Mingtai supplies aluminum sheets for injection molds

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Injection molds are a tool for producing plastic products; they are also tools that give plastic products complete structure and precise dimensions. Injection molding is a processing method used in mass production of complex parts of certain shapes.

According to the molding characteristics, the injection mold is divided into two types: thermosetting plastic mold thermoplastic plastic mold; according to the molding process, it is divided into plastic mold, blow mold, casting mold, thermoforming mold, hot stamping mold (compression molding), injection mold, etc. Among them, the hot stamping die can be divided into three types: overflow type, semi-overflow type and non-overflow type. The injection mold can be divided into cold runner mold and hot runner mold by the pouring system; Divided into mobile, fixed two.

Advantages of aluminum sheets for injection molds:

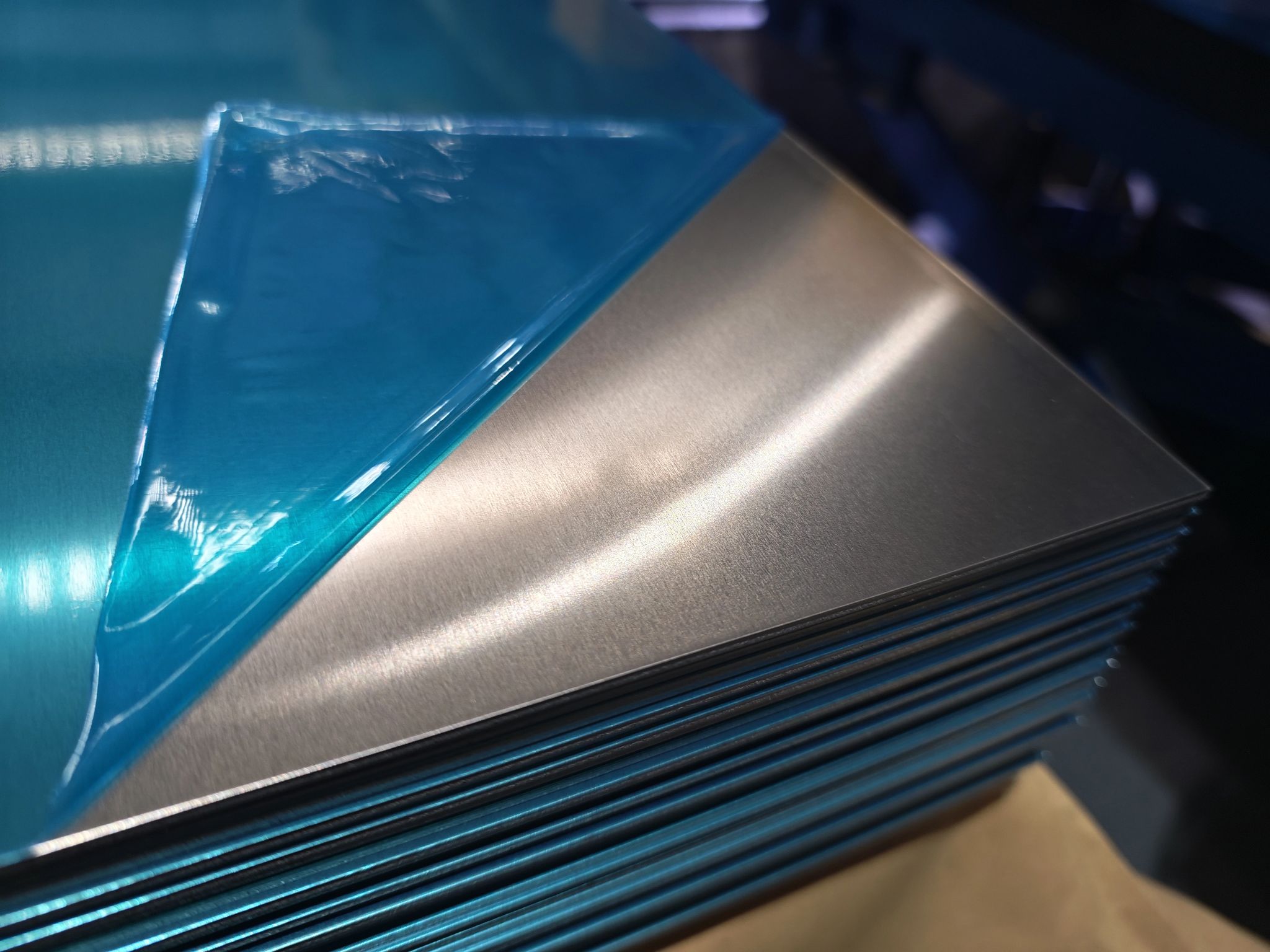

The traditional injection mold materials use more mold steel, and the surface maintenance of the mold is extremely important, it directly affects the surface quality of the product, the focus is to prevent corrosion, and the advantage of using aluminum sheet as the mold material is more obvious, the first is corrosion resistance. performance. Second, the weight is light. Since the density is only 36% of the general die steel, the motion inertia is relatively low, and it is relatively easy to add and decelerate during the production process, which can reduce the loss of the machine and the mold. It is easy to machine again and has high dimensional stability. The cutting speed is more than 6 times faster than the general die steel, so the mold processing time is greatly reduced, so that the mold can be produced faster. Finally excellent thermal conductivity. Its thermal conductivity is higher than that of general die steel, which can save 50% of the cold cutting time of the mold during production, thereby improving the production efficiency of the mold. With the development of the market, mold aluminum used in many industries has replaced steel as a mold material.

Mingtai supplies aluminum sheets for injection molds:

Injection molds generally use 6061 aluminum plate, 7075T651 aluminum, 2024 aluminum, and so on. The heat treatment is below 300 ° C thickness (diameter), the strength and hardness are basically the same; in high-speed machining, almost no deformation: perfect pre-stretching (T651) process, completely eliminate internal stress, not easy to warp during processing and stress Curvature, cracking and deformation; permanent deformation does not occur in a working environment of 400 °C.

Henan Mingtai Aluminum Co., Ltd. specializes in producing 1-8 aluminum plate and foil, covering a wide range of industrial aluminum. The products are certified by the World Standard, National Standard, GS and other quality. It is a senior listed company with a focus on aluminum processing for 20 years. The development of China’s aluminum processing industry.