Mold aluminum alloy material

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

The aluminum sheets required for mold aluminum are generally high strength heat treatable alloys that require good mechanical properties, workability, and ease of processing. According to the use and characteristics of the mold, the aluminum plate also needs to have corrosion resistance and oxidation resistance.

Alloy material of Mold aluminum:

Among the 1-8 series aluminum sheets, the aluminum sheets used for mold manufacturing mainly include medium-hard 5-series, 6-series alloys and 2-series 7-series alloys having a relatively high hardness. The 5 series is an aluminum alloy with magnesium as the main alloying element, also known as magnesium aluminum alloy, and its alloy state mainly includes the O state, the HXX and the HXXX state. The 6-series aluminum plate is an extruded alloy to which Al-Mg-Si element is added. Currently, more than 70% of the aluminum extrusion processed materials in the world are produced using a 6-series alloy.

5083 Mold aluminum:

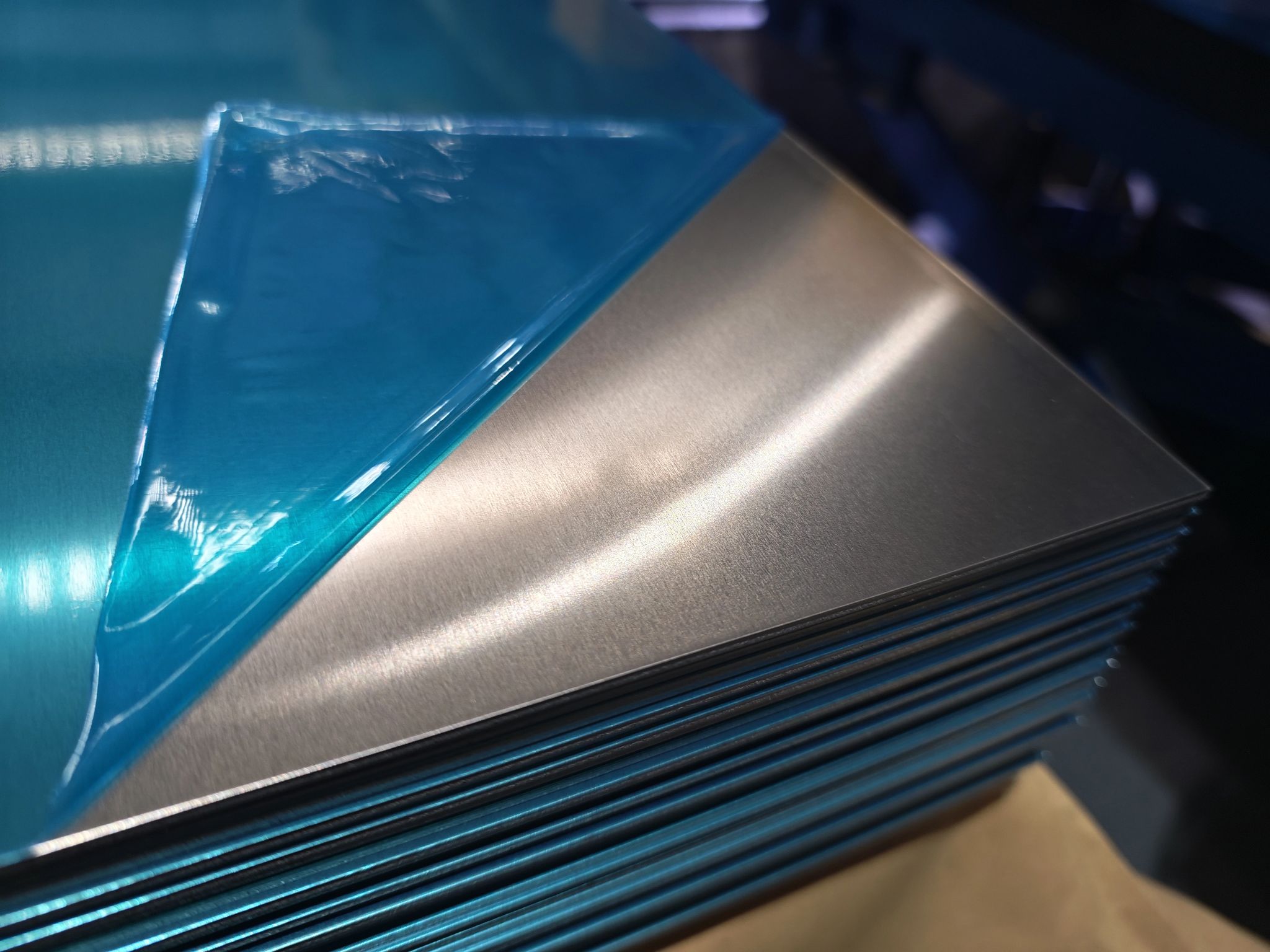

The 5083 aluminum plate belongs to the hot rolled aluminum plate series. The 5083 aluminum plate produced by Mingtai Aluminum Co., Ltd. adopts the processing technology of continuous casting and rolling, has good forming processability, corrosion resistance, weldability and deep processing performance, and is the best choice for Mold aluminum.

6061 Mold aluminum:

After the heat treatment pre-stretching process of Mingtai Aluminum 6061 aluminum plate, its strength can not be compared with 2XXX series or 7XXX series, but its magnesium and silicon alloy have many characteristics, and it has good processing performance and excellent welding characteristics. Moreover, it has high electroplating property, corrosion resistance, high toughness and no deformation after processing, compact and defect-free materials, easy to polish, easy to paint, and excellent oxidation effect.

6062 Mold aluminum:

The O and T4 states of the 6082 aluminum plate Mold aluminum are suitable for bending and forming applications, and the T5 and T6 states are suitable for molds with good machinability requirements. 6082 aluminum plate is better in corrosion resistance and wear resistance. Has good processing properties and excellent welding characteristics. Moreover, it has high electroplating property, corrosion resistance, high toughness and no deformation after processing, and the material is dense and has no defects. It can also be used in products with high requirements on the performance of finished products such as tank car bodies.

The above alloy aluminum plate has medium strength, good corrosion resistance and weldability, and can be widely applied to various industrial mold structural parts requiring a certain strength.

Mold aluminum application:

Mold aluminum sheets are widely used in aerospace fixtures, trucks, tower buildings, boats, pipelines and other applications where building, strength, weldability and corrosion resistance are required. Such as: aircraft parts, gears and shafts, fuse parts, instrument shafts and gears, missile parts jump valve parts, turbines, keys, aircraft, aerospace and defense applications.

The difference between Mold aluminum and die steel:

Mold aluminum has significant advantages over die steel:

1. Light weight. Since the density is only 36% of the general die steel, the motion inertia is relatively low, and it is relatively easy to add and decelerate during the production process, which can reduce the loss of the machine and the mold.

2. Easy machining and high dimensional stability. The cutting speed is more than 6 times faster than the general die steel, so the mold processing time is greatly reduced, so that the mold can be produced faster.

3. Excellent thermal conductivity. Its thermal conductivity is higher than that of general die steel, so it can save 50% of the cold cutting time of the mold during production, thereby improving the production efficiency of the mold.