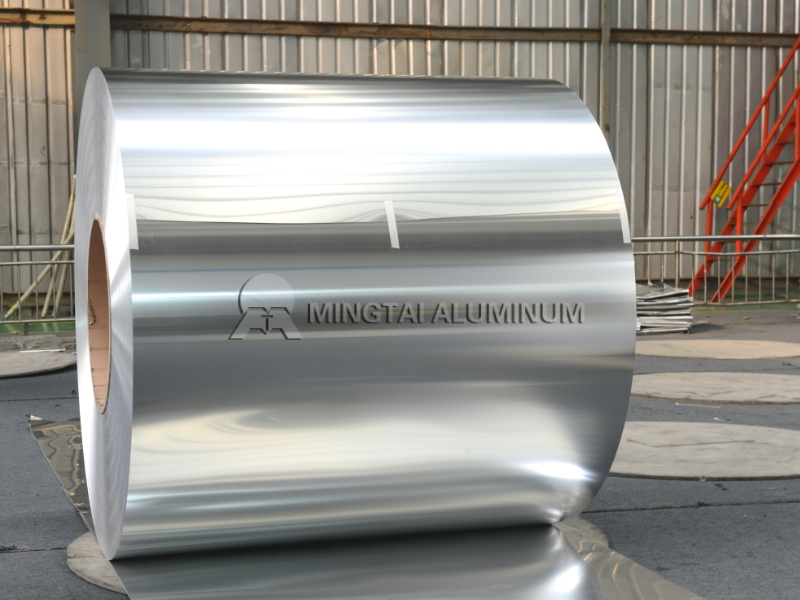

Width Precise 1070 Aluminum Coil Manufacturer

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

1070 Aluminum Coil Manufacturer Manufacturing Process

The 1070 aluminum coil manufacturer first performs an oil quenching and tempering process, and after forming a cold roll of 1070 aluminum plate, it is subjected to stress relief treatment, drawn to a predetermined size, and then annealed. After the softened 1070 aluminum plate is formed, it needs to be quenched and then tempered at medium temperature to obtain the desired mechanical properties. If there is no special performance requirement for the 1070 aluminum coil, there is no need for a second heat treatment, which is based on natural cooling.

Is the obtained aluminum alloy 1070 coil width inaccurate? The opening and slitting process of the 1070 aluminum coil manufacturer is particularly important. First, we know that the aluminum plate is flat. Here, taking 1070 aluminum as an example, the 1070 aluminum coil manufacturer divides the 1070 aluminum coil into a flat 1070 aluminum plate according to the user-specified size. After that, the 1070 aluminum plate formed here needs to be rolled into a roll, which becomes the aluminum alloy 1070 coil of the width specification required by us. The finished product we want will come out.

Mingtai 1070 Aluminum Coil Manufacturer Flatness and Slitting Level

Mingtai 1070 aluminum coil manufacturer accurately flatten

1. First, the Mingtai Strip Second Factory uses a row crane to hoist the 1070 aluminum coil on the unwinding trolley of the decoiler machine, keeping the direction of the aluminum coil in the same direction as the decoiler machine, and let the roll-in car slowly enter the decoiler machine. The lead is pressed against the aluminum coil and the auxiliary support is opened.

2. Secondly, open the shovel head and push the decoiler machine to introduce the aluminum plate into the bending and straightening machine. According to the thickness and width of the aluminum plate, adjust the bending and straightening machine to ensure the flatness of the 1070 aluminum plate.

3, Mingtai 1070 aluminum coil manufacturer professional technicians to control the main platform, open the front bridge, after the bridge, jog pull straightening machine, 1070 aluminum plate into the re-shaping machine, adjust the re-ighing machine, check the flatness of aluminum plate again and access to the fixed length machine, slitting machine.

4. Next, the 1070 aluminum coil manufacturer retracts the shovel head before and after the bridge. Jog the slitter to cut off the head and cut the 1070 aluminum plate according to the user’s required width specification. After the first 1070 aluminum plate is cut, Mingtai 1070 aluminum coil manufacturer will first check whether the quality is up to standard, assuring the flatness, length, width, diagonal size of the 1070 aluminum plate are accurate, and the board surface is defective. After passing the inspection, Mingtai 1070 aluminum coil manufacturer opened the conveyor and opened the automatic control, automatic production, and arranged for the professionals to observe at any time during the production process.

Mingtai 1070 aluminum coil manufacturer slitting equipment capacity

Mingtai 1070 aluminum coil manufacturer adopts slitting and flat-cutting slitting equipment according to the requirements of different width specifications of users when opening and cutting. Their processing ability is as follows.

Mingtai Slitting Machine Capacity

Mingtai slitting machine can enter aluminum alloy 1070 coil thickness 0.8-6mm, width 1000-2600mm, 1070 aluminum coil inner and outer diameter: 605/2400mm, 1070 aluminum coil maximum weight 24T, which means Mingtai 1070 aluminum coil manufacturer’s 1070 aluminum coil has a narrowest width of 200mm, which is what a few manufacturers can do.

Mingtai Decoiler Machine Capacity

Mingtai 1070 aluminum coil manufacturer has a flat shear thickness of 0.12-0.5mm, a width of 400-1250mm, a shear length of 500-2000, a length tolerance of ±0.3mm, a diagonal tolerance of ±0.5mm, and an annual throughput of 6,000 tons.

1070 Aluminum Coil Manufacturer Logistics Support

Having said that, Mingtai 1070 aluminum coil manufacturer professional mature 1070 aluminum coil processing technology, not only that, Mingtai 1070 aluminum foil coil is also outstanding. Henan Mingtai Aluminum Industry Co., Ltd. was established in 1997. It has more than 20 years of experience in manufacturing aluminum plate, coil, strip and foil. It is the first batch of China’s first independent research and development “1+4” and “1+1” hot rolling production lines, and put into use. With a production capacity of 750,000 tons, and a mature pre-sales consulting team, sales support team, manufacturing team, butler-type after-sales service team, four teams as a logistics support system, providing 360-degree global worry-free aluminum alloy 1070 coil purchase for global users Experience, click on the customer service consultation box on the right, welcome to consult!