Watchful Points About Purchase of Aluminum Plates

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Watchful Points About Purchase of Aluminum Plates

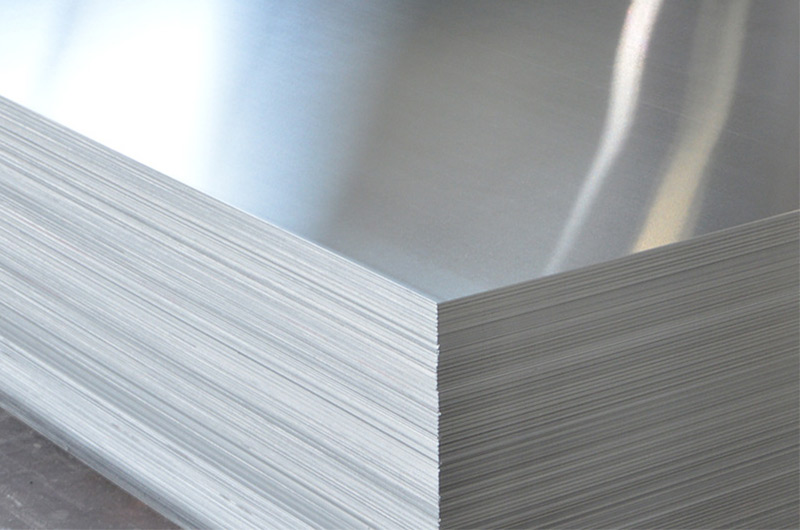

There are many alloy aluminum plate products, from 1 series to 8 series products, each has its own advantages and characteristics, which is also destined to correspond to different uses and needs when used. As consumers choose aluminum alloy materials, it is necessary to understand the various alloy aluminum plates to make it easier for us to make the right choice. The following questions need to be noted when purchasing products.

The strength of the alloy aluminum plate

Strength is one of the problems that need to be considered when using aluminum plates. If the strength is not up to the requirements, it will cause many problems. For example, the parts we processed cannot be used due to deformation,so strength is the key factor we consider. The main reason for the certain positive relationship between strength and hardness is that the alloy composition is different, and strength and hardness sequentially reduced from 7 series, 2 series, 4 series, 6 series, 5 series, 3 series, and 1 series. The 1 series of pure aluminum is the softest with the lowest strength. The alloy grades are 1060 aluminum plate and 1050 aluminum plate, while the 2 series and 7 series heat treatment alloys show the highest strength. In addition to different alloy composition of each alloy aluminum plate affecting the hardness, the processing state is also affected. Each alloy aluminum plate has the same influence on the processing state except for the difference in alloy composition. Therefore, when selecting the alloy plate, the series and state of the alloy should be taken into consideration.

Corrosion resistance of alloy aluminum plate

Corrosion resistance of alloy aluminum plate will affect the service life of it, especially for products working in high corrosion and harsh environment. It should pay attention to the corrosion resistance of alloy aluminum plate. Corrosion resistance of alloy aluminum plate includes chemical corrosion and stress resistance. Corrosion and other properties. In general, the corrosion resistance of 1 series pure aluminum is the best, and the 5 series is good. The alloy grades are 5052 aluminum plate, 5083 aluminum plate, 5754 aluminum plate, followed by 3 series and 6 series, 2 series and 7 series are poor. The principle of selection of corrosion resistance should be determined according to the environment in which it is used. For high-strength alloys used in corrosive environments, various anti-corrosion composites must be used.

Formability of alloy aluminum plate

Since the formability is related to the state, it is necessary to consider the strength range of various states after selecting the alloy aluminum plate grade. The low strength is easy to form, and the high strength is poor in formability. From the viewpoint of the alloy system, the 1 series shows the best formability, and the 3 series and the 5 series are preferable, and the 2 series and the 6 series are generally used, and the 7 series is basically incapable of forming. The state has a great influence on the formability of the aluminum alloy, and the formability in the annealed state (O state) is the best, and the formability in the state where the strength is higher is worse.

Weldability of alloy aluminum plate

The weldability of most aluminum alloys in 1-8 series aluminum plates is not a problem, especially some 5 series alloy aluminum plates are designed to improve the welding performance, but some 2 series and 7 series aluminum alloy grades are poor weldability, which we need to pay attention.