Marine Grade Aluminum

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Introduction to Marine Grade Aluminum:

Mingtai has more than 20 years of experience in the development of Marine Grade Aluminum. Corrosion behavior occurs in aluminum and aluminum alloys in seawater and marine atmosphere. Corrosion is the damage and deterioration of materials under the influence of environment. Mingtai’s 5083 aluminum plate is known for its superior strength and performance in extreme environments and is one of the main plates in Marine Grade Aluminum.

Corrosion Resistance of Marine Grade Aluminum:

Aluminum and most aluminum alloys have a relatively high degree of corrosion resistance because they form a thin, dense AL203 film on their surface in air very quickly, with a thickness of only 5 nm and the same color as aluminum. Generally, the oxide film is stable in a solution of pH 4.0 to 9.0, and is stable in concentrated nitric acid (pH = 1) and ammonium hydroxide (pH = 13). After the surface of the Marine Grade Aluminum is mechanically damaged, A new oxide film will be formed immediately on the injured surface without further corrosion.

The potential of aluminum is largely determined by the insulating properties of the oxide film. Therefore, all factors that improve the compactness of the oxide film, increase the thickness of the oxide film, and improve the insulating properties of the oxide film, so as to improve the corrosion resistance. Conversely, any factor that reduces the effective protection of the oxide film, whether mechanical or chemical, will reduce the corrosion resistance of aluminum and aluminum alloys.

Corrosion of Aluminum by the Marine Atmosphere:

The main feature of the marine atmosphere is that it contains a large amount of salt. Because the waves and strong winds bring the seawater into the atmosphere, the water evaporates and is blown to the land by the monsoon or typhoon, which increases the salt content in the low-altitude atmosphere and has a great relationship with the distance from the sea. The indoor and outdoor salt spray content in the same location is also very different, the latter can be 4-6 times larger than the former. In the same area, the suburbs near the sea can be separated from the urban area by about 10 times.

Chlorine and chloride also are main impurities in the marine atmosphere. Their content has a great influence on the corrosion of Marine Grade Aluminum. For example, 2024 and 7075 alloys are resistant to corrosion in a clean atmosphere, but the chlorine content of the atmosphere is >1.0%, their corrosion rate rises sharply, especially when the relative humidity RH is greater than 65%.

The lower the sea, the higher the chloride content of the sea fog, and the more severe the corrosion of the aluminum structure in the environment. The chloride accelerates pitting, stress corrosion, intergranular corrosion and crevice corrosion of aluminum and aluminum alloys. Human sweat and salt contain urea and lactic acid. They are all mediums for corrosion of aluminum and aluminum alloys. Therefore, gloves should be worn when handling, processing and assembling aluminum and aluminum structures.

Mingtai Marine Grade Aluminum:

Mingtai Aluminum is a large Marine Grade Aluminum manufacturer. The 5083 aluminum plate is one of Mingtai’s superior products as Marine Grade Aluminum. It is used in ships: Commonly used in 5083H116/H321/H112 state.

Advantages of Mingtai 5083 Aluminum Plate:

1.Mingtai Aluminum’s 5083 marine aluminum plate has passed CCS China, The classification society certification, which have been successfully used on hulls such as yachts and cruise ships.

