The importance of 8011 medicinal aluminum foil

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Classification of Commonly Used Aluminum Foil

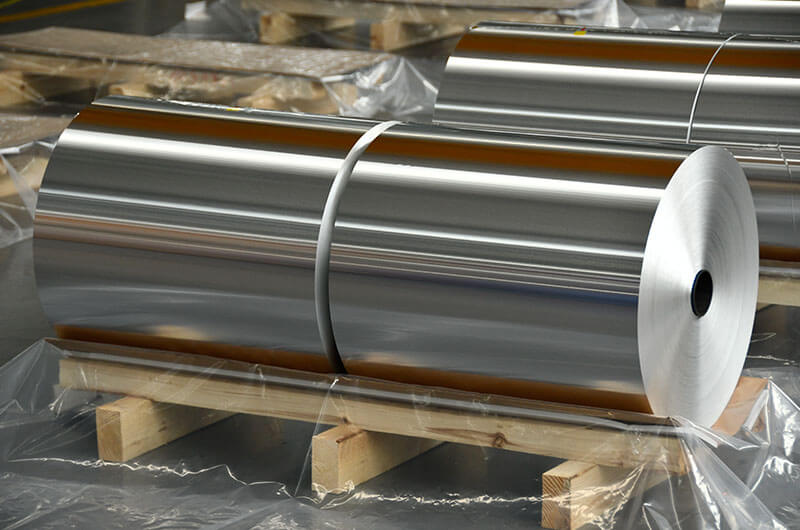

Aluminium foil is a kind of hot stamping material that directly rolled into thin sheets by Aluminium. It is soft, ductile, silvery white, easy to process, printable, and mass produced. At present, it is mainly used in the three fields of packaging, transportation and construction. The commonly used aluminum foils are classified as follows.

1、Household foil, tableware foil

The shelf life of household aluminum foil is about five times longer than that of plastic bags of the same thickness. It is widely used in food preservation, barbecue, aviation, hotel catering and kitchen aluminum foil container. A commonly used raw material is a 8011–0 aluminum foil having a thickness of 0.014–0.08 mm.

2、Soft packaging foil for medicines and foods

It can be sealed with new environmentally friendly sheets of pp, ps, pe and other materials, and becomes an environmentally friendly packaging product. Widely used in PTP pharmaceutical packaging, medicine lids, yogurt lids, food foil containers, etc. And it has the advantage of convenient and fast integrated automatic packaging, and is the best-selling product today. Commonly used 8021-O aluminum alloy, 8079-O aluminum alloy, 8011 aluminum foil with O state or H18, thickness 0.014 – 0.24mm.

3、The traffic field

Aluminum foil has a light texture and high electrical conductivity, making it the best material for film capacitors. For the current environmentally and friendly electric traffic field, the power reserve of electric vehicle has greatly helped.

4、The construction field

In China, aluminum foil is used as insulation material outside the central air-conditioning duct. In developed countries and regions, composite materials of aluminum foil, plastic and woven fiber are used to make the roof of the building.

Advantages of 8011 Medicine Aluminum Foil

1.8011 belongs to the 8××× Al-Fe-Si series alloy, which is commonly used for aluminum foil. Aluminum sheet is not commonly used. Due to the main elements of Fe and Si, the elongation and puncture resistance are strong, the oxidation reaction is not easy to occur, the stability is high, and processed into packaging with low processing cost.

2.The extruded 8-series alloy flakes are crucated on an offset paper with a material such as sodium silicate to form an aluminum foil, which can be printed, and satisfies the text printing requirements of PTP pharmaceutical packaging and other pharmaceutical packaging back sheets.

3. The most important is non-toxic and tasteless with food grade. It is in line with national pharmaceutical packaging standards, to maximize the safety and hygiene of drugs.

Notes for purchasing 8011 medicinal aluminum foil

1. Look at the surface of 8011 medicine aluminum foil

No oil, no crystal, no black lines, no pinholes, no yellow spots, no curling.

2.Field assessment.

Learn about the factory’s production process, assess the quality of unprocessed blanks, and the status of production equipment.

3.8011 aluminum foil suppliers whether there is a relevant production certificate from national certification .

Purchase of 8011 Medicinal Aluminum Foil Why Choose Mingtai

1.Mingtai 8011 medicine aluminum foil has brush A grade, clean surface, uniform color, no spots, no pinholes.

2.Mingtai strictly tests the quality of the blank from the source. During the rolling process, through regular cleaning of the rolls and control of roughness, selection of rolling oil, reduction of viscosity of rolling oil and control of machine running speed, etc. Control surface quality and strictly manufacture a safe and hygienic medicine aluminum foil.

3.Non-toxic, tasteless, safe and hygienic. Mingtai has excellent equipment, strictly enforces industry standards in safety production, and strictly carries out various inspections on bacteria, molds, etc. Its heavy metal content does not exceed 0.25% of the ppm, and multiple experiments are checked to ensure 8011 medicine aluminum foil is chemically stable, non-toxic and tasteless.

4.It has excellent moisture resistance, shading and high barrier ability, strong mechanical properties, high anti-blasting performance and strong puncture and tear resistance. It is also easy to be compounded, printed, and glued.