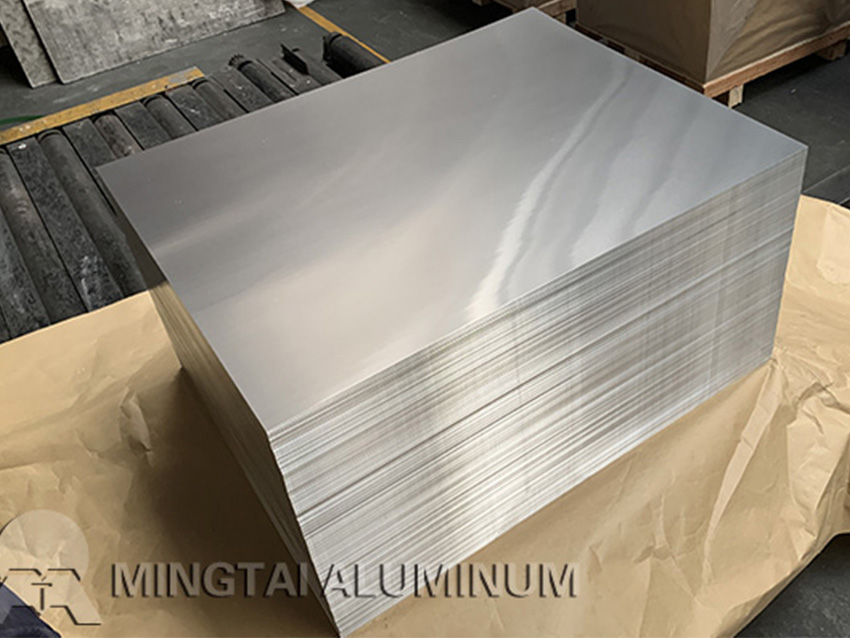

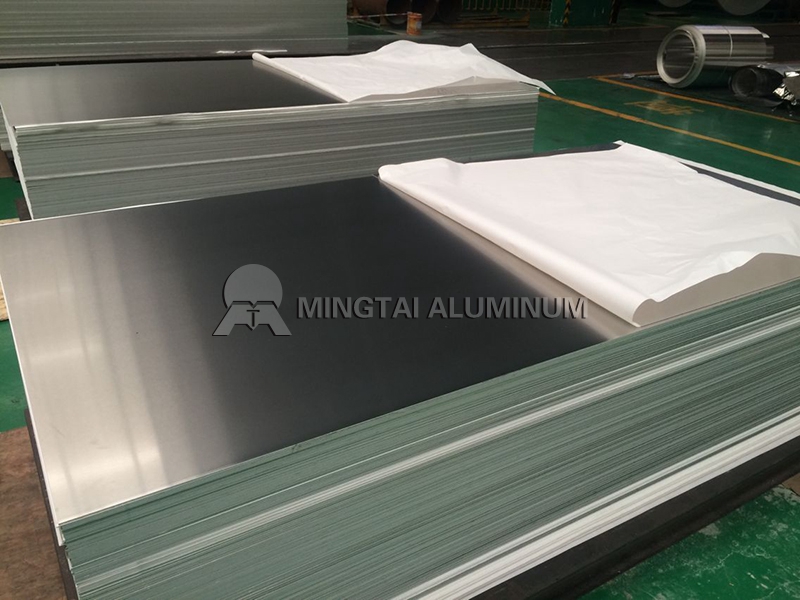

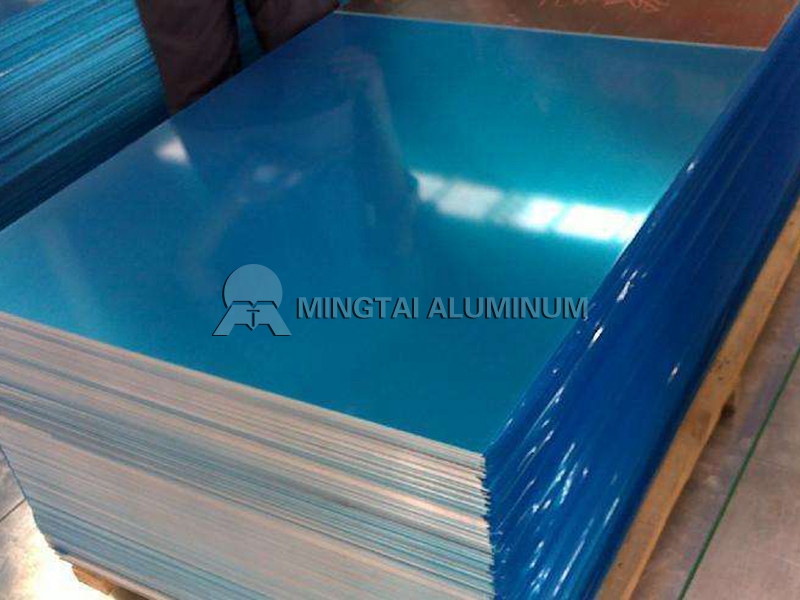

Mingtai quality 5052 aluminum plate supplier

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

5 series aluminum-magnesium alloy is applied, on behalf of the brand:

There are 5052、5005、5754、5454、5083、5154、5086、5A06, etc., with Mg as the main alloying element, because of its good anti-rust ability, it is often used as a rust-proof aluminum plate. Aluminum-magnesium alloys have many advantages. Many alloys of automobile manufacturers replace traditional materials and are used in automobile doors, steering wheels and engines to achieve lightweight vehicles. In addition, aluminum-magnesium alloys are also widely used in electronic products.

As far as the 5052 aluminum plate is concerned, it is often used on the outer casing of 3C products, and has the following advantages and disadvantages. Let’s take a look at Henan Mingtai Aluminum.

Advantages: 5052 aluminum plate has low density, good heat dissipation, good rigidity, long-term use, not easy to deform, corrosion-resistant, beautiful color, easy to color, can be changed into various colors through surface treatment process, and brighten the electronic products. The small density features make the electronic products carry. Therefore, many notebook computer products use aluminum-magnesium alloy casing technology.

Disadvantages: Aluminum-magnesium alloy is not very strong and wear-resistant, the cost is high, and the molding is difficult. Therefore, the notebook computer generally only uses aluminum-magnesium alloy on the top cover, and few organic types use aluminum-magnesium alloy to manufacture the whole casing.

