Which Grade of Aluminum Alloy is Used for Mold Aluminum?

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Requirement about Mold Aluminum

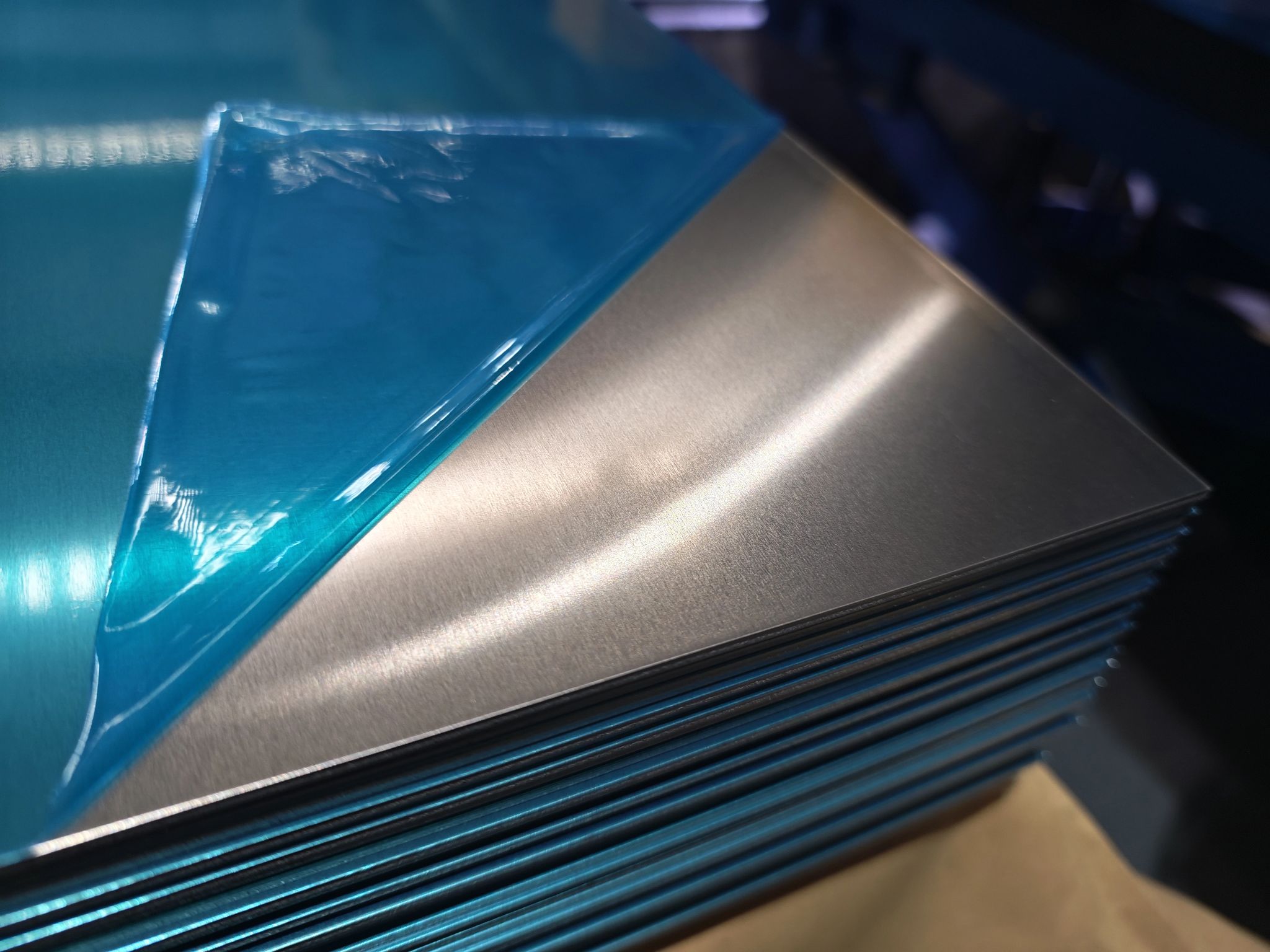

There are many aluminum sheets that can be used as molds, but the mold aluminum that we generally use is a high-strength and heat-treatable aluminum alloy, because of the aluminum sheets used for the molds need to have good mechanical properties, workability, and ease of processing. In some cases, the mold aluminum sheet also needs to have corrosion resistance and oxidation resistance requirements.

What Aluminum Alloy is Used for Mold Aluminum?

Which grade of the many aluminum sheet products from the 1 series to the 8 series are more suitable for mold aluminum? According to our experience, the aluminum plates that we often use in mold manufacturing mainly include 2 series, 5 series, 6 series, 7 series aluminum alloys, 5 series and 6 series products are medium hardness, 2 series and 7 series are super hard alloys.

Among the series of products, the 5 series is an aluminum alloy with magnesium as the main alloying element, also known as magnesium aluminum alloy, and its alloy state mainly includes O state, HXX and HXXX state.

5083 Mold Aluminum

The 5083 aluminum plate in the 5 series is a series of hot rolled aluminum plates. 5083 aluminum plate has good forming processability, corrosion resistance, weldability and oxidative deep processing performance, which is the best choice for mold aluminum.

6061 Mold Aluminum

However, after the heat treatment pre-stretching process, the strength of 6 series 6061 aluminum plate can not be compared with the 2XXX series or the 7XXX series, but the magnesium and silicon alloys have many characteristics, and have good processing properties and excellent welding characteristics. It is also a rare mold aluminum plate material, and it has excellent electroplating property, corrosion resistance, high toughness and no deformation after processing. It is also a compact and defect-free material, and easy to polish, easy to paint. It shows excellent oxidation effect.

6082 Mold Aluminum

6082 aluminum plate mainly has two states of O state and T state. O state is annealed state suitable for processed products with minimum strength after complete annealing; T state is heat treatment state, different from other states, suitable for heat treatment, after or not after work hardening to achieve a stable product.

The O and T4 states of the 6082 aluminum plate are suitable for bending and forming applications, and the T5 and T6 states are suitable for molds with good machinability requirements.

2A12/7075 Mold Aluminum

The above alloy aluminum plate has medium strength, good corrosion resistance and weldability, and can be widely applied to various industrial mold structural parts requiring a certain strength. If a higher strength aluminum alloy product is required, it can be selected in the 2 series or 7 series, like the 2A12 aluminum plate in the 2 series, and the 7075 aluminum plate in the 7 series, which are all good material for mold making.