Quality 4×8 Aluminum Plate How to Find

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Quality 4×8 Aluminum Plate How to Find

1.Firstly, we need to determine the usage, quantity and purchase location of the aluminum plate according need. If the amount is large, find the manufacturer, and the price and quality will be relatively good. If the amount is small, find the dealer, generally, the dealer has inventory, meanwhile, with a small amount, the price can be expensive.

2. After confirming the purchase quantity, compare the quality of the manufacturer or distributor’s products, then choose a reliable cooperation after comparison.

4×8 Aluminum Sheet Manufacturers and Distributors Differences

Currently, Aluminum sheet supplier on the market can be roughly divided into two types: one is aluminum sheet manufacturers, and the other is aluminum sheet suppliers. The following is the difference between 4×8 aluminum sheet manufacturers and distributors:

1.Aluminum plate manufacturers generally have MOQ requirements. Take Mingtai Aluminum as an example. If a customer purchases aluminum plates, the MOQ for each specification of aluminum plate is about 8-10 tons. But for manufacturers, they are self-produced and sold, their products price and after-sales will be relatively good.

2. As for aluminum plate distributors, usually get the goods from the manufacturers, and sell aluminum plates at a price increase. There is no requirement for the amount. Some distributors generally have inventory, and we can get the goods directly, but the price and after-sales are relatively less good than the manufacturer.

Aluminum Plate Quality Identification Skills

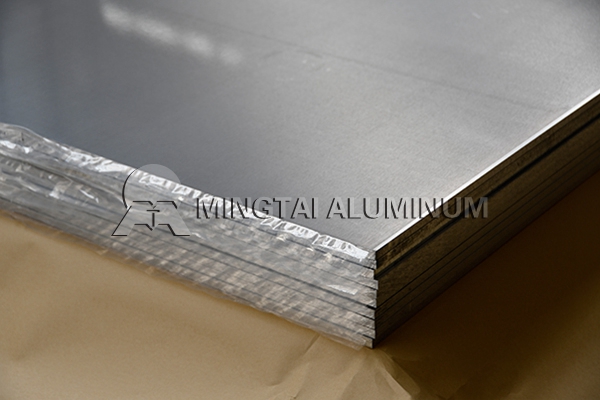

1.Firstly, when we choose the aluminum plate, we must first check the identification: whether the aluminum plate alloy and the packaging, are marked with the product certificate and production license number.

2.Surface Quality. In addition to the surface of the aluminum plate should be clean, no defects such as cracks, peeling, corrosion and bubbles are allowed, and no defects such as corrosion spots, electric burns (oxidized electrode points), black spots, and oxide film shedding are allowed. It also depends on the color and gloss of the aluminum plates surface, whether there is a color difference. The darker the color, the more impurities.

3.Oxide Film Thickness. The oxide film of the anodized aluminum plate is formed in the acid-base solution, by energizing both ends of the aluminum plates. It has protective and decorative effects, and can be detected by an eddy current thickness gauge. Generally, the thickness of the oxide film is between 8 and 15μ. The thicker the oxide film, the more resistant it is to corrosion, and the higher the cost of oxidation.

4.Hardness. The hardness of the general grade 6063 aluminum plate is between 8 and 12HW, measured with a Webster hardness tester. There are two main reasons that affect the hardness of aluminum plates: (1) the raw materials contain too much impurities; (2) the artificial aging temperature and time are not well controlled.

5. Corrosion Resistance. This index mainly affects the life of aluminum plates. Corrosion resistance inspections include copper accelerated acetic acid salt spray test and alkali drip test. Here we introduce the alkali drip test. That is, at 35℃±1℃, it will be approximately 10mg, 100g/L NaOH solution is dropped on the surface of the aluminum plate, visually observe the droplet until corrosion bubbling occurs, and calculate the penetration time of the oxide film. This test is easy to make rough judgments outdoors in summer, but in order to ensure the accuracy of the test, it must be carried out under the strict requirements of the laboratory.