Mingtai quality 5052 aluminum plate supplier

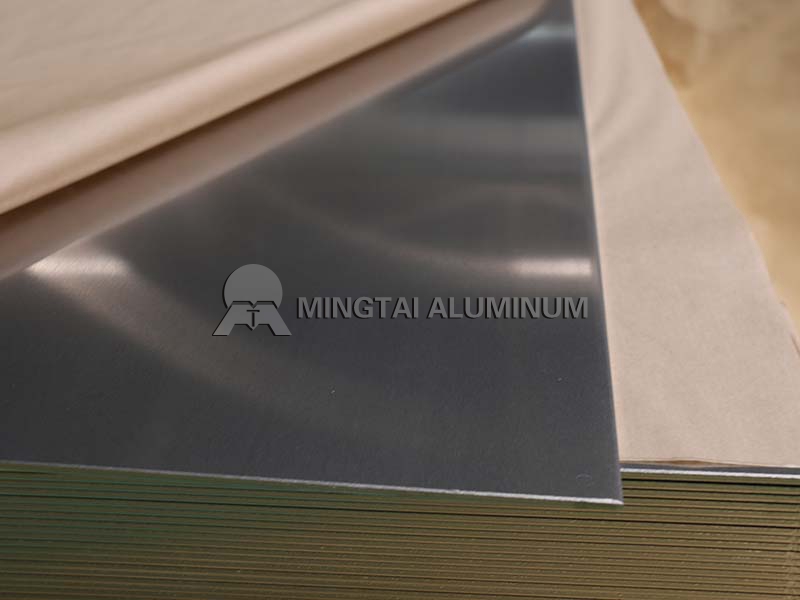

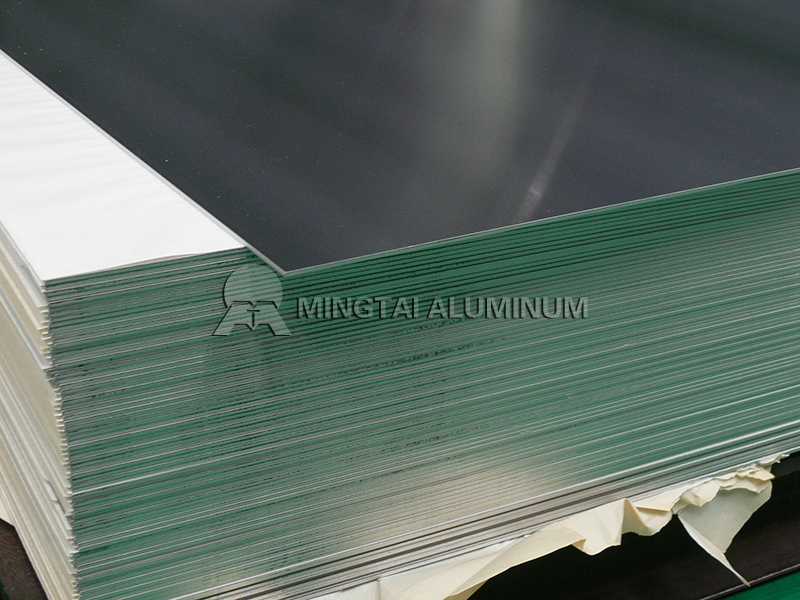

Oil staining often occurs during the production of aluminum sheets. Oil stain refers to the excessive oil on the surface of the aluminum tip after rolling, and the excess oil except the rolling oil film is carried. These oils have a greater hazard to the appearance of the aluminum plate. On the one hand, since the aluminum plate products are mostly used for decoration or packaging materials, the requirements for surface cleanliness are relatively high. On the other hand, too much oil on the surface of the aluminum plate can form excessive residues, which affects the use. Therefore, it is very important to reduce the oil stain and ensure the surface of the aluminum plate is clean.

Mingtai Aluminum has 20 years of experience in aluminum sheet processing and has a detailed understanding of the causes of oil stain formation. After analysis, it is found that these oils are mainly caused by the upper and lower sides of the roll neck or the exit of the rolling