How to solve the problem of 5052 aluminum plate dyeing

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

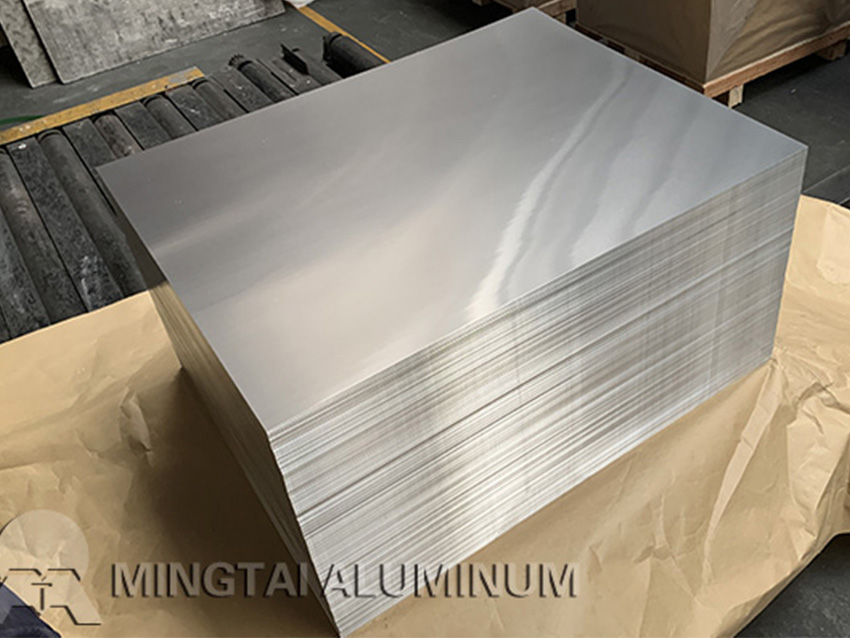

Today, aluminum sheets are used more and more widely in the construction market. The aluminum sheets used in construction include single-layer aluminum sheets and composite aluminum sheets. Among them, the 5052 aluminum plate is widely used. The 5052 aluminum plate processing requires very high cutting tools. The professional aluminum plate processing tool can improve the mechanical properties of the aluminum plate and reduce unnecessary aluminum chips and sticky knives. However, the 5052 aluminum plate may have dyeing problems in the processing, so how to solve the problem of 5052 aluminum board dyeing?

1. Control the thickness of the oxide film

The oxide film refers to the thickness, porosity, transparency, and the like of the aluminum film layer. The thickness of the film layer in the 5052 aluminum plate can be kept above 10 um, and the porosity and transparency can be obtained to obtain the best dyeing quality.

2. choose a good 5052 aluminum plate aluminum ingot

Usually, the high-purity aluminum, aluminum-magnesium, and aluminum-manganese alloys in the production process are anodized, and the dyeing function is the best, and can be dyed in various colors. For plates with relatively heavy silicon or copper, only dark and black can be dyed during the dyeing process, which is more monotonous.

3. control the temperature of the dyeing solution

The dyeing of 5052 aluminum plate is divided into cold dyeing and hot dyeing. The use of cold dyeing, the use of the process in the production process is relatively long, the dyed color uniformity is better. The time spent on thermal dyeing is relatively short, but the manipulation of color is more difficult. The temperature of the thermal dyeing is usually between 40 and 60 °C. If the temperature is too high, the adsorption of the dye is reduced, and the surface of the aluminum plate is easily embossed.

4. grasp the concentration of the dye solution

There is a relationship between the concentration of 5052 aluminum plate and dyeing. If the aluminum plate is lightly colored, the concentration can be lower, and the concentration of the dark color can be higher. Generally, the aluminum plate material produced is dyed with a lighter color of 0. 1-0. 39g/L, the dyed color is 1g/L, the dyed color is 3-5g/L, and the dyed dense color is 10- 15g / L, if the concentration of dyeing is relatively high, it will cause uneven color or floating color, and it is easy to appear “streaming” during cleaning and closing. In order to enhance the adsorption of dyeing, the dyeing is carried out using a low concentration of color, so that the dye molecules can penetrate into the pores of the oxide film more uniformly, which makes the dyed color more harmonious and firm.

As a 20-year-old aluminum processing enterprise, Mingtai aluminum can produce 1-8 series aluminum foil with foil, focusing on brand, integrity, service, cooperation and other codes of conduct. We are willing to provide you with professional selection suggestions with its rich professional knowledge and experience. Good processing, distribution and after-sales service.