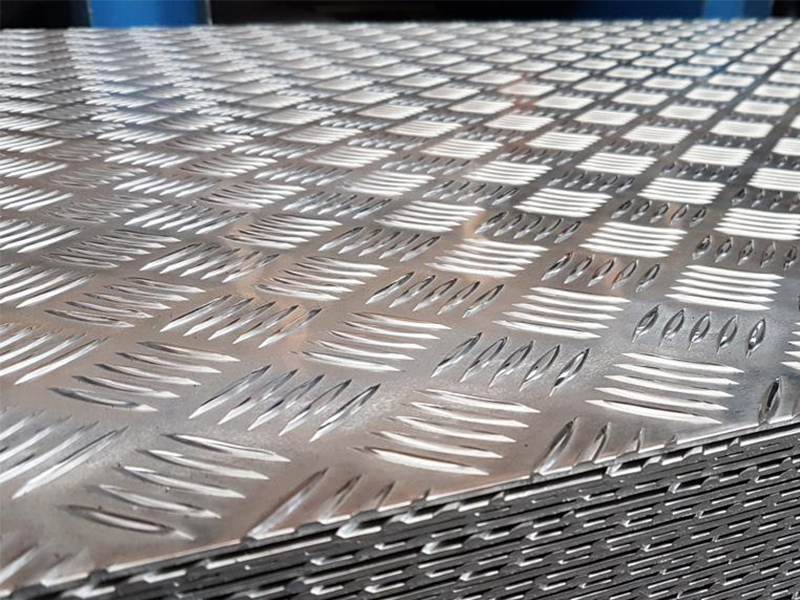

Aluminum tread plate is a commonly used aluminum plate. Unlike other ordinary aluminum plates, this aluminum plate shows different patterns on the surface of it, which is not only beautiful but also practical. There are many types of aluminum tread plate, there are 1 series, 3 series, 5 series aluminum tread plate, the most commonly used is aluminum diamond plate, then what is the difference between the various patterns of aluminum plate?

Aluminum tread plate is distinguished by the difference in alloy composition in addition to the patterned pattern. The aluminum plates produced by different alloy compositions are also different in actual use.

1 Series Aluminum Tread Plate

The common 1 Series aluminum tread plate is made of pure aluminum. Due to its simple process and low cost, it is mostly used in cold storage and vehicle floors. The commonly used representative grade is 1060 aluminum tread plate.

3 Series Aluminum Tread Plate

As for 3 series aluminum-manganese alloy aluminum tread plate, which is added with the alloying element manganese, Improving higher performance of it than ordinary aluminum tread plate. There are many advantages including high strength, strong impact resistance and so on. It also shows high corrosion resistance and rust resistance, commonly used in train cars, truck bodies and other places that are prone to rust. Representative grade products is 3003 aluminum tread plate.

5 Series Aluminum Tread Plate

The last thing mentioned is the 5-series aluminum-magnesium alloy aluminum tread plate, which is made of magnesium with high strength and high hardness. It also shows strong corrosion and rust resistance. 5 series aluminum tread plate is used In the marine and aerospace industries, The representative grade products of it is the 5052 aluminum tread plate.

Daily Cleaning Maintenance of Aluminum Tread Plate

Aluminum tread plate is a beautiful and practical, which is warmly welcomed by the manufacturers. However, in actual use, we should select it targetedly according to the performance of different alloy series. We also need to clean and maintain the surface of the tread plate regularly.

1. Unregulated use

Unregulated use can cause contamination on the surface of the aluminum plate, especially when it is contaminated with alkaline solution during the use of aluminum tread plate, which may cause corrosion on the surface of the aluminum plate, leaving a thin alkaline film on the surface, so as to affect the visual beauty of it. we do not have to worry too much about such pollution, just use a mild alkaline cleaner with warm water to clean.

2. Contaminated by acidic substances

Whether it is alkali or acidic, once it reaches a certain concentration, it will cause damage to the surface of aluminum tread plate. For this kind of pollution source, we can use brushing method to effectively clean. The general residue can be washed with flowing water. For special residues, tools and chemicals need to be used for cleaning.

3. Exposed to the air for a long time

If the aluminum tread plate is exposed to the air for a long time, especially if the air environment is humid, it may cause corrosion on the surface of the aluminum tread plate. In this case, the ordinary aluminum tread plate needs to be dealt with corrosion-resistant. As for high-quality corrosion-resistant aluminum tread plate generally forms an oxide film on the surface of it, and the presence of this film can help us prevent deeper oxidative corrosion. When cleaning, you can use the brushing method for the surface stains of the plate, and then rinse it repeatedly with water. Using the above method, the aluminum tread plate can be washed more cleanly.