mill, splashing, dripping on the surface of the box, and the abnormality of the rolling mill’s roll-cleaning device, and the dripping of the mill’s thickness measuring head, and the composition is complicated. If you want to effectively reduce oil pollution, aluminum plate manufacturers should strictly check the production equipment before production. Once it is found that there is too much oil in the equipment, it should be cleaned in time and find the reason. At the same time, the aluminum board surface should be cleaned and processed. If the products cannot be cleaned, the products will be disposed of. Oily products are prohibited from entering the market and entering the market.

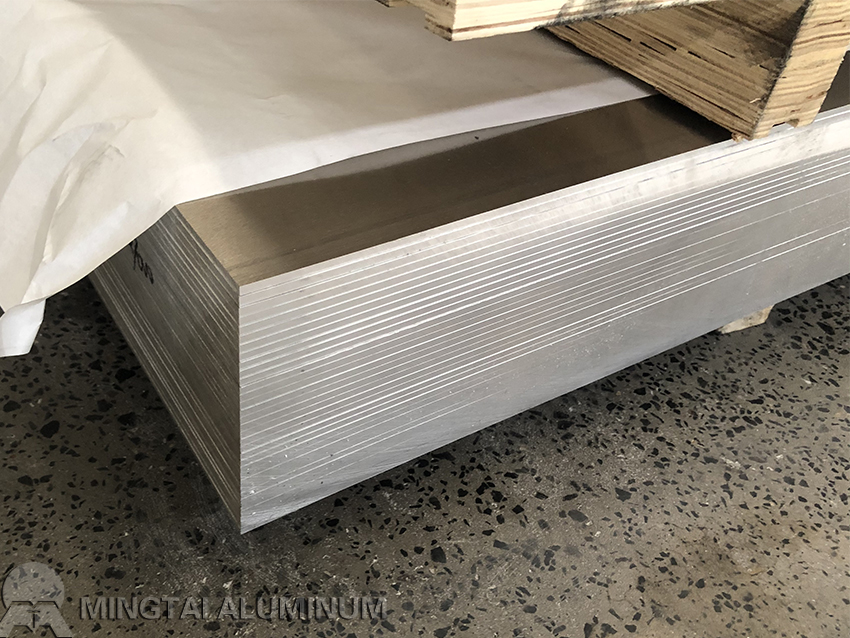

The market demand for 5052 aluminum plate is very high, and the domestic production technology is relatively mature. As the superior product of Mingtai Aluminum, 5052 aluminum plate has mature production technology, excellent quality and stable performance. It can undertake orders of 8-2000 tons, O-state and H-state, thickness 0.15-600mm. Welcome everyone to order!