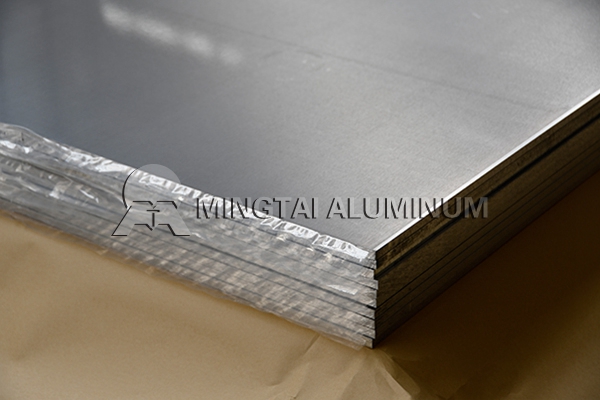

Stamped aluminum sheet

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Product introduction of stamped aluminum sheet

Stamped aluminum sheet products can be used in many fields. Such as automobile manufacturing, storage devices, tableware, electrical appliances, lighting components, etc. The main products are 1 series, 3 series, 5 series, 8 series aluminum plate and foil products.

Series 1 stamped aluminum sheet products include 1050 aluminum sheet, 1060 aluminum sheet, 1070 aluminum sheet, and 1100 aluminum sheet. 1 series aluminum products are pure aluminum, with aluminum content of 99% or more.

The 3 series stamped aluminum sheet products include 3003 aluminum sheet, 3004 aluminum sheet, 3005 aluminum sheet, 3104 aluminum sheet, and 3105 aluminum sheet. Among them, 3003 aluminum plate is widely used in battery shell materials, and 3104 aluminum plate and 3105 aluminum plate are mostly used in the production of cans.

The 8 series stamped aluminum sheet products are mainly aluminum foil. Especially 8011 aluminum foil, it is widely used in food packaging foil and medicine packaging.

The development of stamped aluminum sheet

With the development of my country’s economy and the advancement of science and technology, the speed of industrialization has also become faster and faster. In recent years, the automotive industry has developed rapidly all over the world. With the development of the automotive industry, the stamped aluminum sheet industry has also attracted attention from the machinery industry, whether domestic or foreign.

Stamped aluminum sheet process plays a very important role in automobile manufacturing. It can not only meet the automotive hardware conditions, such as performance, safety, environmental protection and long service life. It can also meet its price, energy saving and weight requirements. Not only saves money but also protects the environment and reduces environmental pollution.

The significance of stamped aluminum sheet to the automotive industry

Aluminum is the main group element in the third period of the periodic table. Its atomic weight is 26.9815, atomic number is 13, and its density is only 2.7g/cm3, which is only 1/3 of copper and iron. It has the same good performance as other non-ferrous metals. It can be seen that aluminum alloy material is one of the most ideal materials for lightweight production of automobiles.

In addition, aluminum has a strong high temperature performance, and its forming performance is also very good. It also has strong advantages in cutting performance and surface treatment performance. Therefore, the application of aluminum alloy materials has increased. For example, automobile manufacturing, navigation and aviation, bridge construction, electronic appliances, agricultural irrigation and drainage, household appliances, daily sports, etc. Hope that through the development of stamped aluminum sheet technology, the automobile manufacturing industry can also develop better.

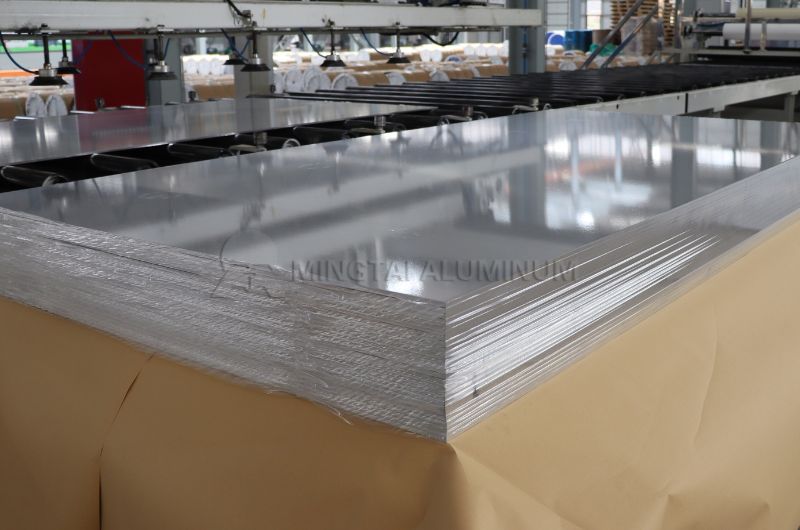

The product specifications of Mingtai stamped aluminum sheet manufacturer

| Alloy series | Typical alloy | Material state | thickness(mm) | width(mm) | Length(mm) |

| 1 series | 1050、1060、1070、1100 | O、H*2、*4、H18、H19

|

0.15-35 | 10-1700 | 500-16000 |

| 3 series | 3003、3004、3005、3104、3105 | ||||

| 5 series | 5182、5052 | ||||

| 8 series | 8011 |

Advantages of Mingtai stamped aluminum sheet products

1. Soaking technology, improve product plasticity.

The soaking technology mainly includes three stages of heating, heat preservation and cooling. It can eliminate internal stress, reduce intragranular segregation and unevenness of the structure, and greatly improve the stretchability and plasticity of the product.

2. The filtering technology makes the product beautiful and free of impurities.

It adopts multiple filtration processes such as glass cloth filtration, deep bed filtration, ceramic tube filtration and foam ceramic filtration. The purpose is to screen out impurity particles to ensure that the product is beautiful and free of impurities.

3. With advanced foil rolling mill, the thickness can be as thin as 0.02mm

The foil rolling machine adopts industry-leading ANDRITZ profile rolls and Honeywell thickness gauges, which can precisely control the product profile and export thickness. The product export thickness can be as small as 0.02mm and the width can reach 1800mm, satisfying different process requirements of customers.