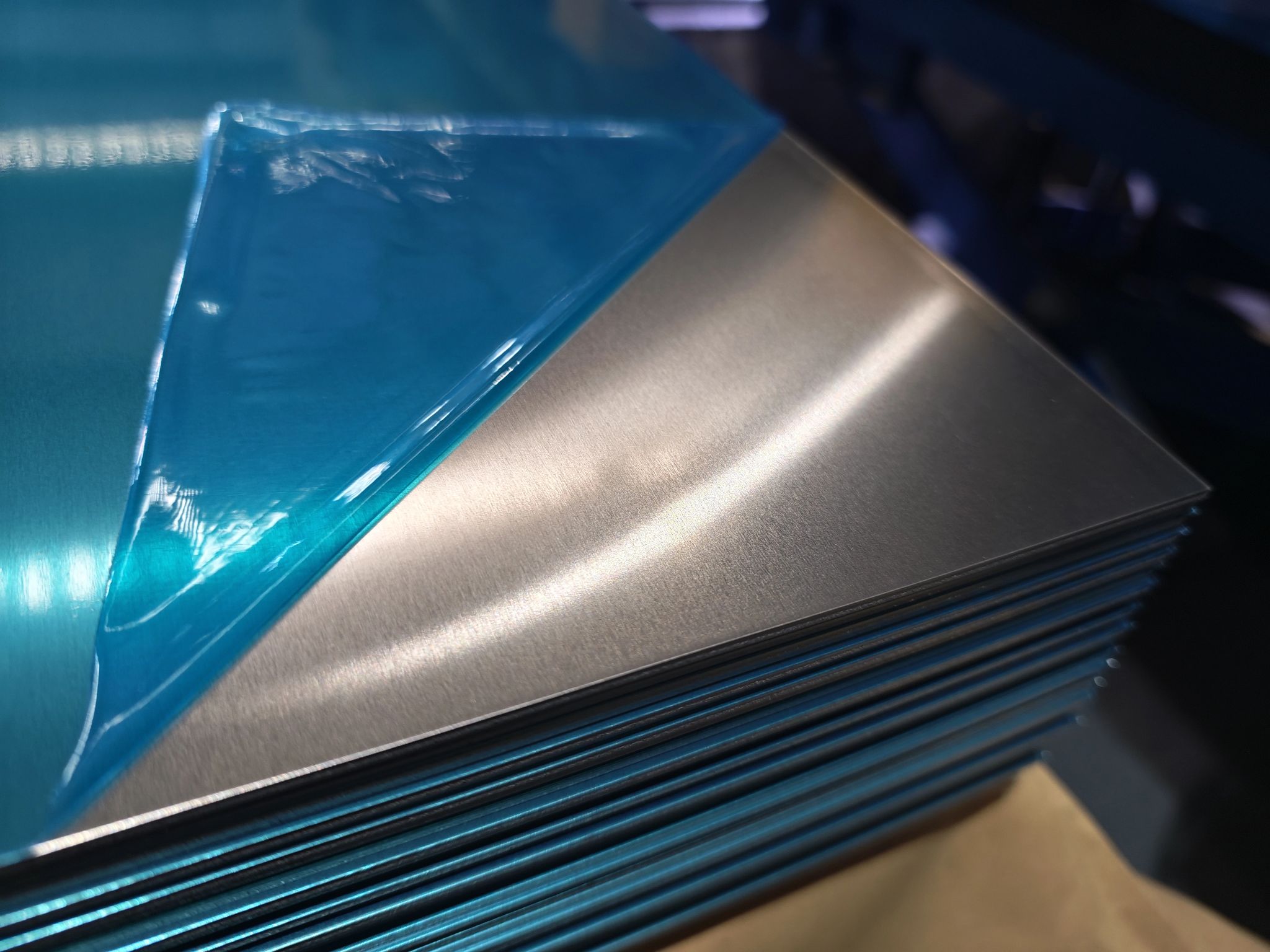

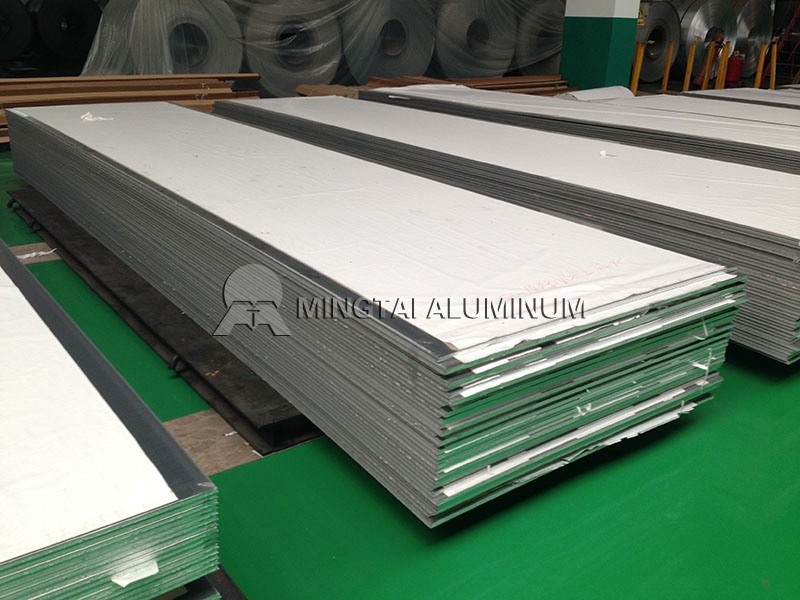

2, Mingtai 5083 aluminum plate has smooth and bright surface, its width up to 2600mm.

3.Mingtai addes a little bit of Be for 5083 aluminum plate to reduce the crack tendency of cast ingots and improve the surface quality of rolled plate.

4.The anti-corrosion performance of Mingtai 5083 aluminum plate is unquestionable.

Technical Parameters of Mingtai 5083 Aluminum Plate:

| Typical alloy | 5083 aluminum plate |

| Material status | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H 116, H321. |

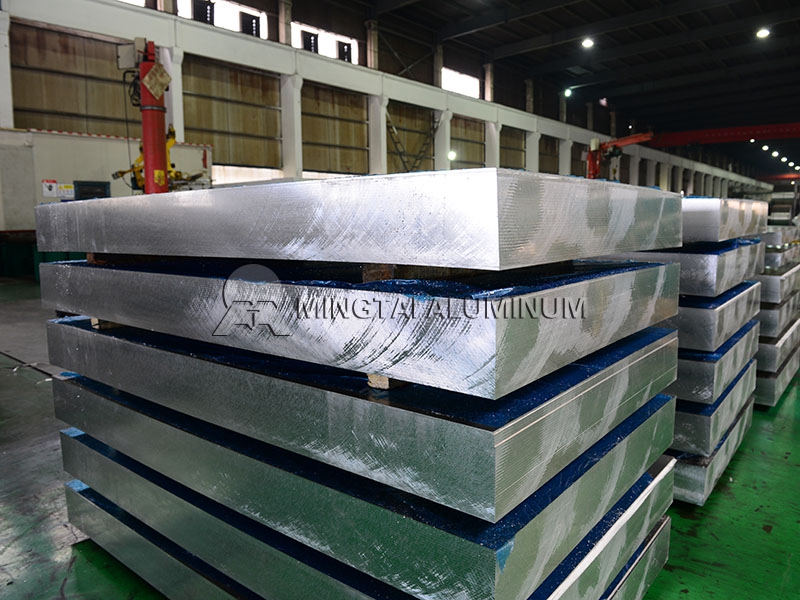

| Thickness (mm) | 0.15-500 |

| Width (mm) | 20-2650 |

| Length (mm) | 500-16000 |

| Typical product | Ship plate, LNG storage tank, gas storage cylinder, GIS housing, car body skin, flange material, etc. |